Polyethylene rubber and processing method thereof

A technology of polyethylene rubber and hyperbranched polyethylene, which is applied in the field of rubber, can solve the problems of high glass transition temperature of polyethylene, limitation of catalyst chain walking ability, and insufficient branching degree of polyethylene, so as to achieve good mechanical properties and improve additional Value, the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

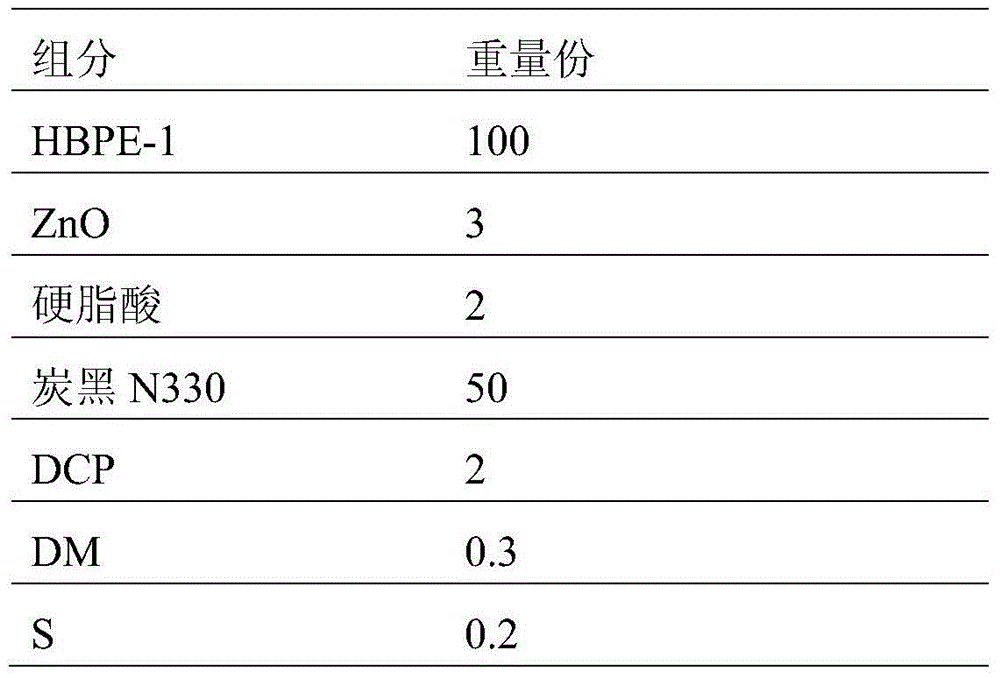

[0029] The processing formula of table one embodiment 1

[0030]

[0031] With the degree of branching as 106 branched chains / 1000 carbons (wherein the methyl content is 50.6 mol%, the ethyl content is 13.2 mol%, the propyl content is 6.7 mol%, the butyl content is 4.9 mol%, the amyl content 3.7mol%, the branched chain content of carbon number ≥ 6 is 20.8mol%), the glass transition temperature is -65°C, the weight average molecular weight is 250,000, and the Mooney viscosity ML(1+4) is 16.75 at 125°C. Polyethylene (HBPE-1) is the main raw material, and the components of the processing formula and the parts by weight of each component are as shown in Table 1.

[0032] The processing steps are as follows:

[0033] Step (1) Set the initial temperature of the internal mixer to 40°C, set the rotor speed to 50 rpm, and keep the temperature for 10 minutes after the temperature stabilizes.

[0034] Step (2) After adding 100 parts by weight of polyethylene and masticating for 1.5 ...

Embodiment 2

[0039] Change the stretching speed of step (5) in embodiment 1 to 500 mm / min, and other conditions are constant.

Embodiment 3

[0041] Change the vulcanization temperature of step (4) in Example 2 to 170° C., change the vulcanization time to 15 minutes, and keep other conditions constant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com