A high-efficiency and energy-saving drum drying equipment

A drying and drying equipment, high-efficiency and energy-saving technology, applied in drying, dryer, non-progressive dryer and other directions, can solve the problems of unfavorable environmental protection and effective utilization of resources, low thermal efficiency, high energy consumption, etc., to eliminate Adverse effects, effect of preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

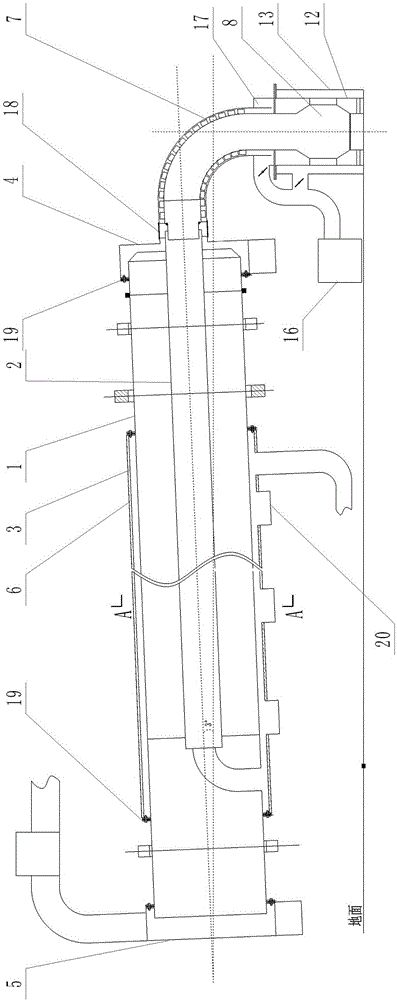

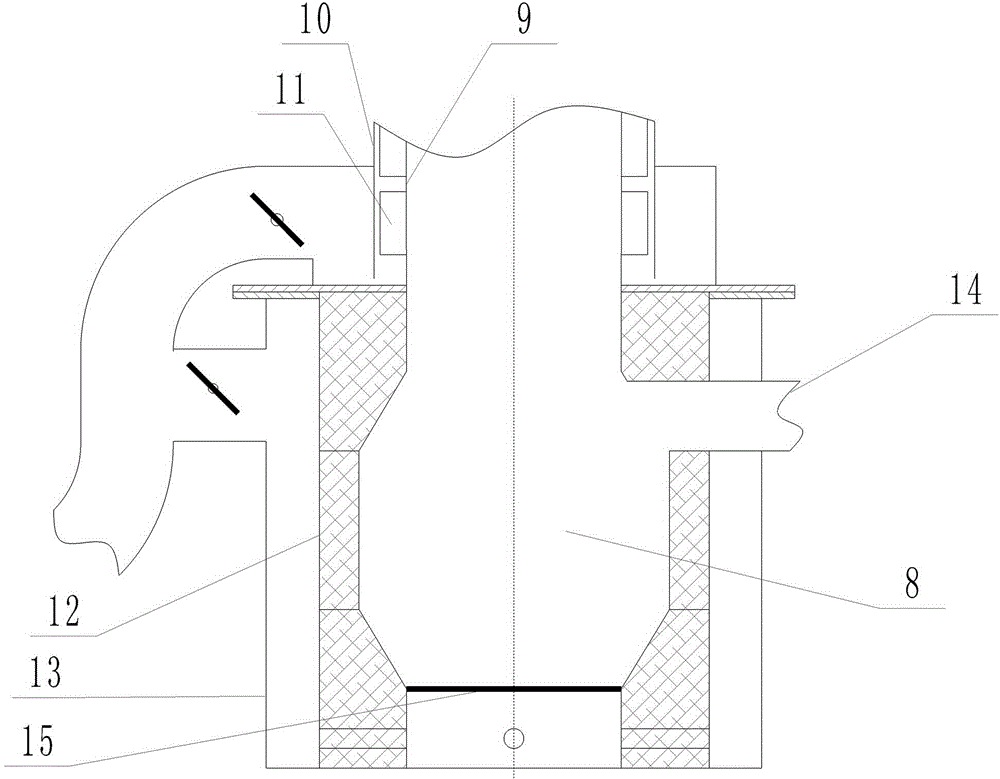

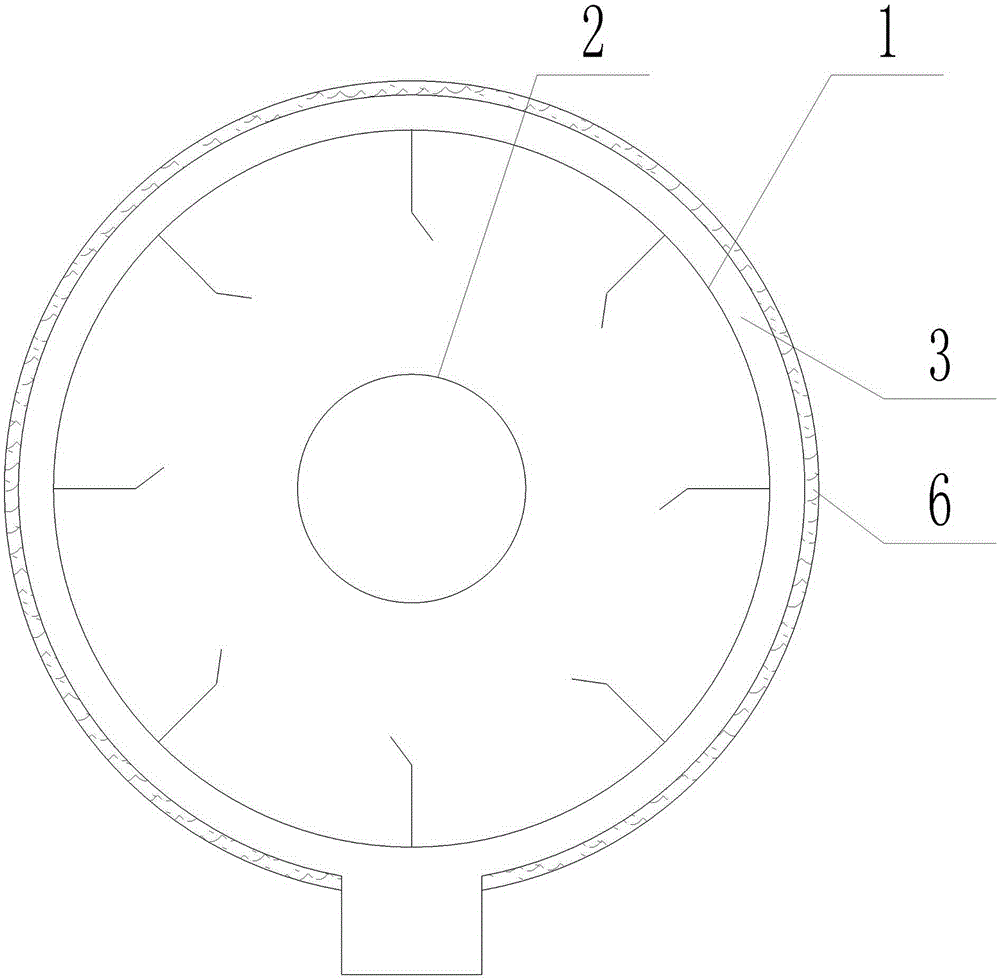

[0031] A high-efficiency and energy-saving drum drying and drying equipment, including a drum dryer and a drying furnace. The drum dryer includes: a main cylinder 1, a heat dissipation pipe 2, an attached cylinder 3, a front cover 4, a rear cover 5, Insulation layer 6; drying furnace includes: connecting elbow 7, furnace core 8, furnace wall 12, outer wall 13, fuel inlet pipe 14 and furnace bridge 15;

[0032] Among them, the outer wall of the attached cylinder 3 is attached with an insulating layer 6, and the front section of the attached cylinder 3 is provided with a flue gas outlet;

[0033] Both ends of the main cylinder are provided with cover plates, the front cover plate 4 is provided with material inlet and hot air inlet, and the rear end cover plate 5 is provided with material outlet and moisture outlet;

[0034] The front section of the heat dissipation pipe 2 extends from the hot air inlet of the front cover plate, and the rear section is connected to the main cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com