Preparation method for ultra-fine grain pure titanium through equal channel angular pressing

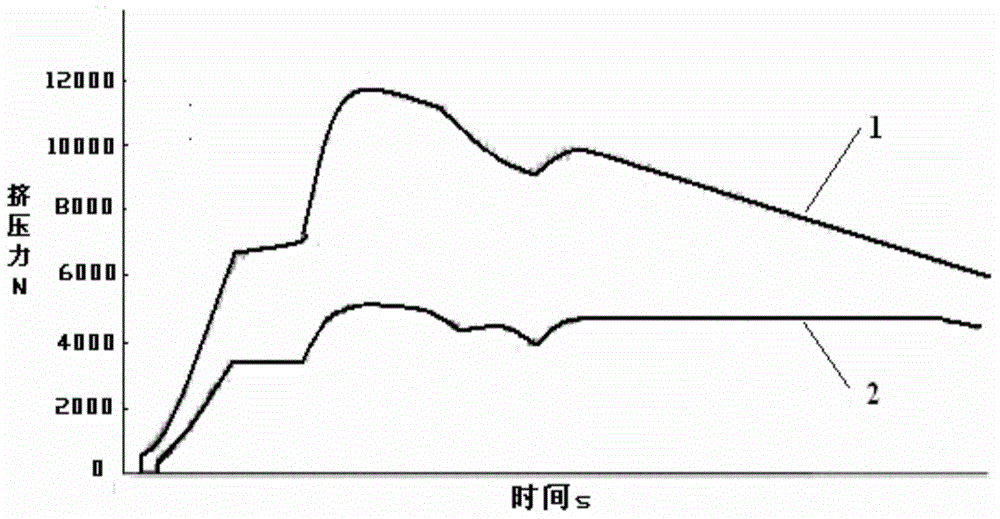

A technology of ultra-fine-grained pure titanium and equal-diameter channels, which is applied in the field of plastic processing of materials, can solve problems such as excessive extrusion force, achieve the effects of reducing extrusion force, improving comprehensive mechanical properties, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

