Method for preparing high-quality graphene through electrochemical high-efficiency exfoliation

A graphene, high-quality technology, applied in the field of electrochemical high-efficiency stripping to prepare high-quality graphene, can solve the problems of high resistance, expensive preparation, and reduce production costs, etc., to achieve small resistance, high conductivity, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: the electrochemical high-efficiency exfoliation of this example prepares the method for high-quality graphene, and its steps are:

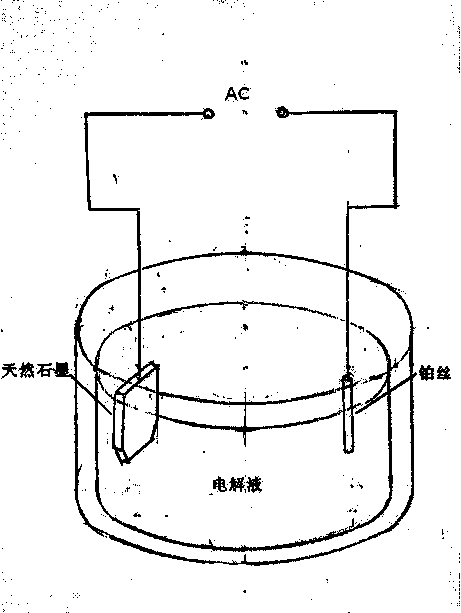

[0031] 1. In this example, natural flake graphite (NGF) (average size between 5 and 20 mm) is used as the positive electrode and the raw material for preparing graphene. The end face of the strip graphite is first drilled with Φ1 mm, and the tungsten wire is inserted into the hole after cleaning. Silver welding is used to weld the tungsten wire firmly, and it is integrated with the strip graphite, such as figure 1 , and then inserted into the ion solution as the anode, only the graphite is impregnated into the solution, the platinum wire is used as the ground electrode (negative electrode), placed parallel to the graphite sheet, and 50mm away from the strip graphite, take (2.4-4.8 g) of H 2 SO 4 (98%) into 100mL of deionized water and 11mL of 30% KOH solution as the electrolyte, the pH value is 10-12 and added into the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com