Fatigue analysis method based on magnesium alloy test piece surface temperature characteristics

A surface temperature and fatigue analysis technology, which is applied in the direction of analyzing materials, strength characteristics, and preparation of test samples, can solve the problems that the specific characteristics of the magnesium alloy test piece are not accurately given, the test process is not simple enough, etc., and the test period is short. , save test time, the effect of less test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with specific embodiments.

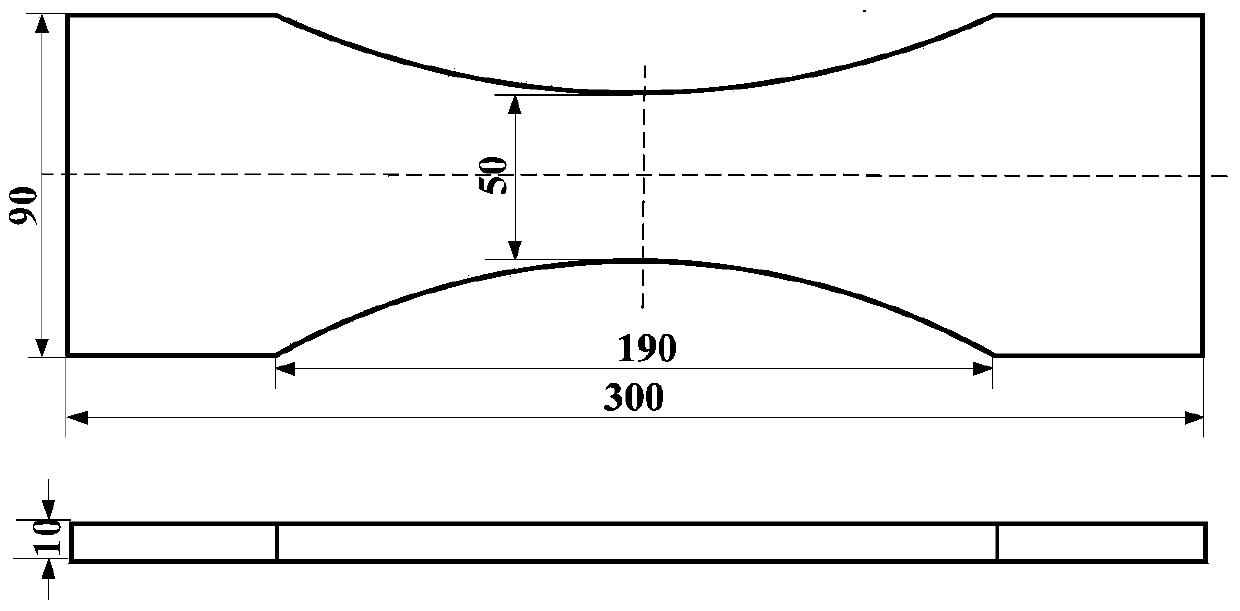

[0040]The material that the present invention adopts is the AZ31B magnesium alloy of commercial 10mm thick extrusion molding, and test piece size is as follows figure 1 As shown, the wire cutting method is used to process along the direction perpendicular to the extrusion; after the processing is completed, the surface of the test piece is polished with 800 mesh, 1000 mesh and 1500 mesh metallographic sandpaper in order to make the surface and the wire cutting surface smooth. The roughness reaches Ra0.32-0.63 μm; the surface of the test piece is coated with a layer of black matte paint to increase the heat reflectivity.

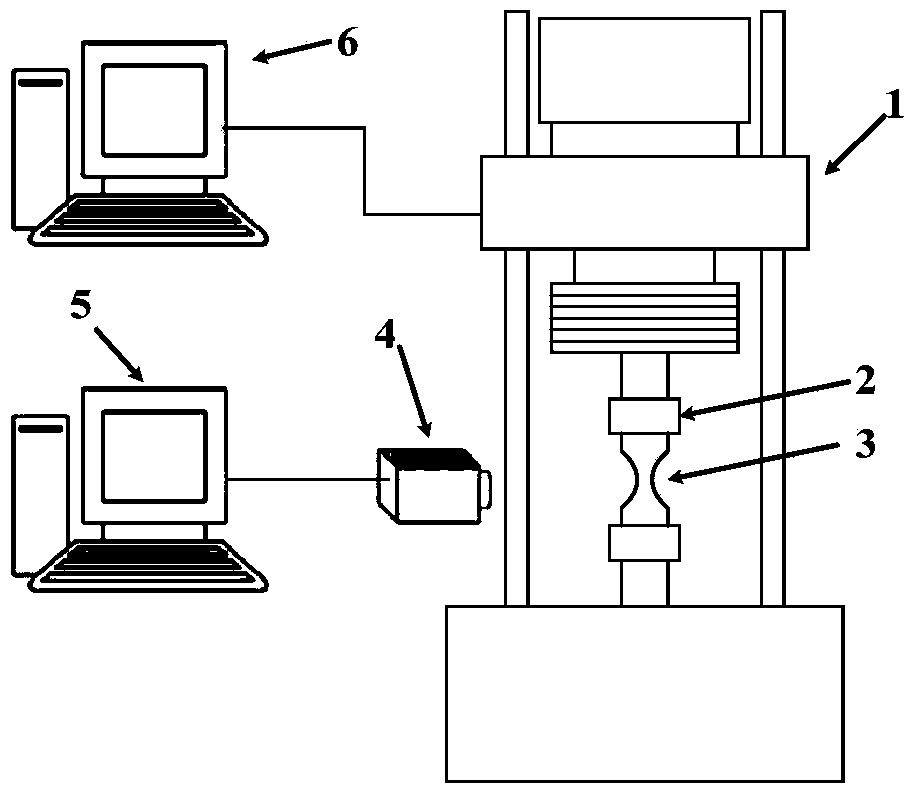

[0041] The fatigue test equipment is a high-frequency tension and compression fatigue testing machine. The fatigue load is a pull-pull load, the cycle characteristic coefficient is 0.1, and the vibration frequency is 100 Hz; during the experiment, the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com