Supporting piece used for preventing fast shrinkage of inner shell of crystallizer and application method thereof

A technology of supports and crystallizers, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of uneven fusion, quick change failure, and small opening, etc., to achieve easy operation, prevent deformation, prevent The effect of rapid contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

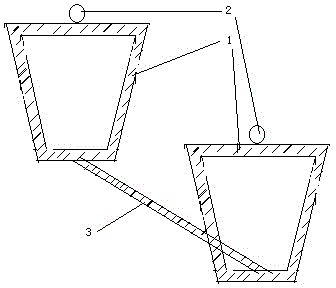

[0012] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a supporting piece for preventing rapid shrinkage of the billet shell in the crystallizer. The supporting piece is especially suitable for preventing the rapid shrinkage of the billet shell in the crystallizer during the quick change process of the large-section continuous casting tundish. The specific structure is: the supporting piece includes two weldments, the two weldments are welded and fixed together by a connecting beam 3, and a hook 2 is provided on one side of each weldment. The weldment selected here is trapezoidal weldment 1.

[0013] The invention also discloses a method for preventing rapid shrinkage of the slab shell in the crystallizer, the method is applied to the support, and the method includes the following steps:

[0014] 1) When the old tundish is raised to a high position and the pouring posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com