Method of preparing humic acid by biological sludge composting

A bio-sludge and humic acid technology, applied in the direction of fermentation, can solve the problems of high pharmaceutical cost, high operating cost, long use time, etc., and achieve the effect of good market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

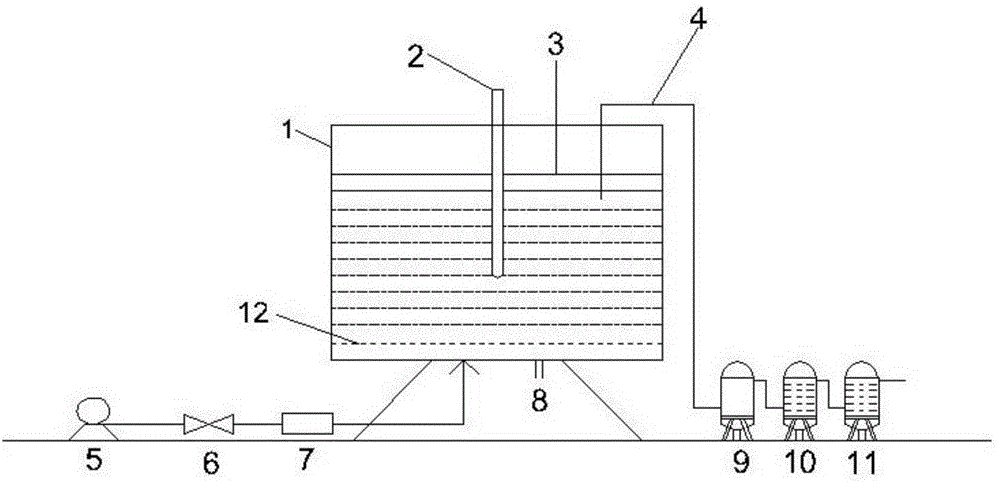

Embodiment 1

[0026] Get 10kg of dewatered sludge and 6kg of fallen leaves with a water content of 15% to mix, the water content of the mixed material reaches 55.6%, and the carbon-nitrogen ratio (C / N) reaches 26.3. Put the mixed materials evenly into the aerobic fermentation tank, and provide air to the pile through the aeration system at the bottom of the fermentation tank. 3 / (h·m 3 Stacking) to adjust the air volume. The outlet gas is collected by the air guide tube, and then passes through the condensation device and the gas collection device respectively equipped with 10% NaOH and 0.1mol / L HCl absorption liquid, and then empties after purification. After 45 to 60 days of fermentation and decomposing, the decomposed fertilizer samples are naturally air-dried, pulverized by a pulverizer and sieved, and the under-sieve is used as the raw material for humic acid extraction.

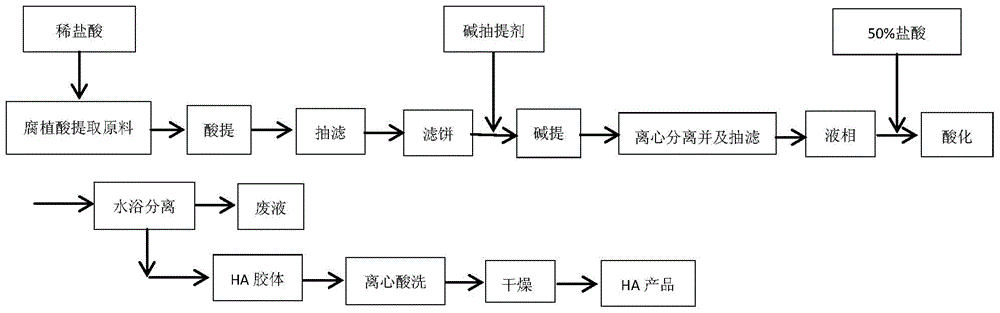

[0027] Take 15g of humic acid extraction raw material, put it into a 250ml Erlenmeyer flask, add 150ml of 10% di...

Embodiment 2

[0029] Composting process is with embodiment 1. The humic acid extraction and separation process is similar to Example 1. The difference is that the solid-liquid ratio of alkali extraction is 1:9, the extraction temperature is 80°C, and the extraction time is 100min. The product quality of humic acid was 2.6045g, and the recovery rate of humic acid was 40.63%.

Embodiment 3

[0031] Composting process is with embodiment 1. The humic acid extraction and separation process is similar to Example 1. The difference is that the solid-liquid ratio of alkali extraction is 1:10, the extraction temperature is 90°C, and the extraction time is 110 minutes. The product quality of humic acid was 2.6032g, and the recovery rate of humic acid was 43.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com