Protective mesh for manual hole-digging piles

A technology of manual digging piles and protective nets, which is applied in the fields of construction, building structure, and building materials, can solve the problems of easy damage of protection, non-reusable protection, and inadequate protection, so as to reduce engineering costs, High construction efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The protective net for manual digging piles of the present invention comprises a reinforcement ring and a protective cover.

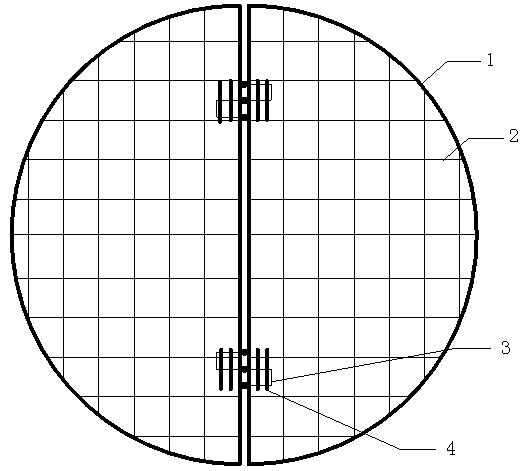

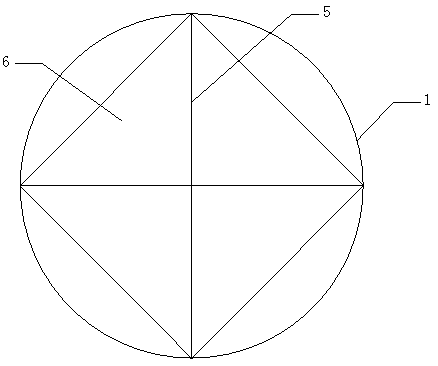

[0028] see now figure 1 , figure 1 It is a structural schematic diagram of a reinforcement ring according to an embodiment of the present invention. As shown in the figure, the radius of the reinforcement ring is 200mm larger than that of the manual digging pile, and the reinforcement ring is set as two symmetrical semicircular reinforcement rings. To connect, set reinforcing ribs on the reinforcement mesh at the junction of the two semicircular reinforcing bars, and weld the hinges on the reinforcing ribs so that the two semicircular reinforcing bars can be folded with each other. The steel bars of the semicircular steel ring are steel bars with a diameter of 20mm. The steel bars of the steel mesh sheets are steel bars with a diameter of 18mm. The hinge is a casement hinge 3, and the casement hinge is made of stainless steel, with a central ...

Embodiment 2

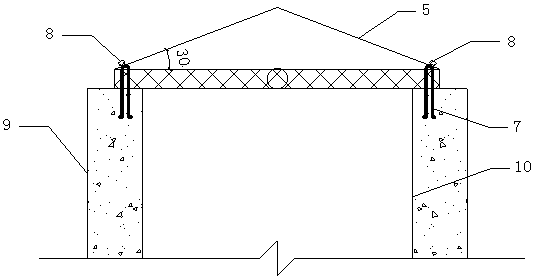

[0032] image 3 It is a schematic diagram of the use state of the protective net according to the embodiment of the present invention. The method of using the manual hole-digging pile protective net of the present invention: during construction, open the lock at one end of the foldable protective net, turn up the protective net at the end and fold it on the protective net at the locked end, and the construction personnel can stand Laying bamboo plywood on the folded protective mesh can ensure the safety of workers on the manual digging piles, and can also greatly reduce the risk of workers under the manual digging piles being hit by falling objects. After the construction of the manual hole-digging pile is completed, the two protective mesh sheets are unfolded to form a foldable protective mesh sheet, and then the foldable protective mesh sheet is laid on the artificial hole-digging pile, and the two ends of the foldable protective mesh sheet are passed through Pre-buried on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com