Method and apparatus for displacement type pressure conveying of low-temperature liquefied gas

A low-temperature liquefied gas and pressure technology, applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve problems such as high maintenance costs, low boosting efficiency, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

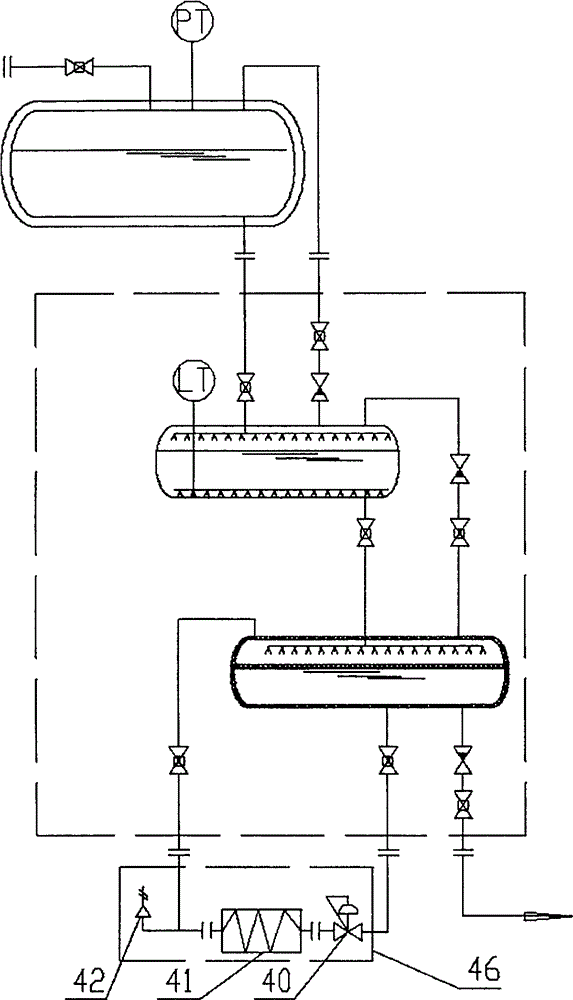

[0067] Embodiment 1: as figure 1 As shown, the displacement pressure conveying equipment for low-temperature liquefied gas includes a displacement unit (44), a BO6 processing unit (45), and a low-temperature liquid storage tank (24). The low-temperature liquid storage tank (24) is used for storing low-temperature liquefied gas, and may be a low-temperature storage tank, a low-temperature tank car, or a low-temperature gas cylinder. The cryogenic liquid storage tank (24) is provided with a liquid phase port at least at the lowest part of the liquid phase, and a gas phase port, a BOG valve (26) port, and a low temperature liquid storage tank pressure display sensor (25) at the highest gas phase.

[0068] The replacement unit (44) includes a heat absorption tank (16) and a replacement tank (14). When the gas phase pressure of the tank is equal, the low-temperature liquid in the low-temperature liquid storage tank (24) can enter the heat-absorbing tank (16) under the action of gr...

Embodiment 2

[0076] Embodiment 2: as figure 2 As shown, the self-pressurization unit (46) includes a self-supporting booster regulating valve (40), a booster gasifier (41) connected in sequence, and a gasifier safety valve (42) is provided on the communication pipeline.

[0077] The boost gasifier (41) is connected to the boost port (3); the self-supporting boost regulating valve (40) is connected to the boost liquid outlet (2).

[0078] When the self-pressurizing unit (46) is installed, the highest point should be lower than the lowest point of the displacement tank (14), and the ventilation should be good. It is beneficial that the low-temperature liquefied gas in the displacement tank (14) at a high place can enter the self-pressurization unit for gasification and pressurization under the action of its own weight. The self-supporting booster regulating valve (40) is an automatic pressure regulating valve, when the pressure in the displacement tank (14) is lower than the set pressure o...

Embodiment 3

[0080] Example 3 as image 3 As shown, the replacement units (44) and the corresponding self-pressurizing units (46) can be used in parallel, and the work process of each basic replacement unit is alternately carried out at the same time by controlling (that is: there are One replacement unit (44) performs liquid filling process, one replacement unit (44) performs heat absorption and pressure reduction process, one replacement unit (44) performs gas-liquid replacement process, and one replacement unit (44) performs liquid discharge process) , to ensure that one of them performs the liquid discharge process at any time, which can realize the uninterrupted delivery of low-temperature liquefied gas to the outside.

[0081] Others are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com