Tensile strain germanium msm photodetector and method for making the same

A technology of photodetector and manufacturing method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as poor photodetection performance, and achieve the effects of improving photodetection performance, increasing absorption coefficient, and increasing bending degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The present invention provides a method for fabricating a tensile strain germanium MSM photodetector, which at least includes the following steps:

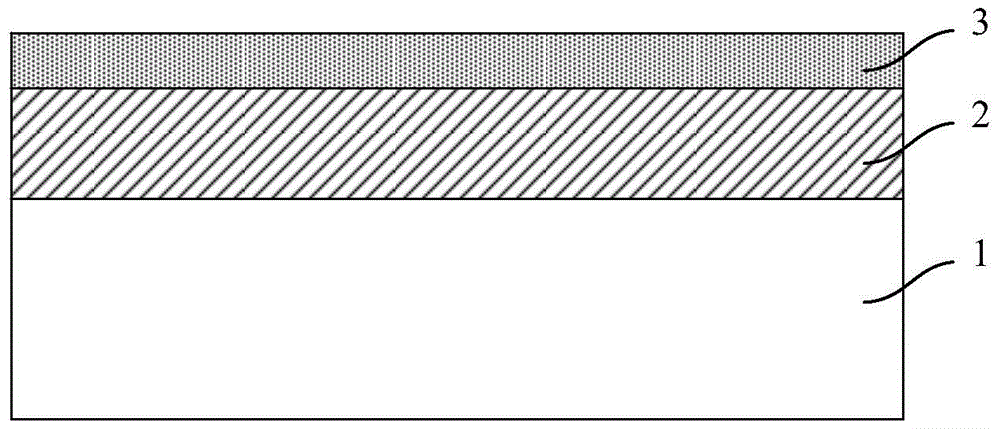

[0072] Step S1: providing a substrate, and sequentially forming a sacrificial layer and a germanium layer on the substrate;

[0073] Step S2: forming a metal layer on the germanium layer, and the metal layer provides stress to the germanium layer;

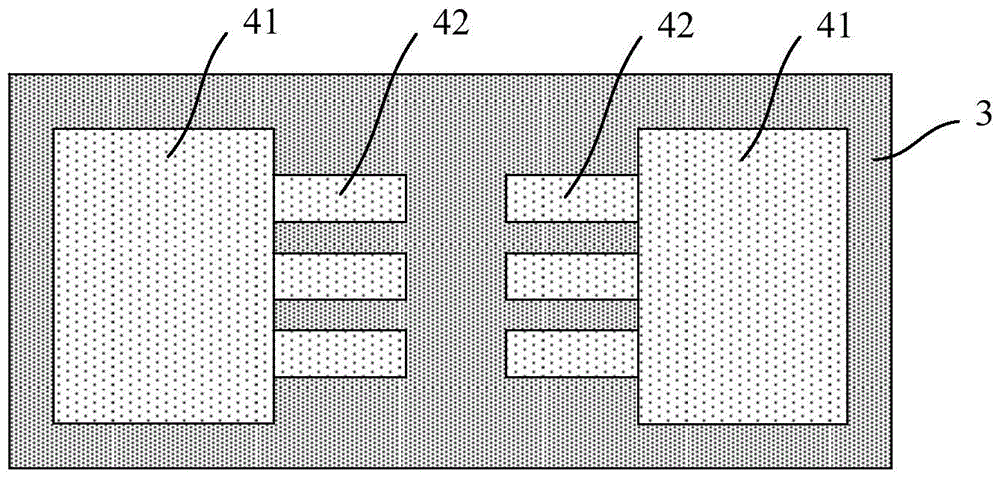

[0074] Step S3: patterning the metal layer to form a pair of metal main bases and at least a pair of metal sub-bases connected to the pair of metal main bases;

[0075] Step S4 : patterning the germanium layer to form a germanium main pedestal and a germanium sub-susceptor under the metal main susceptor and the metal sub-susceptor, respectively, and at least one strip is formed between each pair of germanium sub-susceptors germanium bridge wire;

[0076] Step S5: Etching away the sacrificial layer under the germanium bridge line and under the germanium submount, so that the ge...

Embodiment 2

[0093] This embodiment adopts basically the same technical solution as the first embodiment, and the difference lies in that, in this embodiment, metal wires connected to the metal submount are respectively formed above both ends of the germanium bridge wire.

[0094] see Figure 7 , which is shown as a top view of the structure in which metal lines 43 connected to the metal submount 42 are respectively formed above both ends of the germanium bridge line 33 . The metal lines 43 are formed simultaneously with the metal main pedestal 41 and the metal sub-mount 42 during the patterning process of the metal layer 4 . The width of the metal line is preferably equal to the width of the germanium bridge line.

[0095] Forming the metal wires 43 above both ends of the germanium bridge wire 33 can further reduce the shear force on the germanium bridge wire during the film deformation process, protect the germanium bridge wire from breaking, improve the stability of the MSM photodetect...

Embodiment 3

[0097] This embodiment adopts basically the same solution as the first embodiment or the second embodiment, the difference is that the uniaxial stress tensile strain germanium is formed in the first embodiment and the second embodiment, while the biaxial stress tensile strain can be formed in this embodiment. The strained germanium can be realized only by changing the pattern of the metal layer 4 and the germanium layer 3 during the patterning process.

[0098] Specifically, in the step S3, the metal layer is patterned to form two pairs of horizontal and vertical metal main bases, and a pair of metal sub-bases is connected between each pair of metal main bases; In step S4, two germanium bridge lines that are vertically connected are formed between the two pairs of germanium submounts; and in the step S5, after etching, the connection of the two germanium bridge lines is in both the lateral and vertical directions stretched to form biaxially stressed tensile strain germanium. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com