High-uniformity GaN film growing on sapphire substrate and preparing method and application of high-uniformity GaN film

A sapphire substrate, uniform technology, used in climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of high cost, difficulty in preparing high uniformity GaN thin films, and low LED luminous efficiency and other problems, to achieve the effect of improving utilization, repeatability, and unique growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

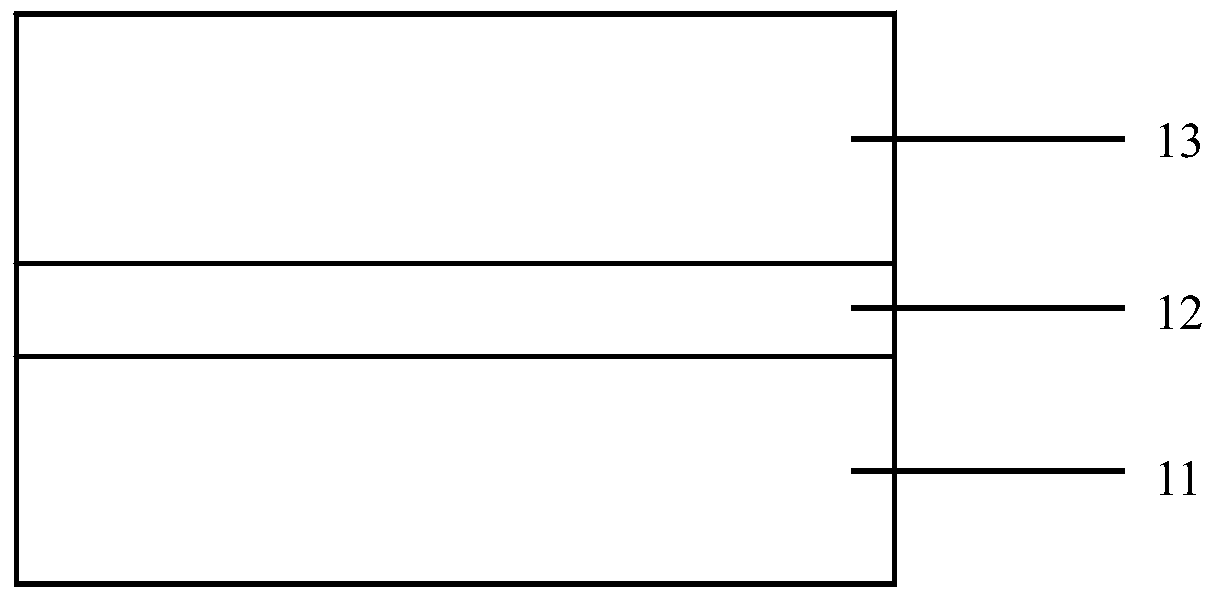

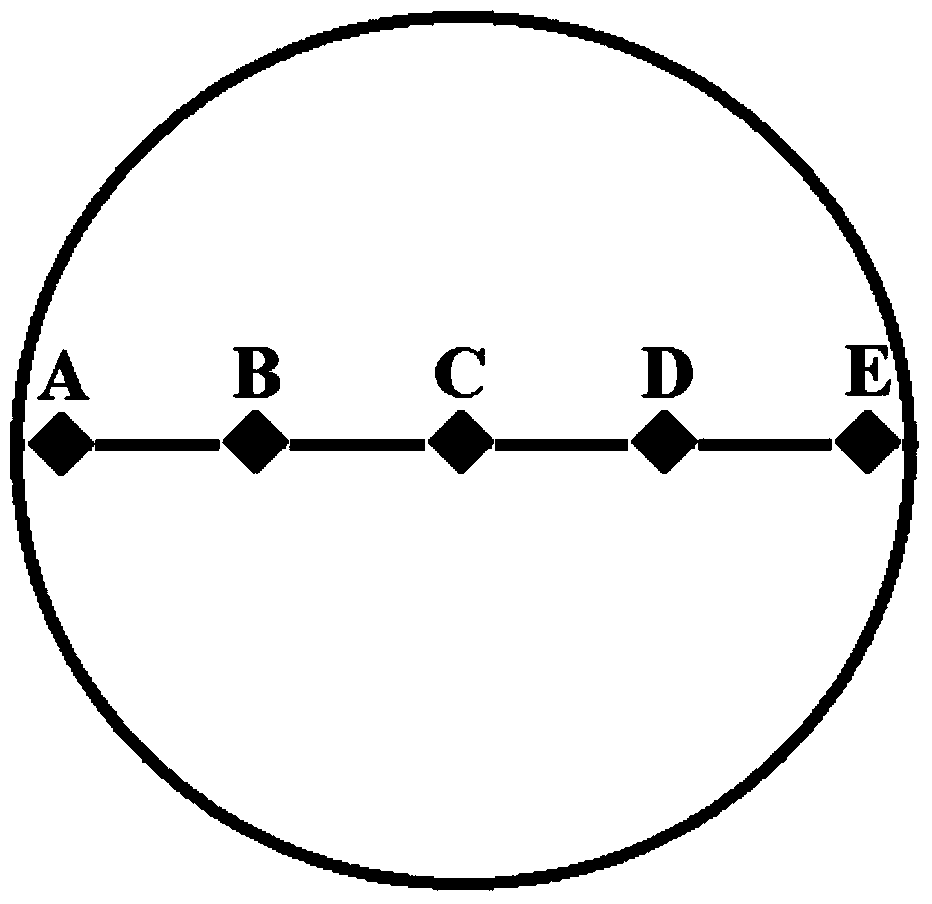

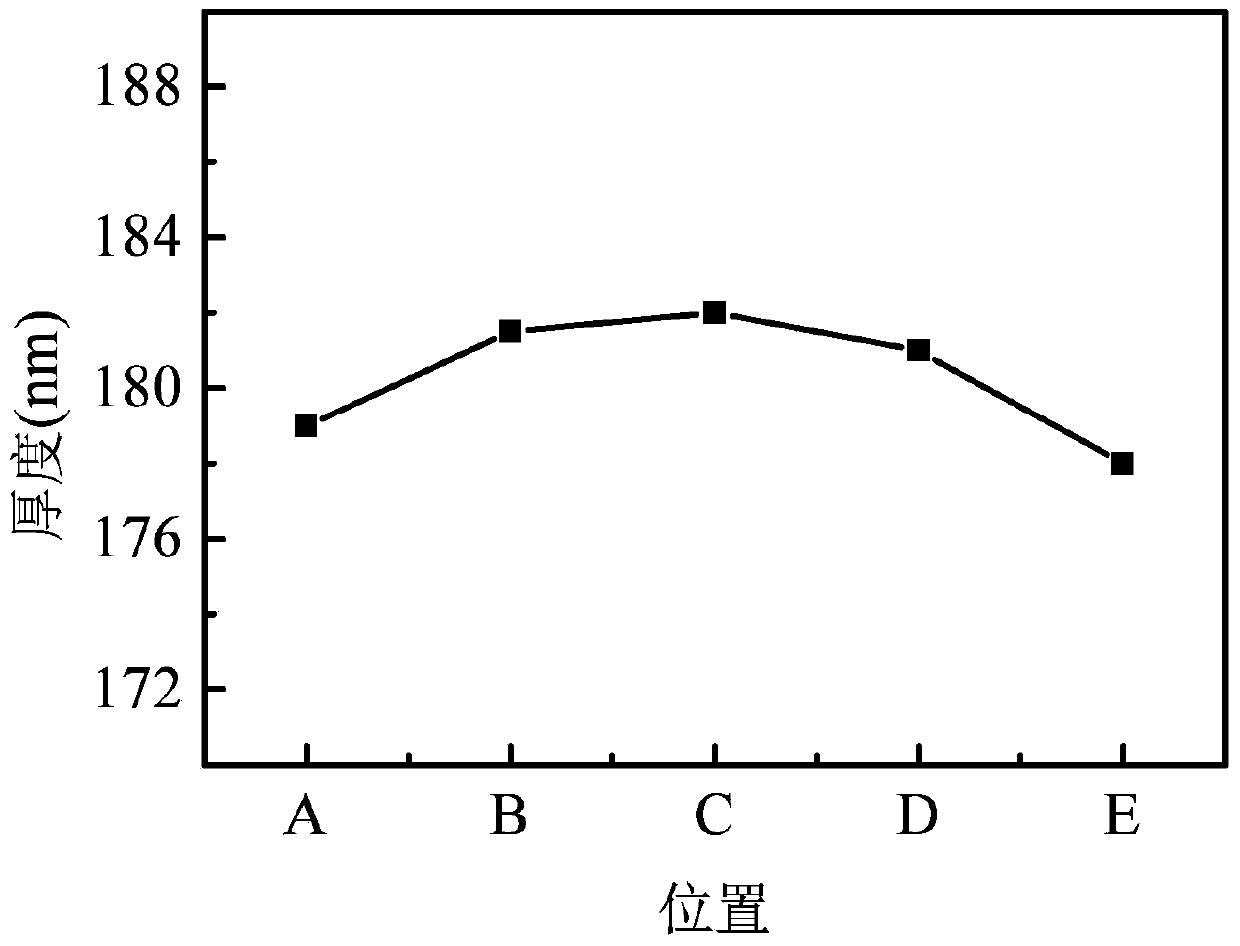

[0031] Combine Figure 1-3 . A GaN film grown on a sapphire substrate (see attached figure 1 ), including growing in Al 2 O 3 The substrate (11) and its (0001) plane are offset from the (10-10) plane by 0.2° (the crystal epitaxial orientation relationship is: the (0001) plane of GaN is parallel to Al 2 O 3 (0001) plane) as the AlN nucleation layer (12) on the crystal epitaxial growth, and the GaN film (13) grown on the AlN nucleation layer (12). The thickness of the AlN nucleation layer (12) is 8 nm, the thickness of the GaN thin film (13) is 180 nm, and the unevenness is 2.20%.

[0032] The method for preparing a GaN film grown on a sapphire substrate of this embodiment is prepared by the following steps:

[0033] a. Al 2 O 3 The substrate is cleaned and annealed; the specific annealing process is: put the substrate into an annealing chamber, and treat Al in a nitrogen atmosphere at 850°C. 2 O 3 The substrate is annealed for 1 hour; the cleaning is specifically: Al 2 O 3 The subs...

Embodiment 2

[0044] This embodiment is performed on the basis of embodiment 1, and the difference is that: the thickness of the AlN nucleation layer (12) is 10 nm, the thickness of the GaN film (13) is 100 nm, and the unevenness is 2.94 %.

Embodiment 3

[0046] This embodiment is carried out on the basis of embodiment 1, and the difference is that the thickness of the AlN nucleation layer (12) is 5nm, the thickness of the GaN thin film (13) is 200nm, and the unevenness is 2.47 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com