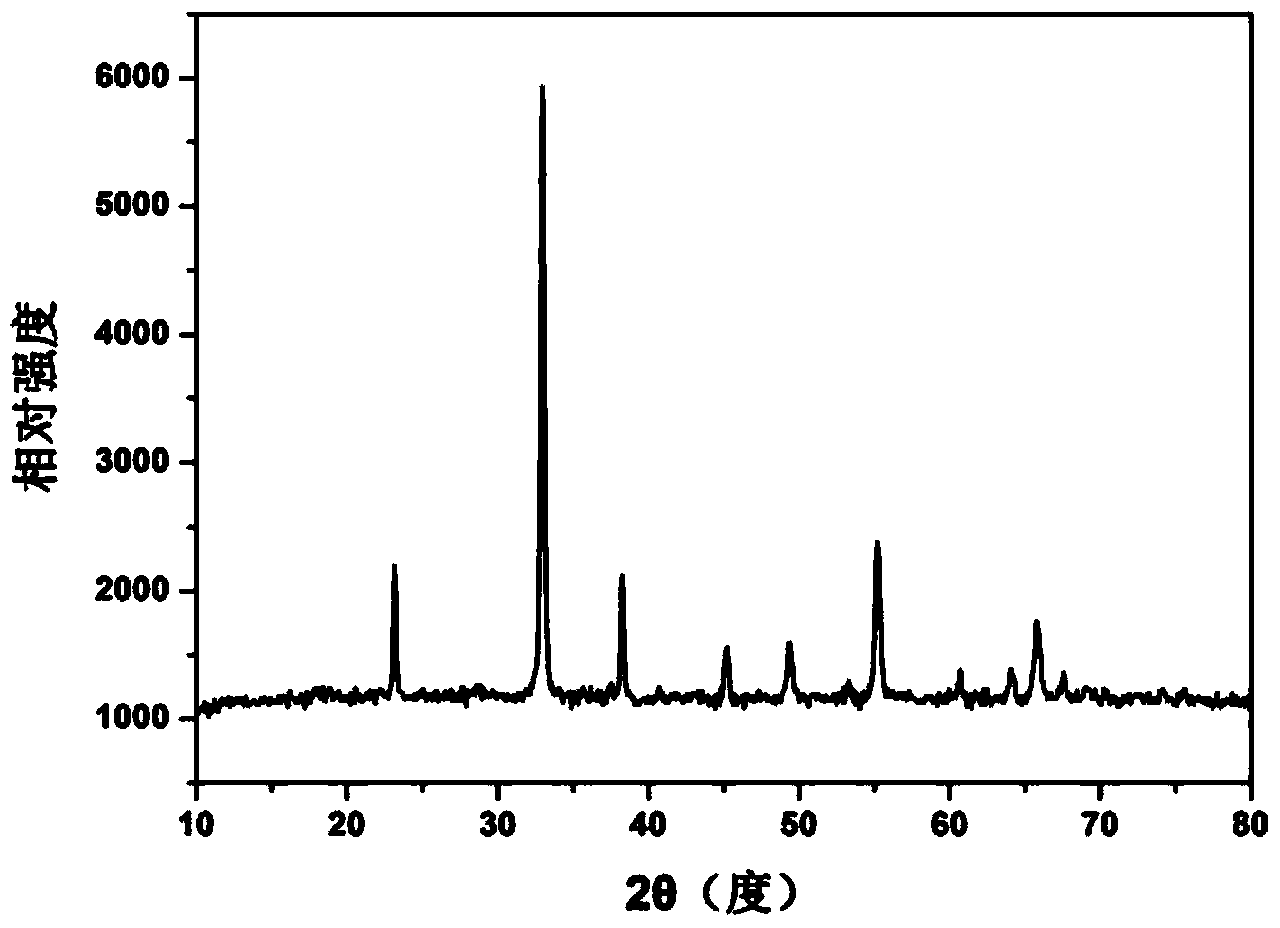

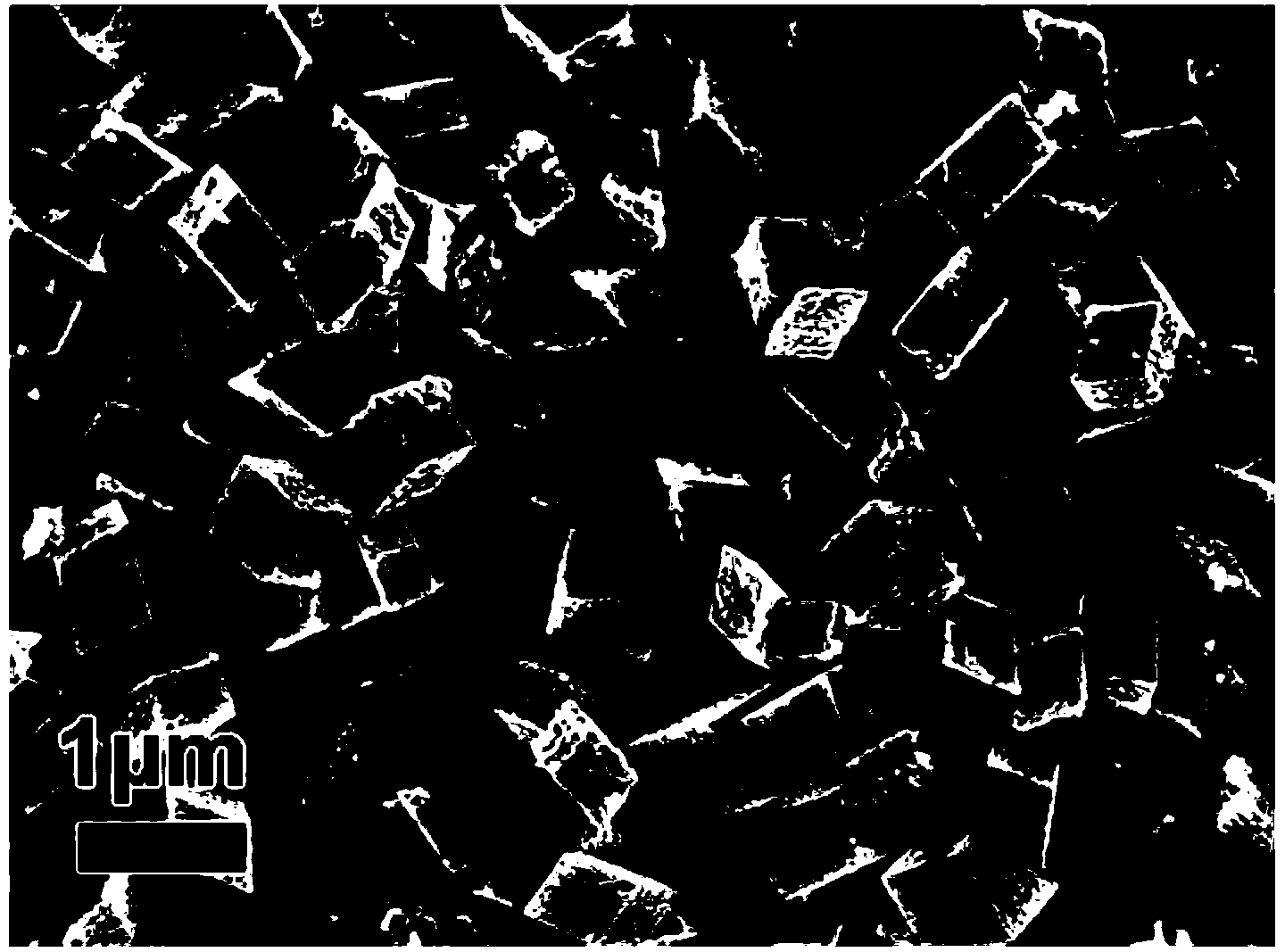

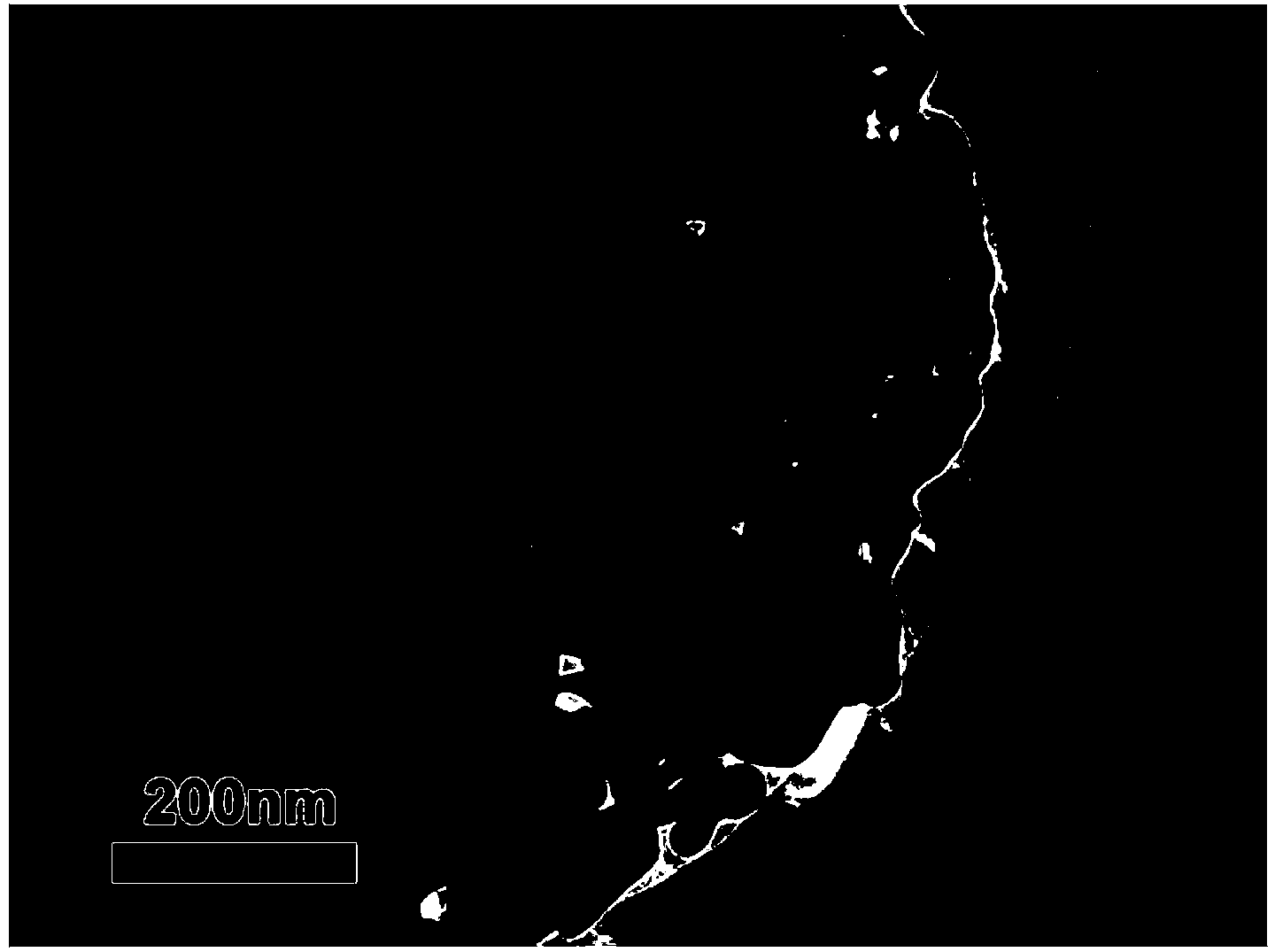

Porous manganic oxide cube as well as preparation method and application thereof

A technology of manganese trioxide and cubes, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of high reaction temperature, unfavorable large-scale application, particle agglomeration, etc., and achieve safe and stable reaction, multi-intercalated lithium/ Effects of delithiation active sites and raw material safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of synthetic method of porous manganese trioxide cube, comprises the following steps:

[0042] (1) Add 0.003mol potassium permanganate to 50mL ethylene glycol, stir for 30min to obtain a dark yellow liquid, dissolve 0.015mol ammonium bicarbonate in 6mL water, stir for 15min, then add the aqueous solution of ammonium bicarbonate to permanganese In the ethylene glycol solution of potassium acid potassium, stir for 30 minutes to form a uniform and transparent liquid;

