Multi-channel three-cavity silencer

A muffler, multi-channel technology, applied in mufflers, machines/engines, engine components, etc., can solve problems such as single airflow channel and loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

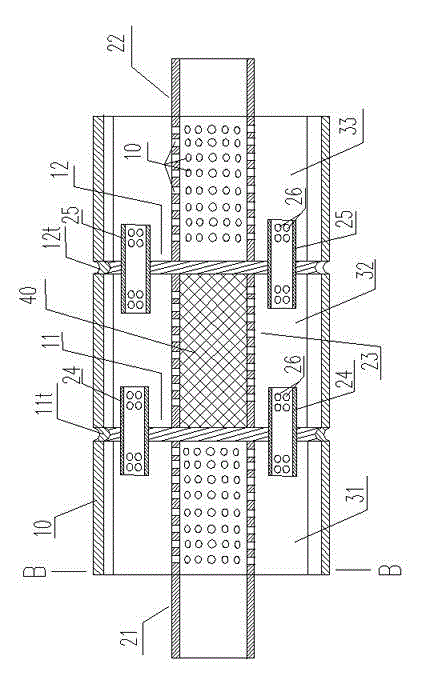

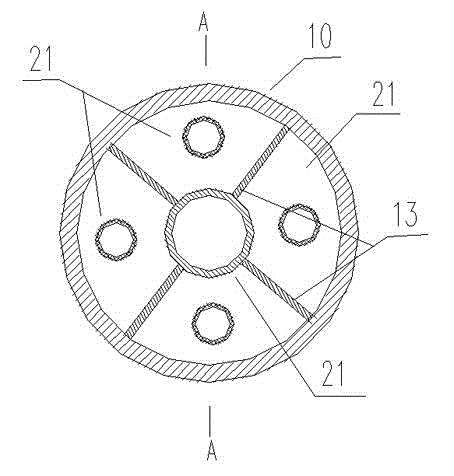

[0017] Embodiment 1 of the present invention is, as figure 1 , figure 2 As shown, it includes a muffler cylinder 10, an intake pipe 21, an exhaust pipe 22, and also includes a first chamber partition 11 and a second chamber partition 12. The first chamber partition, the second chamber The clapboard divides the muffler cylinder into a first chamber group 31, a second chamber group 32, and a third chamber group 33. The inlet pipe 21 extends into the first chamber group, and the exhaust pipe 22 extends into the first chamber group. Entering the third chamber group, the second chamber group in the middle is provided with a second chamber central pipe 23 across the chamber, and a plurality of partition plates 13 are arranged in each chamber group, and the The interlayer partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com