Protection method of quartz tube

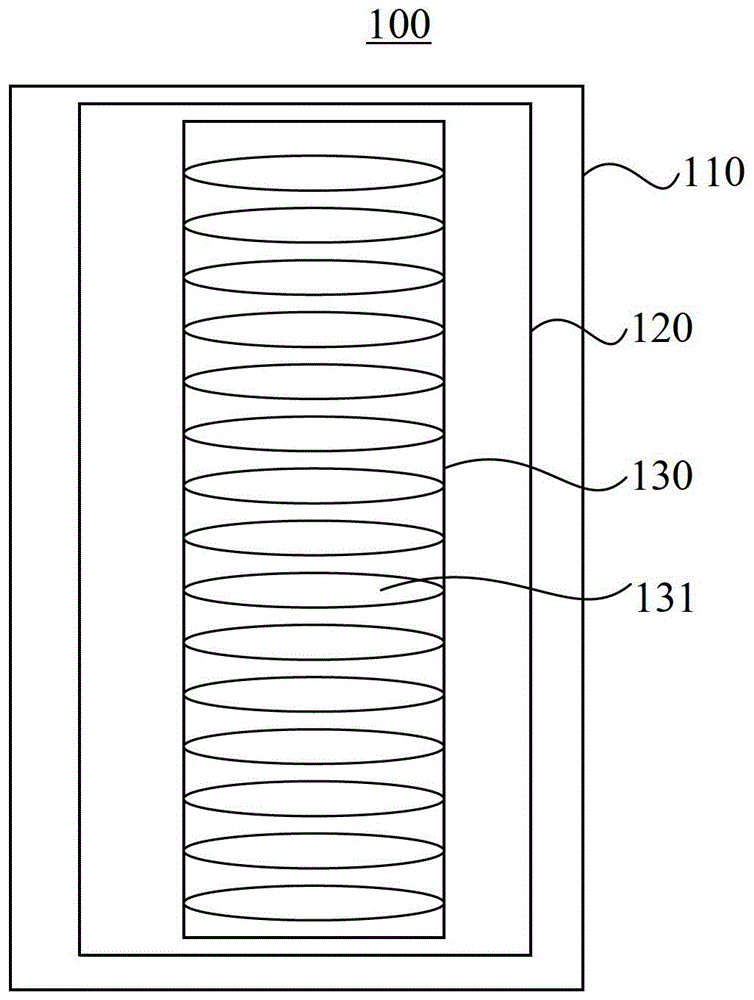

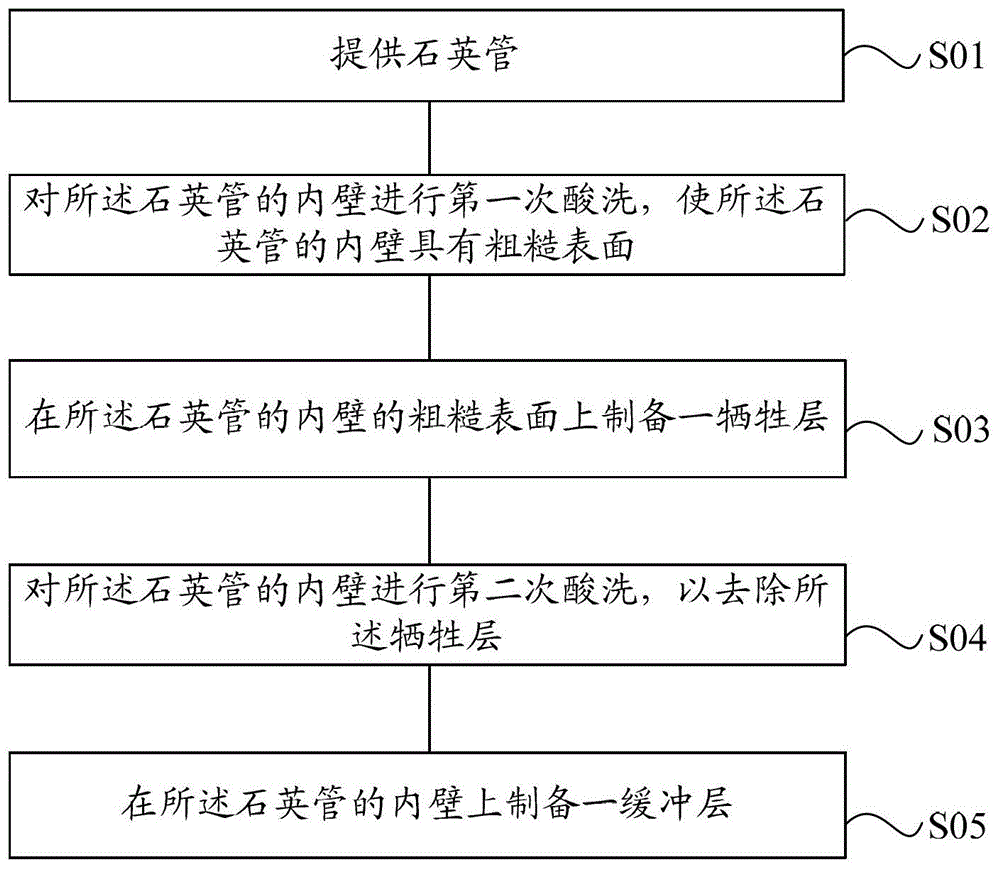

A quartz tube and sacrificial layer technology, applied in chemical instruments and methods, gaseous chemical plating, crystal growth, etc., can solve the problem of increasing the peeling off of the quartz tube 110 polysilicon film, affecting the reliability of the low-pressure chemical vapor deposition process, and increasing the low-pressure chemical vapor deposition process. Problems such as deposition equipment, to achieve good stretchability and porosity, relieve stress release, and prevent particles from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the low-pressure chemical vapor deposition equipment of the prior art, when the process of low-pressure chemical vapor deposition is carried out, many stress stripes will appear on the inner wall of the quartz tube, and the deposited film will be deposited on the inner wall of the quartz tube. Existence causes the deposited film to peel off to form particles. After in-depth research on the existing low-pressure chemical vapor deposition equipment, the inventor found that the material of the wafer is silicon, and the material of the quartz tube is silicon oxide. However, the thermal expansion coefficient of silicon is 2.6×10 - 6 K -1 , the thermal expansion coefficient of silicon oxide is 0.5×10 -6 K -1 , due to the large difference in thermal expansion coefficient between silicon and silicon oxide, when the low-pressure chemical vapor deposition process is performed, the temperature in the low-pressure chemical vapor deposition equipment is the temperature suitabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com