Distillation tower used for hydrogen peroxide purification

A distillation tower and hydrogen peroxide technology, applied in the field of distillation towers, can solve problems affecting the quality and quality of hydrogen peroxide, and achieve the effects of avoiding excessive or underdosed use, increasing production capacity, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

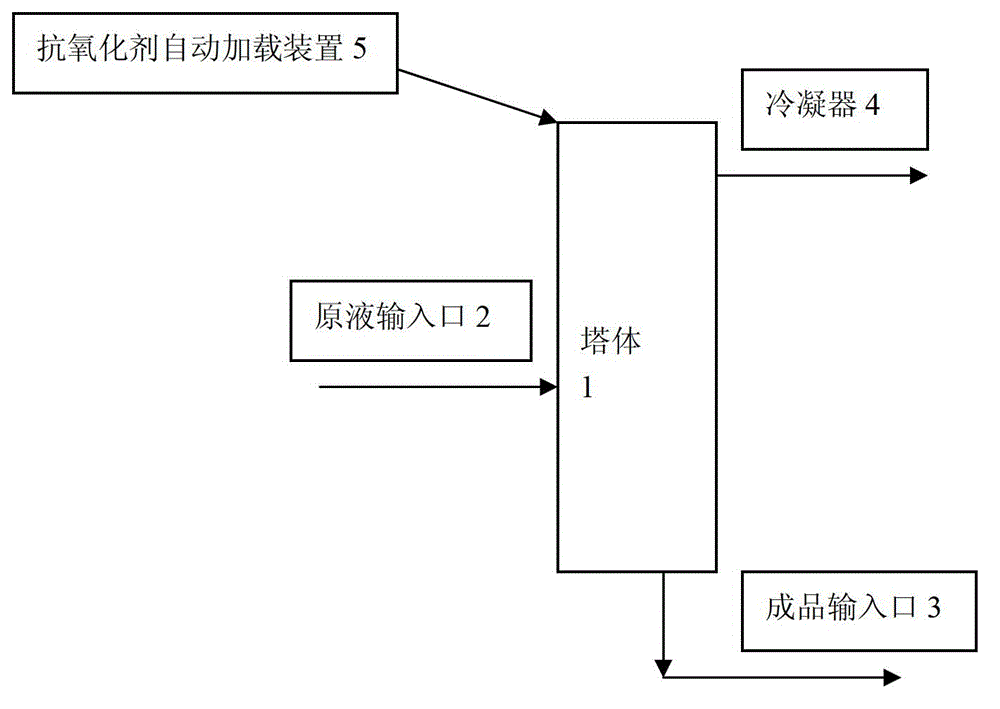

[0020] like figure 1 and 2 As shown, a distillation tower for hydrogen peroxide purification includes a tower body 1, a raw liquid input port 2, a condenser 4, a finished product output port 3, and an antioxidant automatic loading device 5 arranged at the top of the tower. The raw liquid input port 2. The condenser 4 and the finished product output port 3 are respectively connected to the tower body 1;

[0021] The antioxidant automatic loading device 5 automatically adds a corresponding amount of antioxidant into the tower body according to the liquid level of the raw liquid when the raw liquid is input into the raw liquid input port 2 .

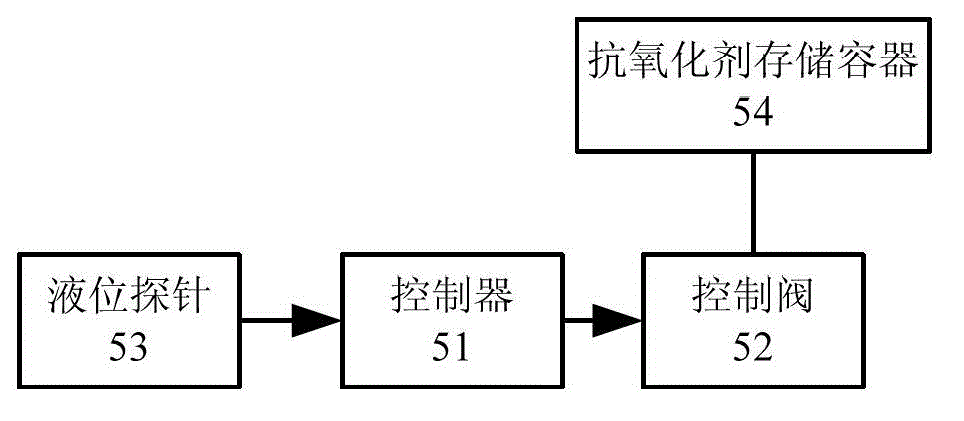

[0022] The antioxidant automatic loading device 5 includes an antioxidant storage container 54, a control valve 52, a controller 51 and a liquid level probe 53. The control valve 52 is located at the output port of the antioxidant storage container 54, and the The controller 51 is respectively connected with the control valve 52 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com