Three-dimensional (3D) printing nozzle for preventing pipe expansion blockage

A 3D printing and nozzle technology, applied in the field of 3D printing nozzles, can solve problems such as blockage of expansion tubes, and achieve the effects of good lubricity, elimination of expansion tubes or even blockages, and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

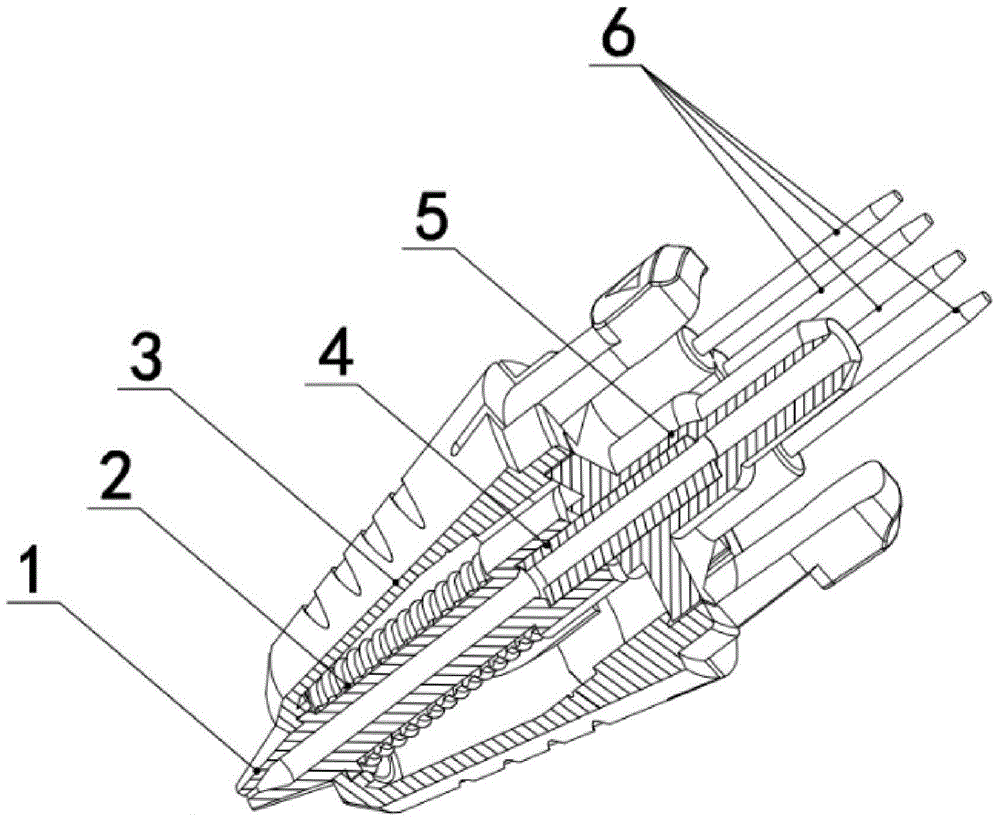

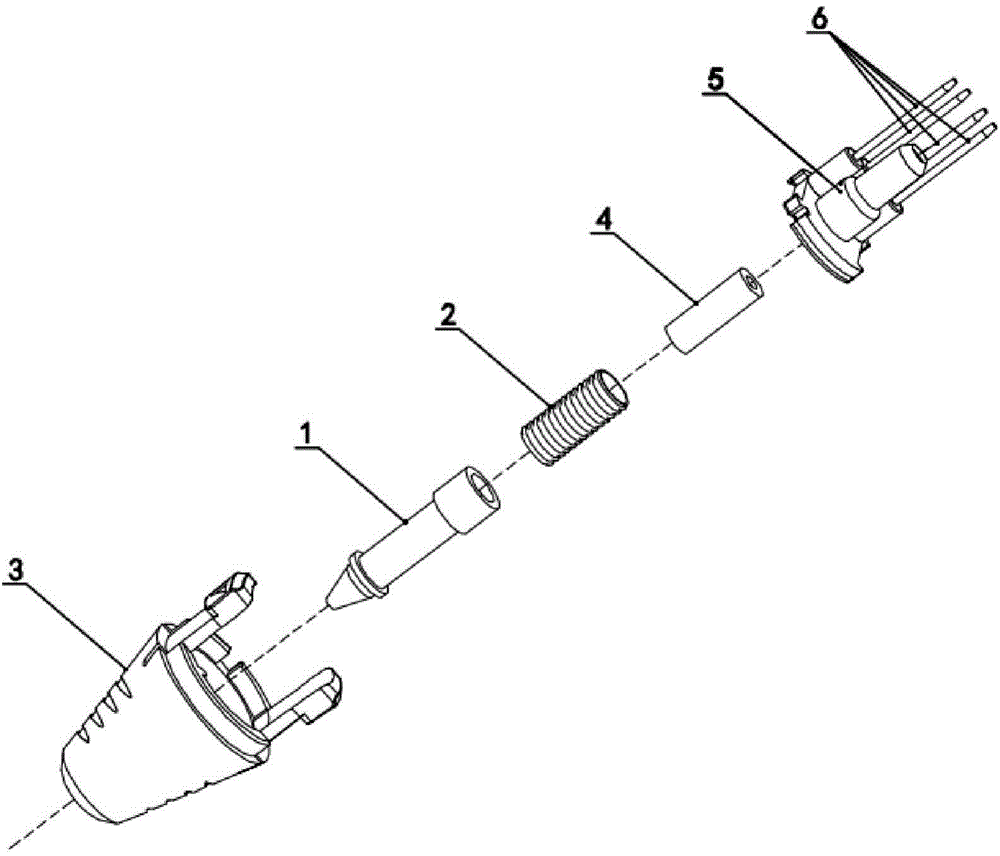

[0017] Embodiment 1: as figure 1 and figure 2 As shown, the anti-expansion tube blockage 3D printing nozzle of the present invention includes a nozzle 1 and a heating device 2 surrounding the outer wall of the nozzle 1, and also includes a plastic introduction tube 4, and the through hole of the plastic introduction tube 4 is formed by docking with the through hole of the nozzle 1 Consumable delivery cavity. Wherein the heating device 2 is a heating wire, and the plastic introduction pipe 4 is a polytetrafluoroethylene pipe.

Embodiment 2

[0018] Embodiment 2: as figure 1 and figure 2 As shown, the anti-expansion tube blockage 3D printing nozzle of the present invention includes a nozzle 1 and a heating device 2 surrounding the outer wall of the nozzle 1, and also includes a plastic introduction tube 4, and the through hole of the plastic introduction tube 4 is formed by docking with the through hole of the nozzle 1 Consumable delivery cavity. Wherein the heating device 2 is a metal film resistor formed by etching, and the plastic introduction tube 4 is a nylon tube.

Embodiment 3

[0019] Embodiment 3: as figure 1 and figure 2 As shown, the anti-expansion tube blockage 3D printing nozzle of the present invention includes a nozzle 1 and a heating device 2 surrounding the outer wall of the nozzle 1, and also includes a plastic introduction tube 4, and the through hole of the plastic introduction tube 4 is formed by docking with the through hole of the nozzle 1 Consumable delivery cavity. Wherein the heating device 2 is an annular heating device made of PTC ceramics, and the plastic introduction pipe 4 is an LCP pipe or a PPS pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com