Car roof composite electronic fabric, fullerene polymer and preparation method of fullerene polymer

A fullerene and polymer technology, applied in the field of auto parts, can solve the problems of small effective area and affect the overall appearance of the interior environment of the car, and achieve the effect of increasing generation efficiency and improving release efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

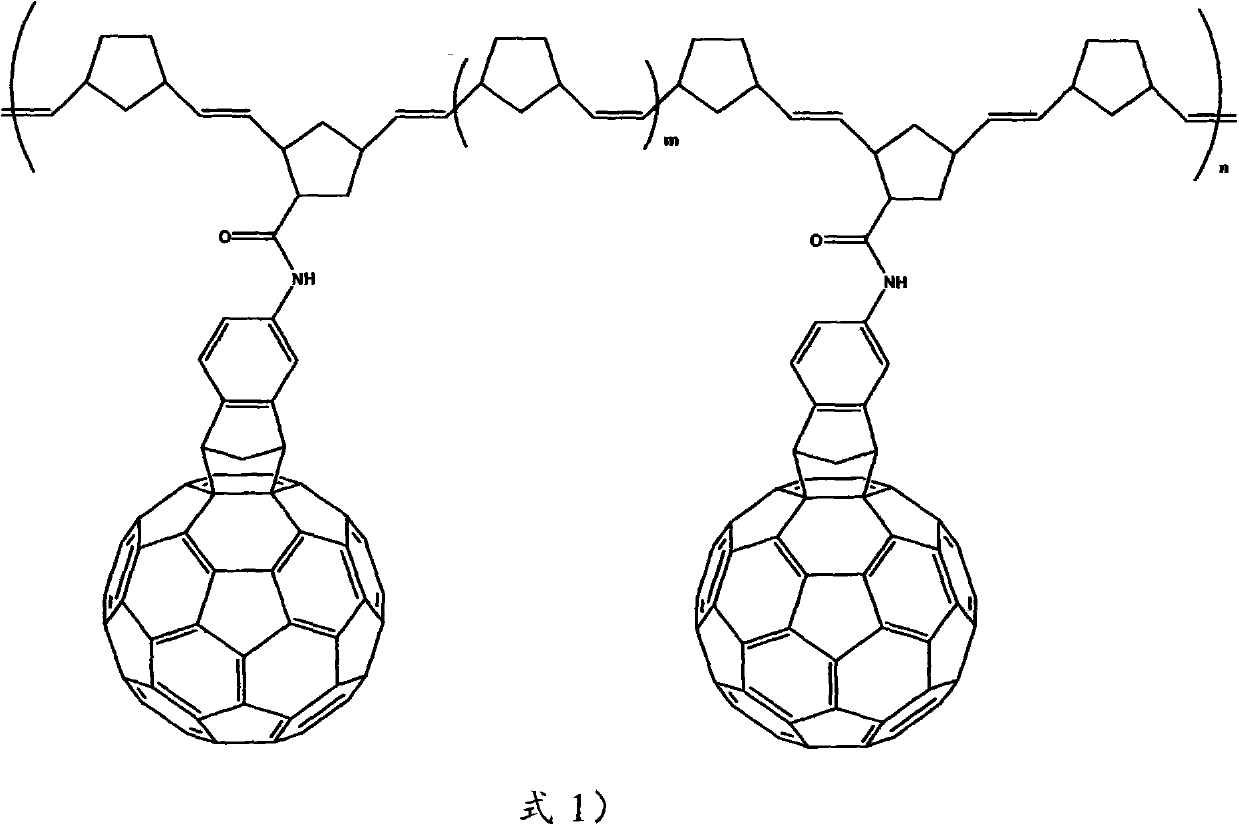

[0033] Specifically, the preparation method of the fullerene polymer comprises the following steps: mixing N-(5-indenyl)-5-norbornene-2-carboxamide and C in a molar ratio of 5 to 10:1 60 Dissolve in 1,2,4-trichlorobenzene, heat and reflux for 12 to 13 hours, then pour into methanol to precipitate, filter with suction and wash the precipitate with methanol to obtain a reaction crude product, dissolve the reaction crude product in toluene, and use Adsorbed on silica gel, and then separated and purified with toluene and n-hexane with a volume ratio of 1:9 as the eluent to obtain a fullerene macromonomer, the 1,2,4-trichlorobenzene and C 60 The volume-to-mass ratio is 40-50mL / 1g, and the heating and reflux temperature is greater than 214°C; the fullerene macromonomer and norbornene are dissolved in toluene, Grubbs catalyst is added, and the reaction is carried out at room temperature for 2 hours. Vinyl ether is added to terminate the reaction, and then ether is used for precipitat...

