Method for forming perpendicular brittle material substrate and brittle material substrate dividing method

A technology for brittle material substrates and vertical cracks, applied in glass cutting devices, stone processing tools, stone processing equipment, etc., can solve the problem of partial extension of vertical cracks and achieve reliable segmentation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]

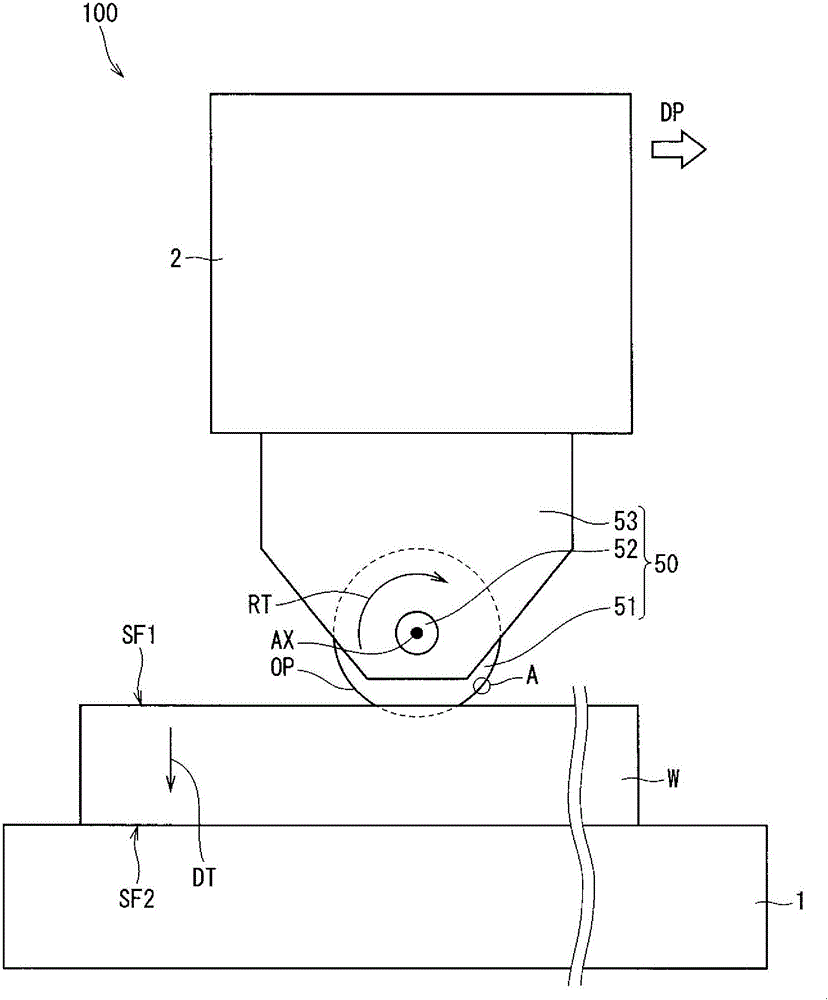

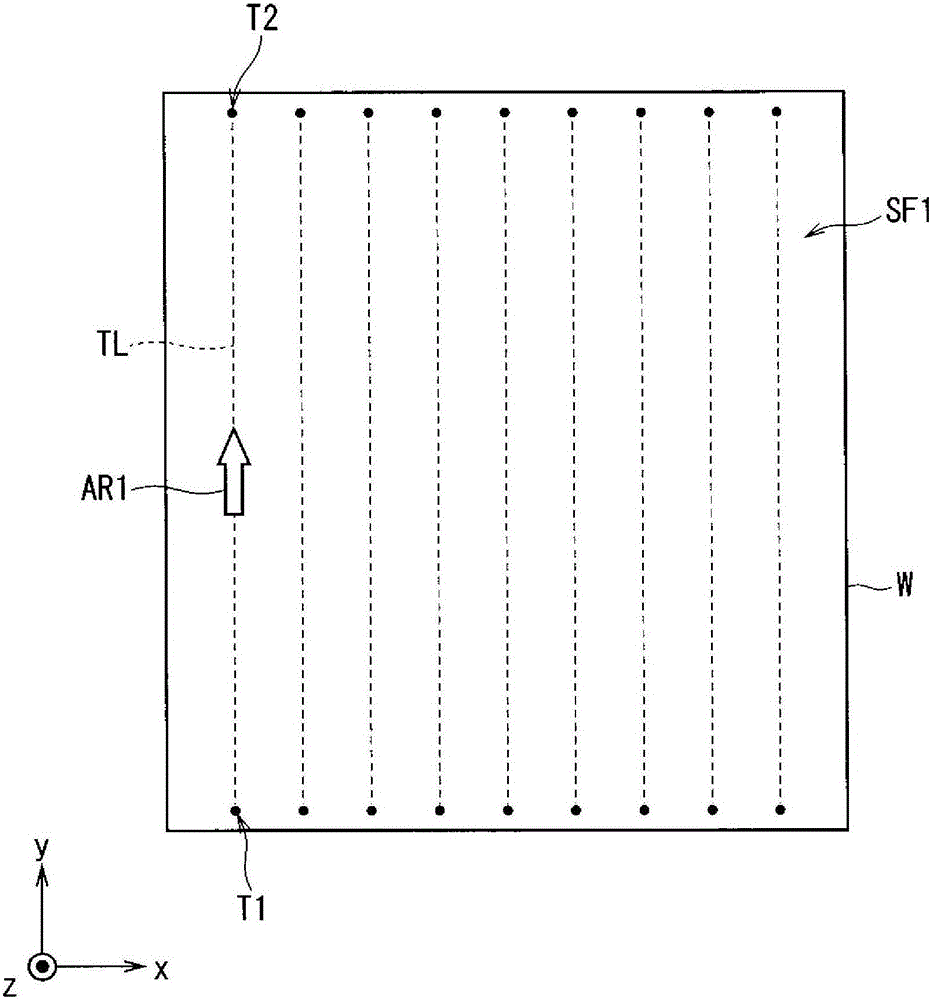

[0038] figure 1 It is a diagram schematically showing the configuration of the scribing device 100 used in the embodiment of the present invention. The scribing device 100 is generally used when dividing a brittle material substrate W such as a glass substrate, a ceramic substrate, or a semiconductor substrate at a predetermined dividing position in the thickness direction DT for downsizing, but in this embodiment, the scribing The apparatus 100 is to extend the vertical crack at the dividing position on the one main surface SF1 side of the brittle material substrate W, and the auxiliary line AL( Figure 6 etc. used for the formation of reference). In addition, in the present embodiment, the auxiliary line AL refers to the groove line TL formed at the division position on the side of the main surface SF1 (refer to image 3 etc.) are formed at the intersection position, and the vertical crack extends directly below the groove line TL as the starting point (trigger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com