Itaconic acid polymers for improved dirt and water resistance for elastomeric wall and roof coatings

A water-based composition, mixture technology, applied in the direction of roofing, roofing, coating, etc. using tile/slate, can solve the yellowing of the coating film, reduce low temperature flexibility, does not provide water swelling resistance and stain resistance Roof coating and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] Examples: The following examples illustrate the advantages of the invention.

[0079] Test Methods: The following test methods were used in the examples shown:

[0080] Mechanical properties: use the ASTM D-2370 (2010.12) standard to test the maximum tensile strength, the requirements are: use a minimum of 1.4 MPa and a 75 mm long and 13 mm wide sample, at a temperature of 23 ° C, a crosshead speed of 25 mm / min , the gauge length is 25 mm; use ASTM D-2370 (2010.12) standard to test the elongation at break, the sample is 75 mm long and 13 mm wide, at 23 °C, the crosshead speed is 25 mm / min, and the gauge length is 25 mm mm. Elongation must be 100% minimum after 1000 hours; exposure to Weather-O-Meter TM ): During the specified time, the Weather-O-Meter (Weather-O-Meter TM ) The accelerated weathering method adopts the ASTM D4798 (2011.1) standard; the cycle used is A, the temperature of the non-insulated blackboard is 63°C, and the daylight filter is used, and the t...

Embodiment 6

[0095] Example 6 was prepared according to the general copolymer synthesis method described above, except that when 50% of the total volume of the monomer emulsion had been added to the reactor flask (about 94 minutes after the start of feeding), 2.8 g n-DDM.

[0096] Synthesis of Copolymer 7 (Table 1):

Embodiment 7

[0097] Example 7 was prepared according to the general copolymer synthesis method described above, except that when 75% of the total volume of the monomer emulsion had been added to the reactor flask (about 137 minutes after the start of feeding), 2.8 g n-DDM.

[0098] Table 1: Emulsion copolymers containing itaconic acid:

[0099]

[0100] *CE1 polymer contained 0.3 wt% BZP, 0.3 wt% benzophenone was added to all other emulsion polymers prior to formulation.

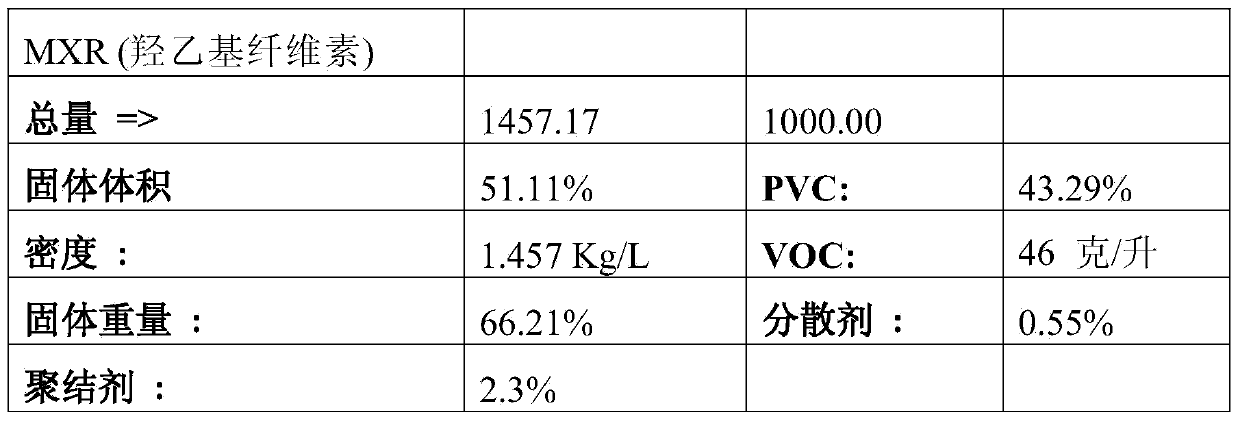

[0101] In Examples CE1 to 8 described in Table 1, the amount of itaconic acid varied between 0.21% and 1.21%. Examples 6 and 7 were prepared in the presence of 0.83% itaconic acid with the addition of 0.15% n-dodecyl mercaptan at 50% or 70% feed completion. Except where noted, all coating compositions were prepared from a 43% PVC / 51% volume solids formulation (shown in Table 1A below) with 47 lbs. of zinc oxide per 100 gallons. Unless otherwise stated, the coating compositions were formulated using a Kohlers high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com