Grinding machine

A grinding machine and station technology, which is applied in the field of grinding machines, can solve the problems of reduced work efficiency and worker efficiency, and achieve the effects of improving work efficiency, reducing placement time and processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

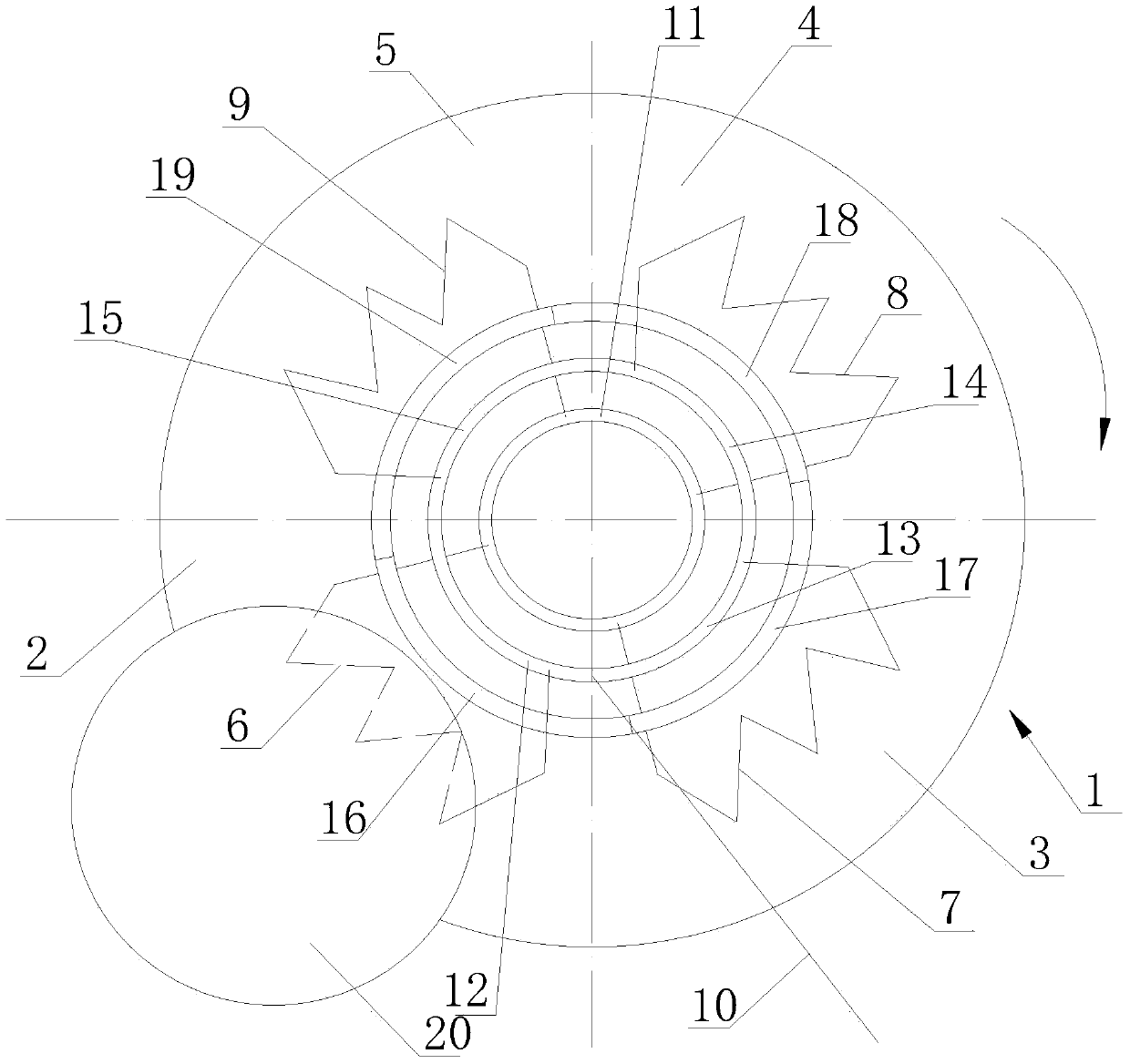

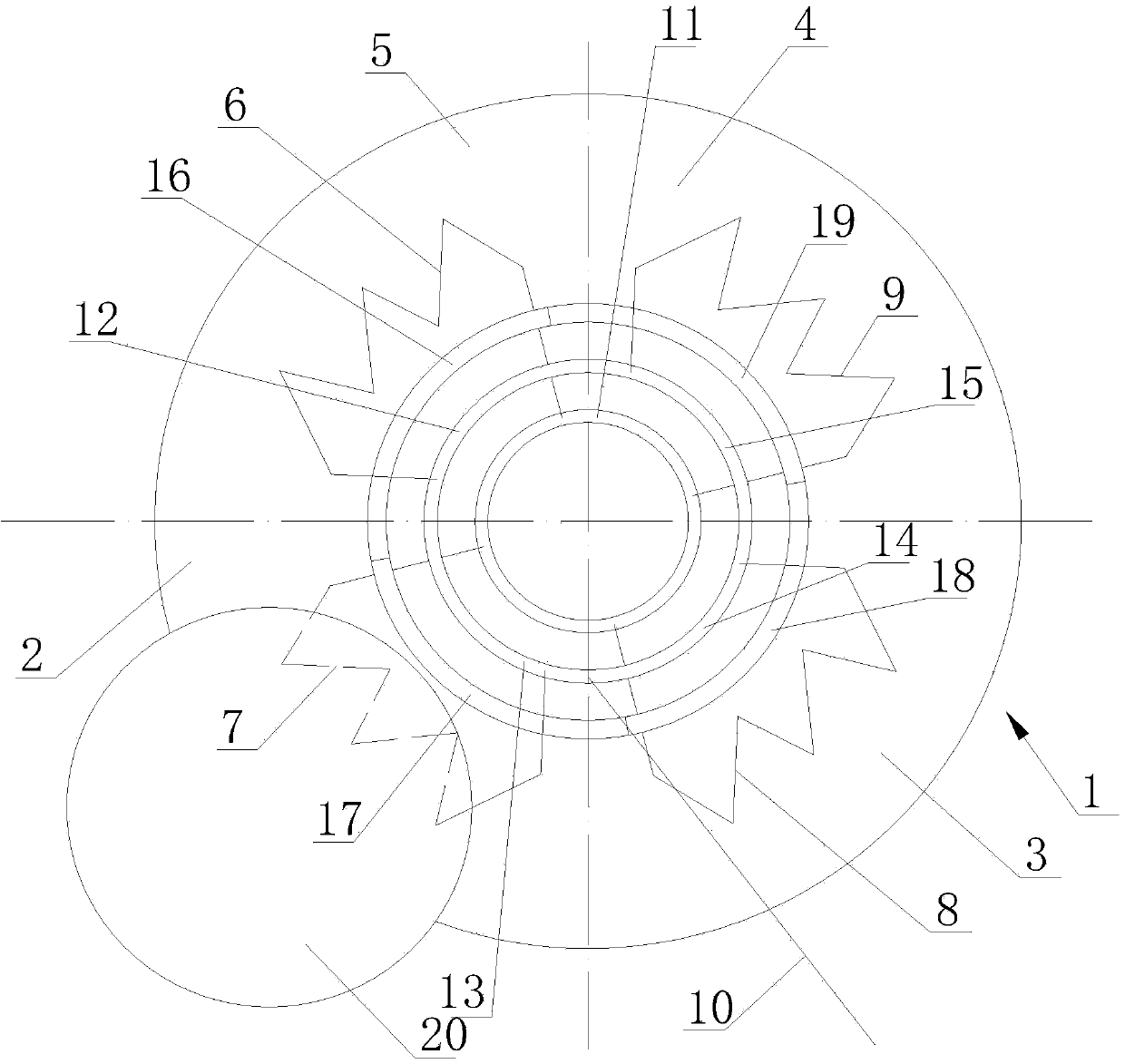

[0014] Such as figure 1 As shown, the grinding machine of the present invention includes a self-rotating suction cup 1 and a grinding wheel 20 arranged above the suction cup, and the suction cup is provided with a working station 2, a preliminary station 3 and at least one loading and unloading station. Two loading and unloading stations are adopted in the machine, that is, loading station 4 and unloading station 5. If the workers are skilled, the loading station and the unloading station can be placed on one station during actual production, that is, the workers are working The metal parts on position 2 can be removed from the loading and unloading station within the time after the processing is completed, and then put on the metal parts to be processed. All the stations are evenly distributed on the suction cup 1, that is, the working statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com