Replacing device of self-elevating type platform truss spud leg semicircular plate and replacing method thereof

A self-elevating platform and equipment replacement technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of platform use, high cost, long construction period, etc., to control uncontrollable deformation, Ensure the quality of repairs and the balance of the force on the legs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

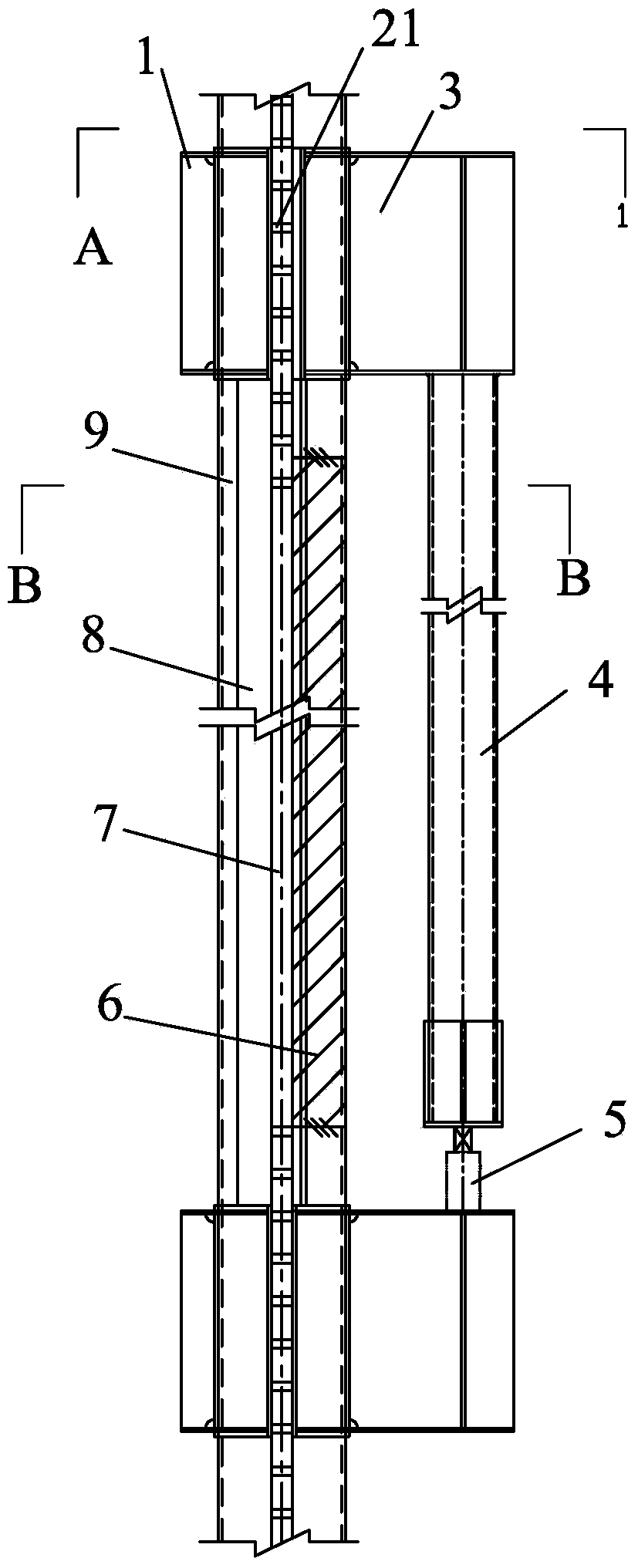

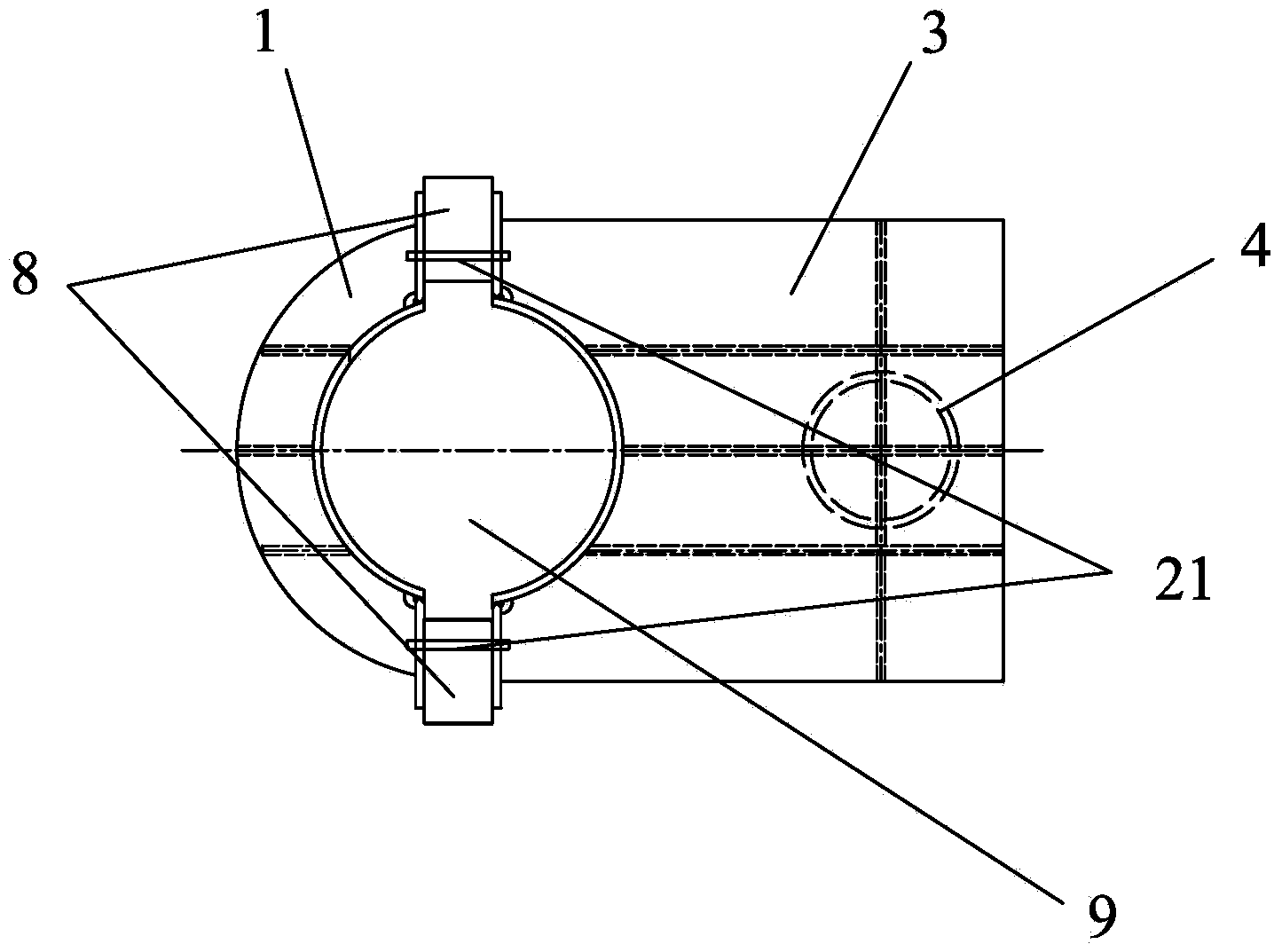

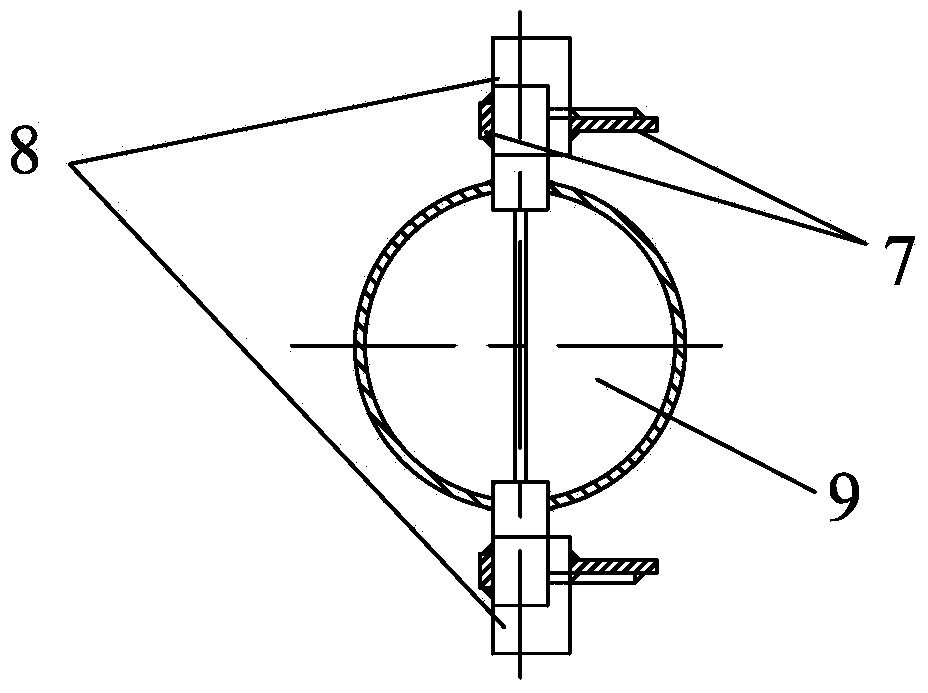

[0025] The self-elevating platform pile leg semi-circular plate replacement tooling of the present invention is used for the tooling equipment when the self-elevating platform leg semi-circular plate is replaced, including the outer sheath support seat tooling and the inner sheath tooling set on the self-elevating platform leg, The tooling of the outer sheath support seat and the inner sheath tooling are connected as a whole by bolts 21, so that a tooling base that does not affect the original leg structure is formed on the pile leg. The tooling base is installed at the upper and lower ends of the semicircular plate replacement area, and then a supporting steel pipe and a vertical jack are set between the upper and lower sides to support the main chord of the pile leg and provide pre-tightening force. At the same time, through the tool base, the tooth-shaped complementary plate and the anti-bending back plate are installed on the main chord tube of the pile leg.

[0026] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com