Sizing device for textiles

A technology of sizing roller and sizing, which is applied in the processing of textile materials, textiles and papermaking, and processing of textile material drums, etc. It can solve the problems of sizing waste, uneven sizing, and uneven spraying, etc., and achieves reduction in production costs and sizing High quality, uniform sizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: The embodiment of the present invention is illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention by the contents disclosed in this description, and quoted in this description as "upper end", Terms such as "lower end", "upper" and "lower" are only for the convenience of description, and are not used to limit the scope of the present invention. Be regarded as the scope that the present invention can implement.

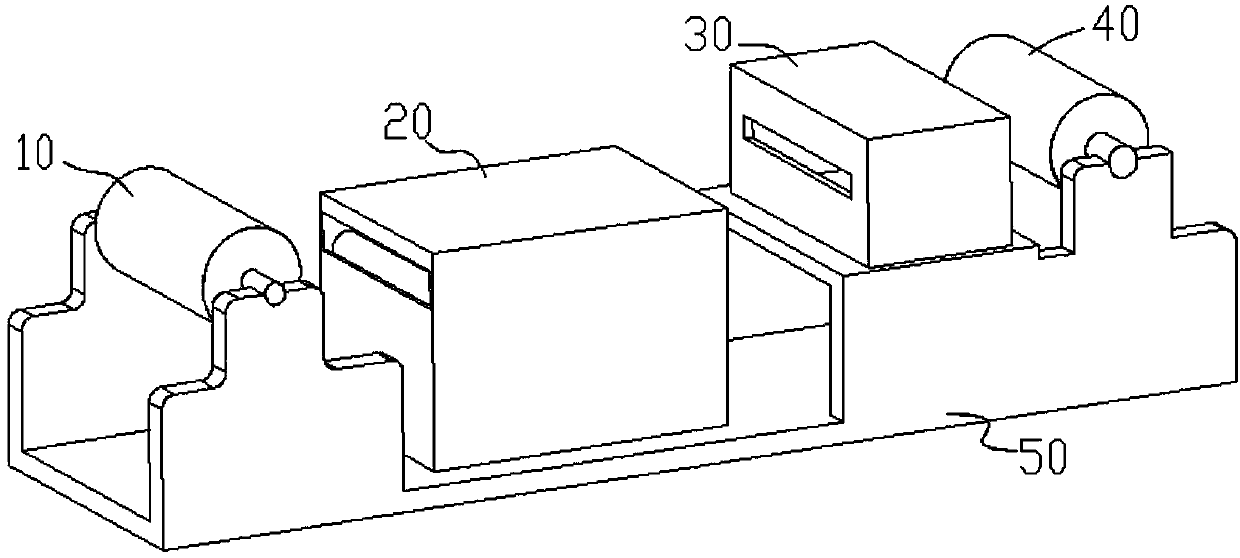

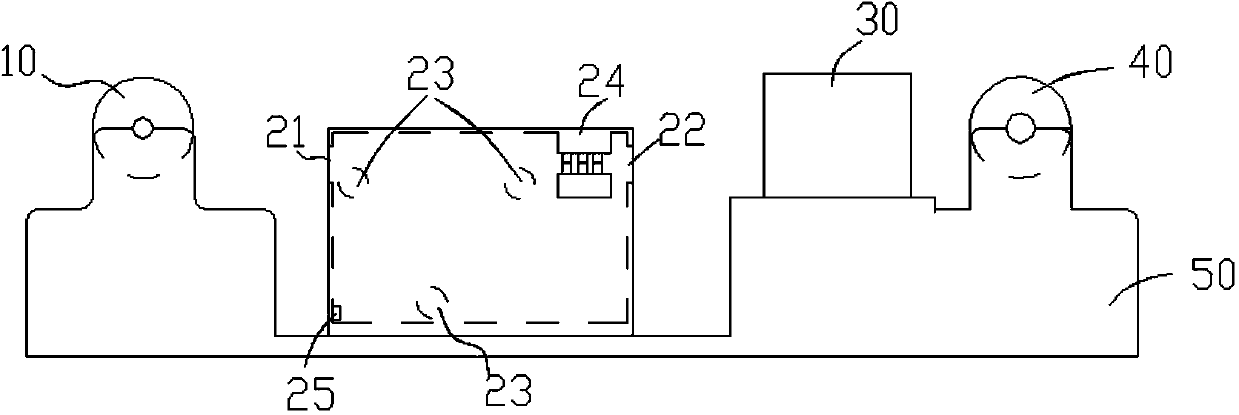

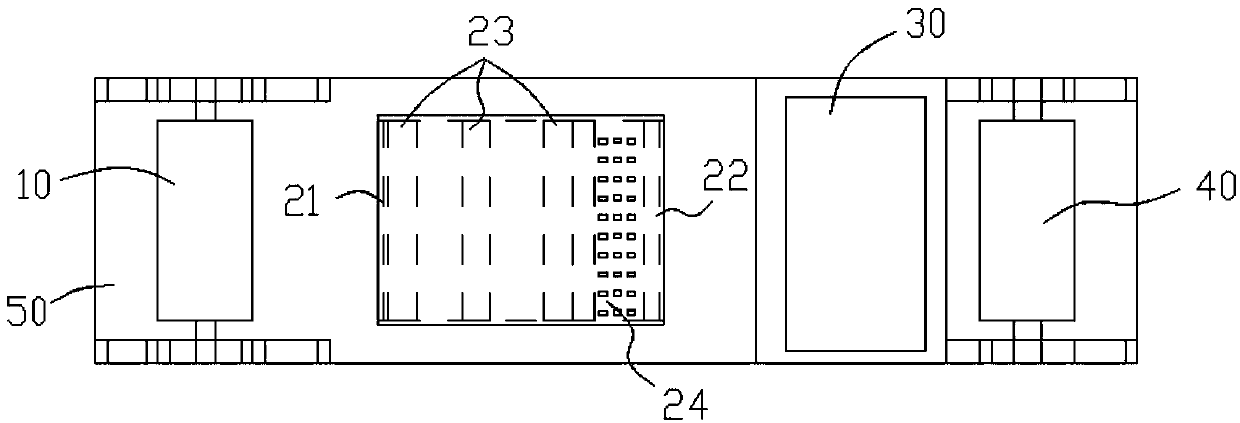

[0018] See Figures 1 to 3 As shown, a textile sizing device includes an unwinding roller 10 , a pulp storage box 20 , a drying box 30 , a winding roller 40 , and a bottom plate 50 .

[0019] The unwinding roller 10 and the winding roller 40 are fixed on the base plate 50, the power device of the unwinding roller 10 and the winding roller 40 is a servo motor, and the unwinding roller 10 and the winding roller 40 A pulp storage box 20 and a drying box 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com