Improvement method for preventing clogging of hard loading pipes of shield machine

A technology of shield machine and hard pipe, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., to achieve the effects of improving safety and reliability, reducing construction waste, and reducing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention is an improved method for preventing the hard feeding pipe of a shield machine from being blocked, and the improved method of the invention can effectively solve the problems existing in the background technology.

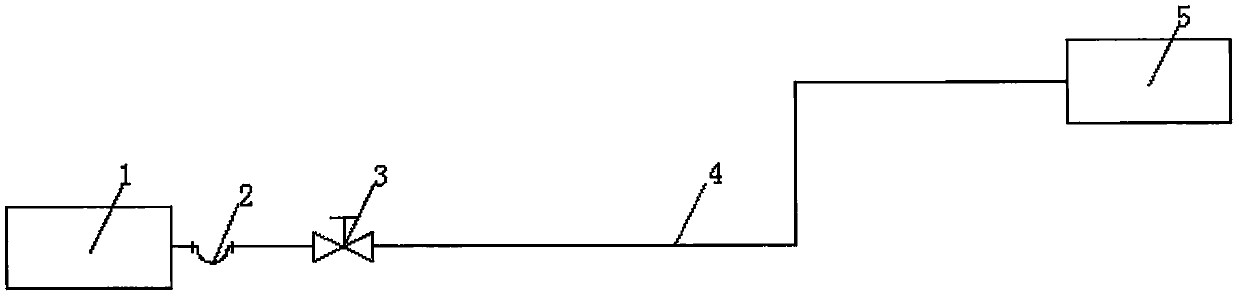

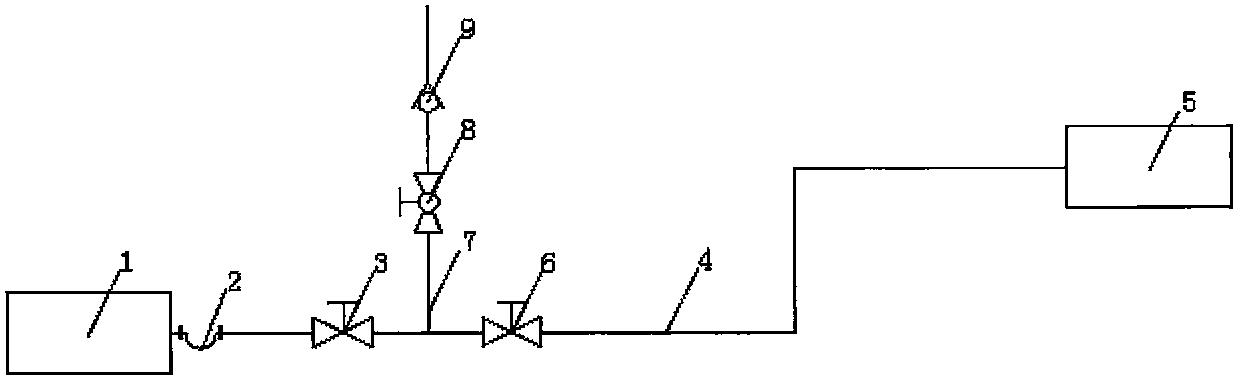

[0019] The present invention adds a second manual feeding plate valve 6, an air inlet pipe 7, a manual air inlet ball valve 8 and an air inlet check valve 9 on the basis of the original shield machine feeding system. The original feeding system includes a mortar tank car 1, The feeding hose 2, the first manual feeding board valve 3, the feeding hard pipe 4 and the slurry storage tank 5.

[0020] For the connection relationship formed by the original feeding system and the above-mentioned components newly added in the present invention, please refer to the technical solution, and no further description will be given.

[0021] The method that the present invention solves the blockage of feeding hard pipe is as follows:

[0022] 1. When the morta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com