Hydrostataktor

A hydrostatic and actuator technology, applied in the direction of electric clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of extending the axial installation space and achieve the effect of small installation space and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

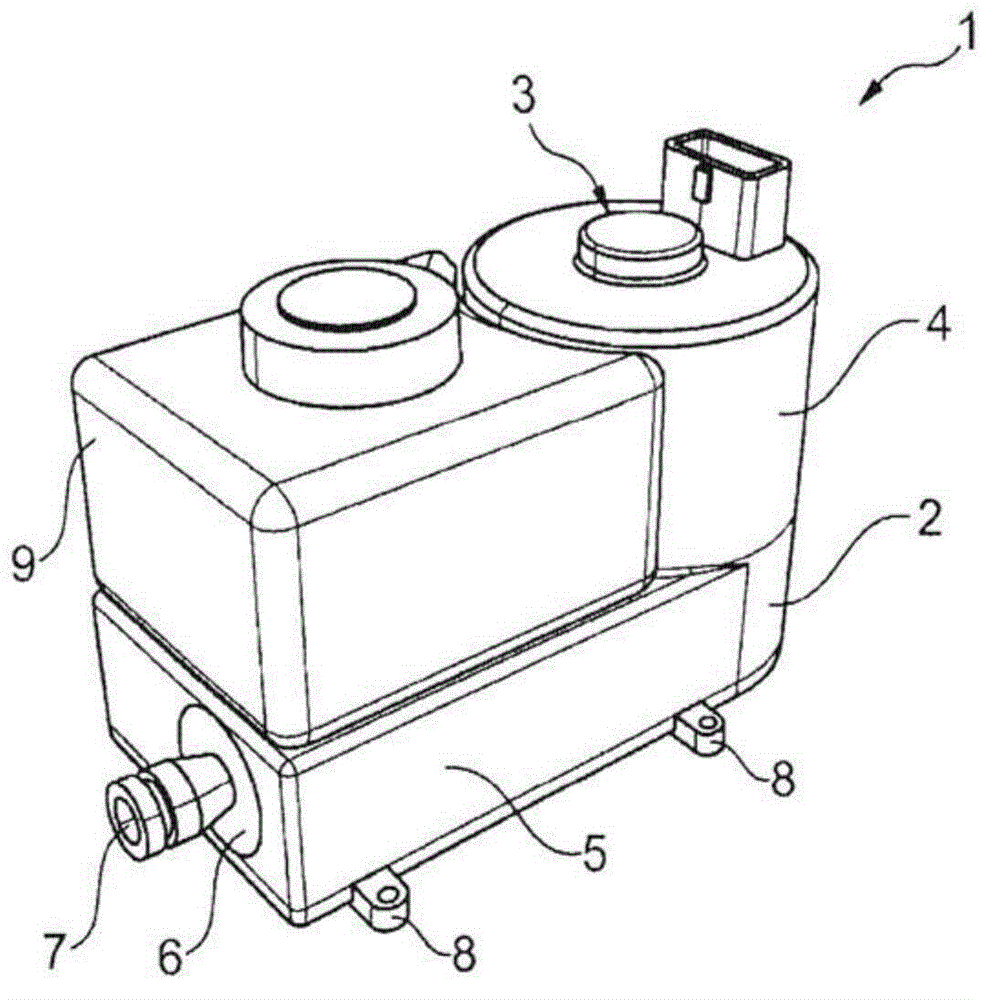

[0014] figure 1 The hydrostatic actuator 1 is shown in 3D. The schematic illustration shows a housing 2 which receives an electric motor 3 on a circular housing part 4 in a vertical orientation. For this purpose, the master cylinder 6 is arranged vertically in a horizontal orientation in the flat housing part 5 . On this flat housing part 5 a storage tank 9 is accommodated between the pressure connection 7 and the housing part 4 without increasing the vertical installation space of the hydrostatic actuator 1 . The hydrostatic actuator 1 is accommodated in the chassis of the motor vehicle or on the motor housing or transmission housing by means of the fastening web 8 .

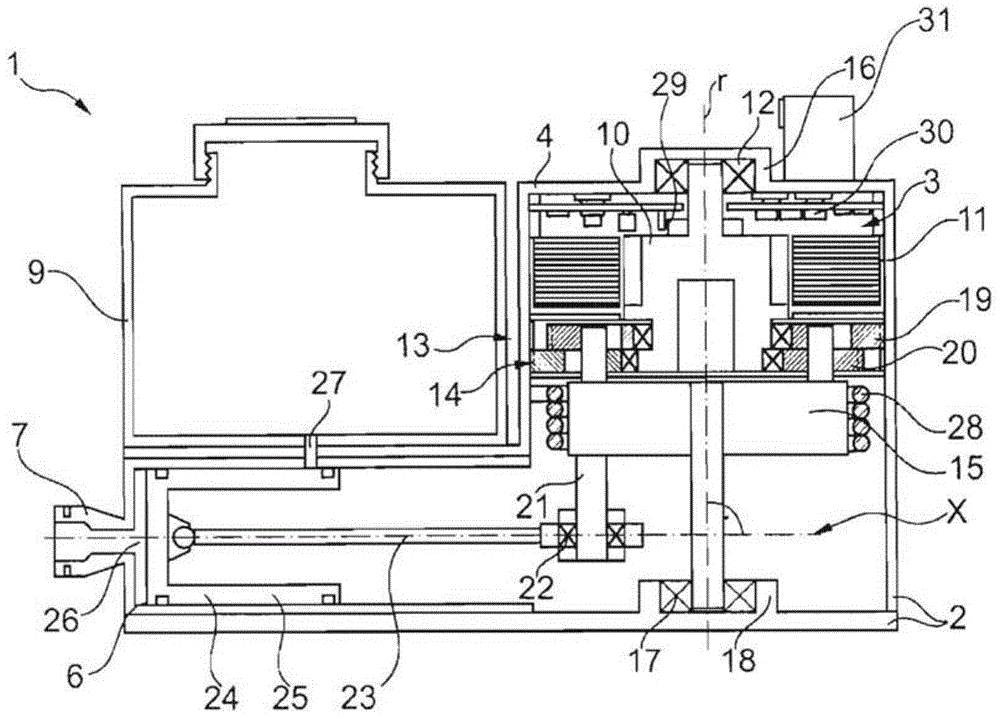

[0015] figure 2 show figure 1 A longitudinal section of the hydrostatic actuator 1 along the rotor axis r of the rotor 10 of the electric motor 3 and the longitudinal axis x of the master cylinder 6 . The rotor axis r and the longitudinal axis x are arranged substantially at right angles, so that the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com