Preparation method of Mosla chinensis volatile oil microcapsules

A technology of volatile oil and Radix japonica, applied in the field of volatile oil processing of Radix Radix et Rhizoma, can solve problems such as damage and loss of functional components of volatile oil of Radix Radix et Rhizoma, and achieve the effects of increasing the scope of application, short testing time, and rounded particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] After crushing, Jiangxiang sieves through a 40-mesh sieve, add 10-15 times of water, stir and soak for half an hour; add the volatile oil extractor to boil for 4 hours, collect the volatile oil from the lower end of the measuring device; add anhydrous sodium sulfate to the volatile oil Remove moisture. Prepare a 50°C homogeneous aqueous solution with a ratio of 25% of gum arabic and maltodextrin at a ratio of 5:5, add 12% of the core and wall material ratio of the volatile oil of Rhizoma chinensis, and stir evenly. Pass the emulsion through an ultrasonic cell crusher with a duty cycle of 5s-5s and work 60 times to emulsify the homogeneous emulsion. Stir the water bath at 60 °C for 4 h. The microcapsule powder is dried and collected by a spray dryer. The spray drying inlet air temperature is 220°C, and the outlet air temperature is 120°C.

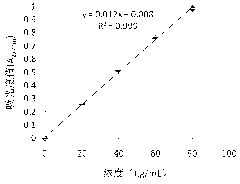

[0028] Determination of oil content on the surface of microcapsules by ultraviolet spectrophotometry: take a certain concentratio...

Embodiment 2

[0034] After crushing, Jiangxiang sieves through a 40-mesh sieve, add 10-15 times of water, stir and soak for half an hour; add the volatile oil extractor to boil for 4 hours, collect the volatile oil from the lower end of the measuring device; add anhydrous sodium sulfate to the volatile oil Remove moisture. Prepare a 60°C homogeneous aqueous solution with a ratio of 25% of gum arabic and maltodextrin in a ratio of 3:5, add 10% of the core and wall material ratio of the volatile oil of Rhizoma chinensis, and stir evenly. Pass the emulsion through an ultrasonic cell crusher with a duty cycle of 5s-5s and work 40 times to emulsify the homogeneous emulsion. Place in a water bath at 40°C for 4 h while stirring evenly. The microcapsule powder is collected by drying in a spray drying tower. The spray drying inlet air temperature is 180°C, and the outlet air temperature is 104°C. It has been determined that the microencapsulation efficiency of the volatile oil of Jiangxiangrui is...

Embodiment 3

[0036]After crushing, Jiangxiang sieves through a 40-mesh sieve, add 10-15 times of water, stir and soak for half an hour; add the volatile oil extractor to boil for 4 hours, collect the volatile oil from the lower end of the measuring device; add anhydrous sodium sulfate to the volatile oil Remove moisture. Prepare 30% concentration of gum arabic and maltodextrin in a ratio of 4:5 at 60°C and stir it uniformly for later use, add 10% of the core wall material ratio of the volatile oil of fenugreek, and stir evenly. Pass the emulsion through an ultrasonic cell crusher with a duty cycle of 5s-5s and work 50 times to emulsify the homogeneous emulsion. In a water bath at 40°C for 4 h, heating and stirring while in the water bath. The microcapsule powder is collected by drying in a spray drying tower. The inlet air temperature for spray drying is 200°C, and the outlet air temperature is 108°C. It has been determined that the microencapsulation efficiency of the volatile oil of J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com