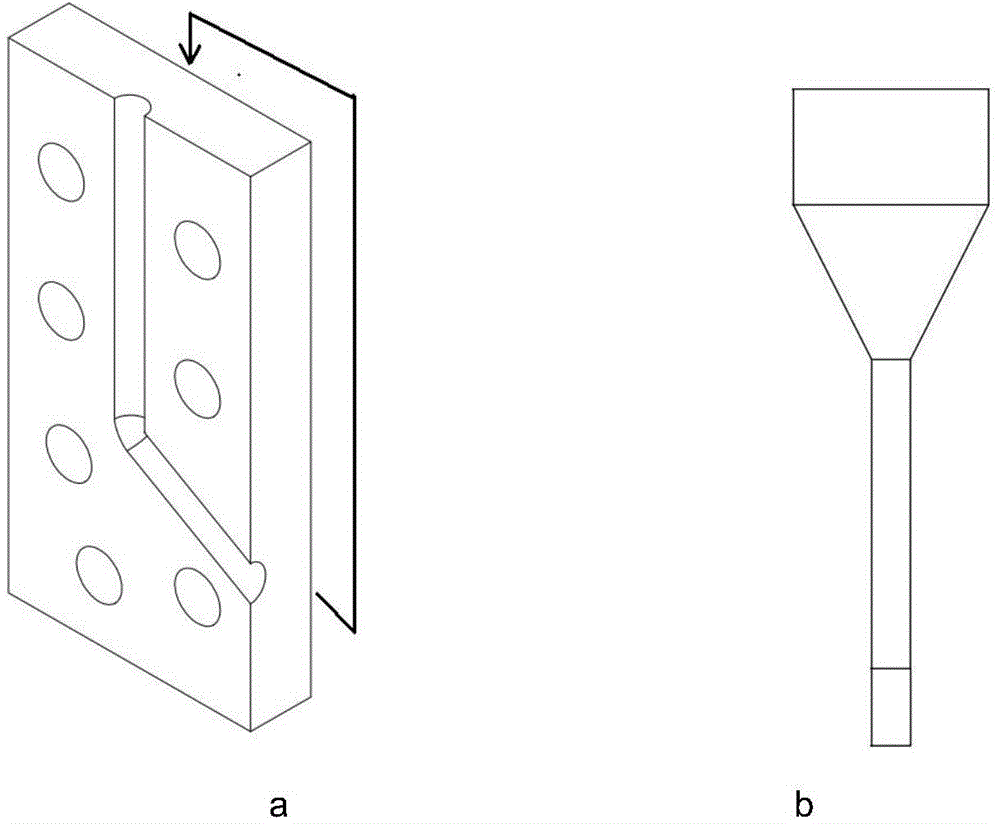

[0043] The mold used in this embodiment adopts the prior art, including two half molds, extrusion rods and some bolts, such as figure 2 shown in a and 2b. Before extrusion, evenly apply a layer of compound lubricant inside the channel, and put the extrusion rod into the channel, so that the extrusion rod can play a role in positioning and prevent the dislocation of the two halves during installation; Two symmetrical mold halves are assembled to form a complete mold with a channel inner angle of 120° and an outer corner of 20°. The extrusion route selects the Bc route with the best refinement effect, that is, after each pass of extrusion, the extrusion sample is rotated 90° clockwise and then put into the entrance channel again; adjust the downward movement speed of the beam of the universal testing machine, Make the extrusion rod move down along the channel at a speed of 0.5-1.5mm / s. In this embodiment, the downward movement speed of the extrusion rod is 0.5 mm / s.

[0044] ...

Embodiment 2

[0062] The mold selected in this embodiment is a mold composed of two halves with a channel angle of 120° and an outer fillet of 20°. The extrusion route selects the Bc route with the best refinement effect, that is, after each pass of extrusion is completed, the The extrusion sample is rotated 90° clockwise and put into the entrance channel again; the extrusion rod moves down the channel at a speed of 0.5mm / s, which can be controlled by adjusting the speed of the beam of the universal testing machine. This embodiment is operated at normal temperature.

[0063] The concrete process of this embodiment is:

[0064] Step 1, preparation of copper-titanium sample:

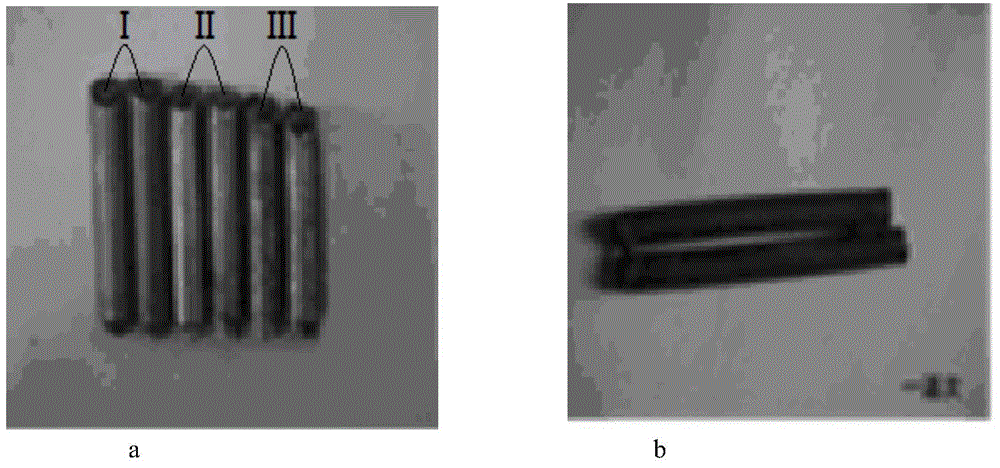

[0065] Cut the industrial pure titanium TA2 hot-rolled plate into a cylinder with a length of 70 mm and a diameter of 8 mm to make a titanium rod. One end of the titanium rod is a cone.

[0066] Cut the pure copper into a cylinder with a length of 80 mm and a diameter of 10 mm to make a copper rod. A tapered blind h...

Embodiment 3

[0082] The selected mold used in this embodiment is a mold composed of two halves with a channel angle of 90° and an outer fillet angle of 30°. Die channel angle and outer fillet are important parameters that affect the amount of deformation of the extrusion sample after each pass of extrusion. Reducing the channel angle can effectively increase the plastic deformation of each pass of the extrusion sample and increase the Rounded corners can make it easier for the specimen to pass through the corners. The extrusion route selects the Bc route with the best refinement effect, that is, after each pass of extrusion, the extrusion sample is rotated 90° clockwise and then put into the entrance channel again; the extrusion rod moves down the channel at a speed of 1.5mm / s, it can be controlled by adjusting the downward movement speed of the beam of the universal testing machine. This embodiment is operated at normal temperature.

[0083] The concrete process of this embodiment is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flow stress | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com