Hydraulic automatic cleaning device for coal bunker and cleaning method thereof

A hydraulic automatic and coal bunker technology, applied in the field of mining machinery, can solve the problems of poor effect, low efficiency of mechanical dredging method, life of severe noise devices, etc., achieve accurate operation control throughout the whole process, reduce labor costs and hidden safety hazards, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

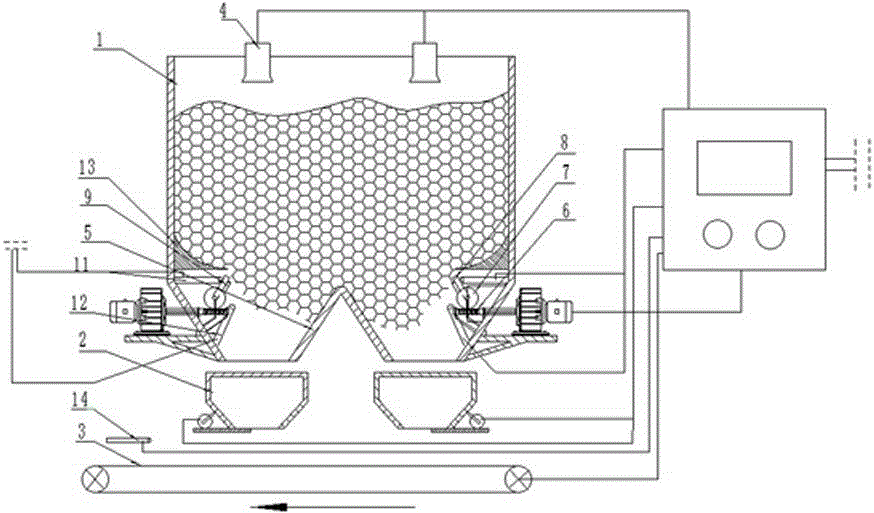

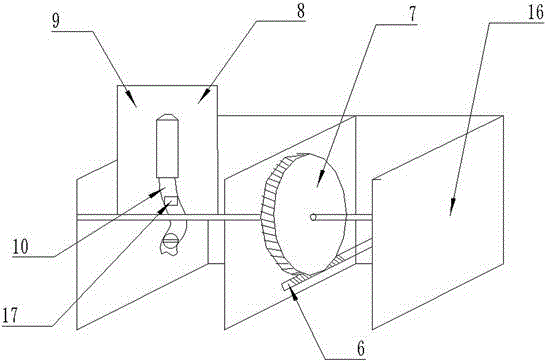

[0024] A coal bunker hydraulic automatic blockage removal device, which includes a coal storage bunker 1, two frequency conversion coal feeders 2, a belt conveyor 3, and a material level gauge 4 for monitoring the amount of coal stored above the coal storage bunker 1, including a PLC The control cabinet 15, the coal flow sensor 14 arranged above the belt conveyor 3, and the side wall of the chute 5 under the coal storage bunker 1 are provided with a hydraulic coal cleaning device for coal discharge, and the hydraulic coal cleaning device includes a set The variable frequency servo motor drive device on the outside of the chute 5 under the storehouse is arranged on the worm screw 6 connected to the output shaft of the frequency conversion servo motor drive device on the inner wall of the chute 5 under the storehouse, and the worm screw 6 is arranged on the inner wall of the chute 5 under the storehouse. The worm gear 7 with transmission, the nozzle protection plate 8 that swings...

Embodiment 2

[0031] In embodiment 2, except that there are three coal feeders 2, three chutes 5 under the coal storage bin 1, and two hydraulic coal cleaning devices for coal discharge are arranged on the side wall of the under bin chute 5, All the other devices are the same as the coal bunker hydraulic automatic declogging device described in Embodiment 1.

[0032] A method for unclogging utilizing the above-mentioned coal bunker hydraulic automatic unclogging device, which comprises the following steps:

[0033] 1. When the amount of coal stored in the coal storage is 1000 tons, set a low limit value of 4m for the material level gauge on the coal storage bunker, and set two opening values of 25 Hz and 50 Hz for the coal feeder;

[0034] 2. The low limit value set by the PLC control cabinet for the material level gauge on the coal storage bin is 4m. When the actual material level in the coal storage bin is greater than the set low limit value of 4m, the coal feeding is controlled manual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com