[0043] (2) Transfer the mixed solution described in step (1) into a 150mL flask, place it on an oil bath and stir at a speed of 1200r / min, heat up from room temperature to 90°C, and then react at a constant temperature of 90°C for 7h , condensed and refluxed during the reaction, and then cooled naturally to obtain gray-white precipitates of manganese carbonate;

[0044] (3) the manganese carbonate precipitation that step (2) obtains is placed on the centrifuge and washed alternately with water and et...

Embodiment 2

[0049] A kind of synthetic method of porous manganese trioxide cube, comprises the following steps:

[0050] (1) Add 0.003mol potassium permanganate to 35mL ethylene glycol, stir for 30min to obtain a dark yellow liquid, dissolve 0.015mol ammonium bicarbonate in 15mL water, stir for 15min, then add the aqueous ammonium bicarbonate solution to the permanganese In the ethylene glycol solution of potassium acid potassium, stir for 30 minutes to form a uniform and transparent liquid;

[0051] (2) Transfer the mixed solution obtained in step (1) into a 150mL flask, place it on an oil bath and stir at a speed of 1200r / min, heat up from room temperature to 80°C, and then react at a constant temperature of 80°C for 9h, Condensate and reflux during the reaction, and then cool naturally to obtain gray-white precipitates of manganese carbonate;

[0052] (3) the manganese carbonate precipitation that step (2) obtains is placed on the centrifuge and washed alternately with water and ethan...

Embodiment 3

[0057] A kind of synthetic method of porous manganese trioxide cube, comprises the following steps:

[0058] (1) Add 0.003mol potassium permanganate to 35mL ethylene glycol, stir for 30min to obtain a dark yellow liquid, dissolve 0.015mol ammonium bicarbonate in 30mL water, stir for 15min, then add the aqueous solution of ammonium bicarbonate to permanganese In the ethylene glycol solution of potassium acid potassium, stir for 30 minutes to form a uniform and transparent liquid;

[0059] (2) Transfer the mixed solution obtained in step (1) into a 150mL flask, place it on an oil bath and stir at a speed of 1200r / min, heat up from room temperature to 80°C, and then react at a constant temperature of 80°C for 9h, Condensate and reflux during the reaction, and then cool naturally to obtain gray-white precipitates of manganese carbonate;

[0060] (3) the manganese carbonate precipitation that step (2) obtains is placed on the centrifuge and washed alternately with water and ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com