Method for acquiring thermal performance of oxygen-enriched combustion boiler

A technology of oxygen-enriched combustion and thermal performance, which is applied in the direction of instruments, calculations, electrical digital data processing, etc., and can solve problems such as not being able to adapt to new oxygen-enriched combustion boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

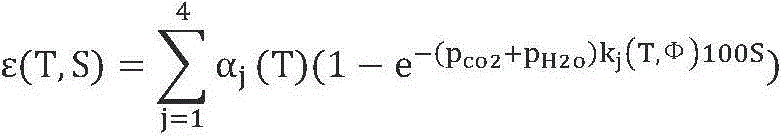

Method used

Image

Examples

Embodiment 1

[0168] The method for checking the thermal performance of the oxygen-enriched combustion boiler provided by the present invention checks the cold-dry cycle type oxygen-enriched combustion boiler:

[0169] The boiler to be checked is a cold-dry circulation type oxygen-enriched combustion boiler. Design requirements: see "Boiler Thermal Calculation Standard" (1973 Edition)

[0170] See Table 1 for the operating parameters of the boiler to be checked; see Table 2 for the coal quality parameters.

[0171] Table 1 Boiler operating parameters

[0172] Maximum continuous evaporation

t / h

695

Superheater outlet steam pressure

MPa.(a)

13.4

Superheater outlet steam temperature

℃

538

Reheat steam flow

t / h

595

Reheater inlet steam pressure

MPa.(a)

3

Reheater inlet steam temperature

℃

331

Reheater outlet steam pressure

MPa.(a)

2.85

Reheater outlet steam temperature

℃

53...

Embodiment 2

[0181] For the design requirements of the cold-dry circulation type oxygen-enriched combustion boiler, see step (1); the calculation results are as follows,

[0182] Under the oxygen-enriched combustion cold-wet cycle atmosphere, the value of cycle rate is 0.710; the purity of oxygen in the air separation system is 98%; the peroxygen coefficient is 1.2; the leakage coefficient is 0.015; the water vapor content after condensation is 4%; The proportion of hot air is 0.7; the proportion of primary air oxygen injection is 18%.

[0183] Initialized flue gas volume: 7.613Nm 3 / kg, number of iterations: 500; calculation result: smoke volume V 1 : 6.223Nm 3 / kg; smoke emission 1.331Nm 3 / kg; circulating flue gas volume 4.417Nm 3 / kg; primary air volume of assisted gas 1.336Nm 3 / kg; gas secondary air volume 4.399Nm 3 / kg; air supply volume of air separation unit V kf : 1.318Nm 3 / kg

Embodiment 3

[0185] Under the oxygen-enriched combustion thermal cycle atmosphere, the cycle rate value is 0.678; the oxygen purity of the air separation system is 97.5%; the oxygen peroxide coefficient is 1.05; the leakage coefficient is 0.01; the water vapor content after condensation is 3%; the primary air share is 0.266; the hot air in the primary air The share is 0.7; the proportion of primary air oxygen injection is 18%.

[0186] Initialized flue gas volume: 7.613Nm 3 / kg, number of iterations: 500; calculation result: smoke volume V 1 : 5.523Nm 3 / kg; smoke emission 1.291Nm 3 / kg; circulating flue gas volume 3.742Nm 3 / kg; primary air volume of assisted gas 1.337Nm 3 / kg; gas secondary air volume 3.681Nm 3 / kg; air supply volume of air separation unit V kf of: 1.276Nm 3 / kg.

[0187] The thermal calculation of each heating surface is as follows: panel superheater: error is -1.02%; convection superheater: error is -0.34%; reheater: error is 0.25%; economizer: error is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com