Embodiment 1

[0045] Synthesis of Fullerene Macromers

[0046] First, dissolve the solid mixture of 0.74g sodium borohydride and 1.87g precipitated sulfur in 50mL dry tetrahydrofuran to obtain sodium thioborohydride solution, then add 5-nitroindene solution in tetrahydrofuran (1g / 5mL) to keep the reaction The mixture was stirred at room temperature for 16 hours.

[0047] Water was then slowly added to the reaction system, and the reaction liquid was extracted three times with 10 mL of ether, and the organic phases were combined, and the organic phases were washed with 10 mL of distilled water and 10 mL of saturated brine.

[0048] The unstable 5-aminoindene was not isolated, but a freshly prepared 5 mL solution of 5-norbornene-2-formyl chloride in dichloromethane (1.17 g of 5-norbornene-2-carboxylic acid in 6 mL of oxalyl chloride was refluxed 5h, rotary evaporation to remove oxalyl chloride) was directly dropped into the solution of 5-aminoindene, and then 1.1 mL of acid-binding agent tri...

Embodiment 2

[0054] Synthesis of fullerene polymers

[0055] Dissolve 0.97g of the fullerene macromonomer prepared in Example 1 and 9.41g of norbornene in 20mL of toluene, add a catalytic amount of Grubbs catalyst, react at room temperature for 2h, add vinyl ether to terminate the reaction, and then carry out the reaction with ether Precipitate to obtain 10.01 g of a purple-black solid, with a yield of 96.4%, that is, a novel polymer with fullerene functional groups hanging on the side chain, GPC=32.5kD, M ‾ w / M ‾ n = 1.21 .

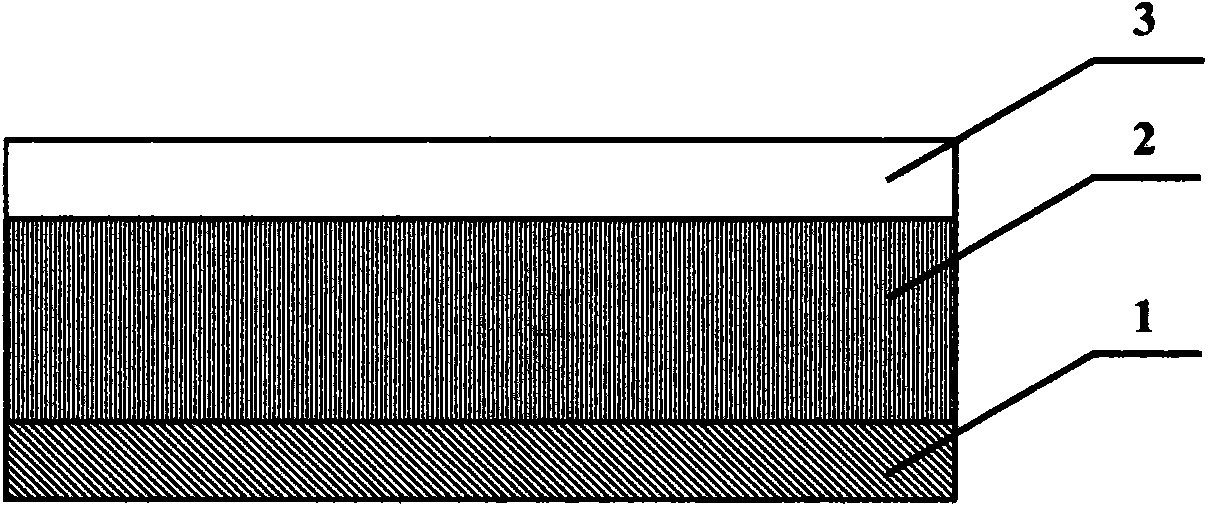

[0056] Among them, the 1st and 2nd layers are bonded with waterproof magic stickers, and the 2nd and 3rd layers are bonded with waterproof glue.

[0057] The waterproof glue was purchased from Shanghai Suao Chemical Co., Ltd., model SA-1002.

[0058] The amount of waterproof glue is calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com