Yarn tension device for warp knitting machine

A yarn tension and warp knitting machine technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problem of affecting the quality of cloth surface and production efficiency, affecting the accuracy and uniformity of yarn feeding, and cannot guarantee yarn tension Uniformity and other problems, to achieve the effect of good gray cloth quality, high production efficiency, and constant air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

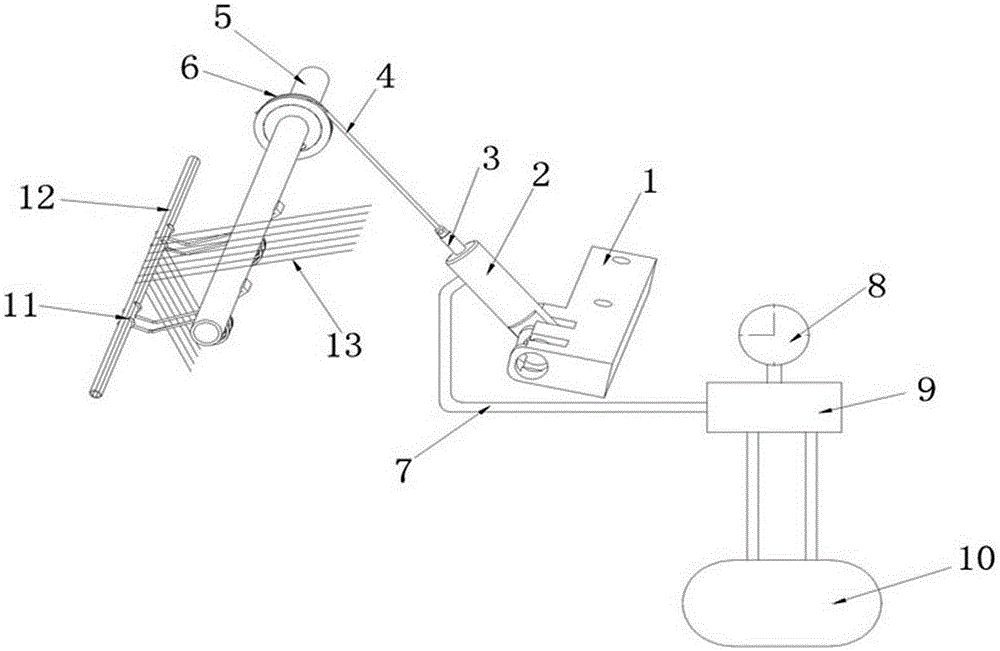

[0010] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0011] As shown in the figure, a yarn tension device for a warp knitting machine includes a cylinder holder (1), a cylinder (2), a cylinder puller (3), a steel rope (4), a yarn passing rod (5), a rotary Wheel (6), air supply pipe (7), pressure gauge (8), valve (9), air storage tank (10), tension spring (11), yarn guide cap (12), yarn (13), its main features The pressure is adjusted through the tension of the yarn (13), so as to ensure constant air pressure and stable tension of the yarn (13).

[0012] The yarn tension device of a warp knitting machine is provided with a cylinder fixing seat (1) installed on the wallboard or main beam of the warp knitting machine, and the cylinder fixing seat (1) is provided with an air inlet. One end of the cylinder (2) is positioned on the cylinder fixing seat (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com