Laminated wafer processing method and adhesive sheet

A processing method and adhesive sheet technology, which can be used in metal processing equipment, manufacturing tools, laser welding equipment, etc., and can solve the problems of inability to form a modified layer at the condensing point, inability to divide laminated chips, and insufficient depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

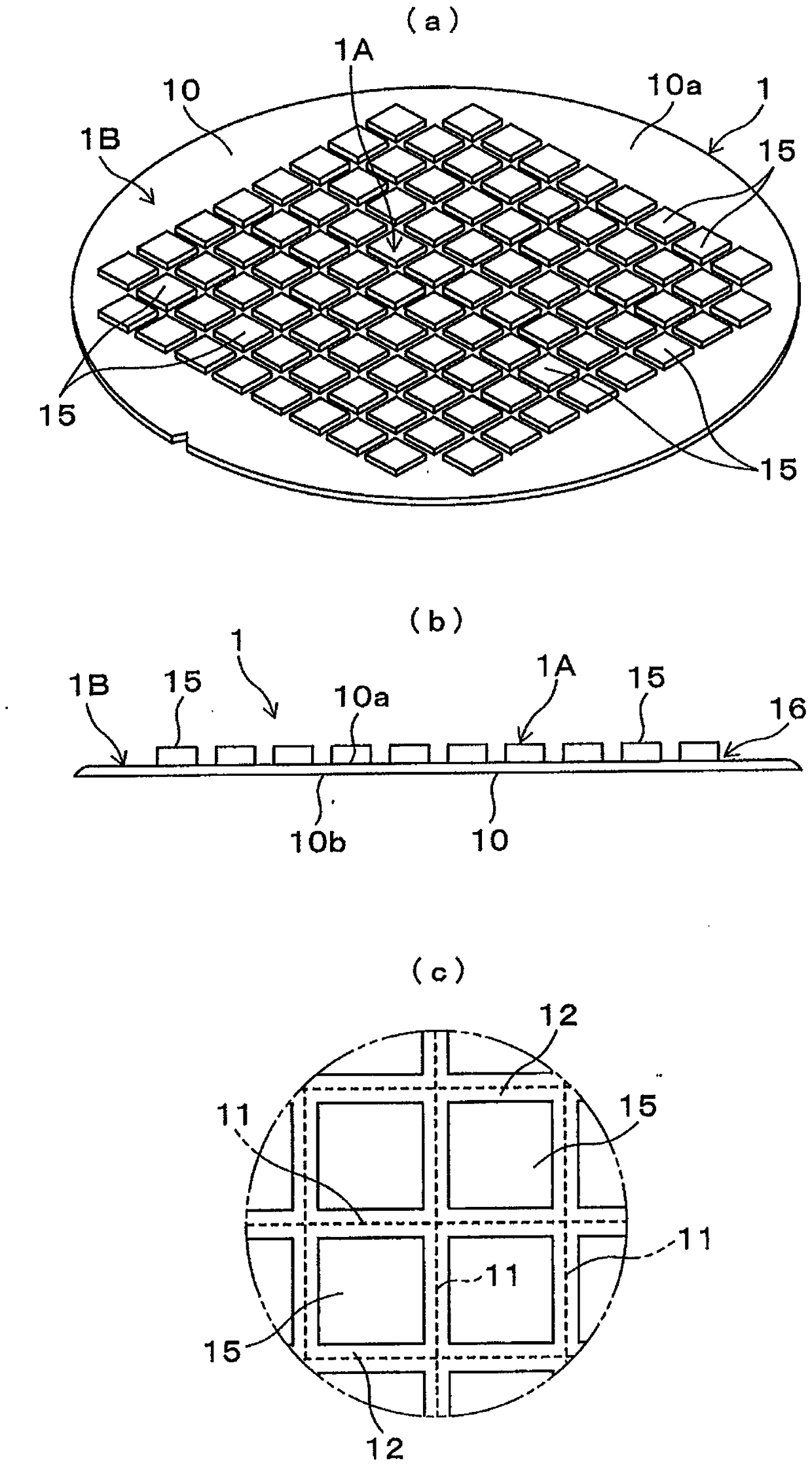

[0042] [1] Laminated wafer

[0043] figure 1 In one embodiment, a laminated wafer 1 divided into individual laminated chips is shown. The laminated wafer 1 has a plurality of rectangular chips 15 stacked on the surface 10a of a disk-shaped interposer wafer (hereinafter simply referred to as a wafer) 10 in which wiring, electrodes, etc. are incorporated. Chip 15 is a semiconductor device, etc., such as figure 1 As shown in (c), each chip 15 is stacked on each rectangular region 12 divided on the surface 10 a of the wafer 10 by grid-like dividing lines 11 . The wafer 10 is ground in advance on the back surface 10b side, and thinned to a predetermined thickness.

[0044]The laminated wafer 1 is divided into a substantially rectangular chip region 1A in which a plurality of chips 15 are laminated, and an outer peripheral remaining region 1B in which the outer peripheral portions of the chips 15 are not laminated. The thickness of the chip 15 is, for example, about 100 μm, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com