Resistance spot welding method of aluminium matrix composites

An aluminum-based composite material and resistance spot welding technology, which is applied in the direction of resistance welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problem of small tensile shear force, low joint strength and small nugget diameter of spot welded joints and other problems, to achieve the effect of simple and convenient welding process, reduce equipment damage, and improve tensile and shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

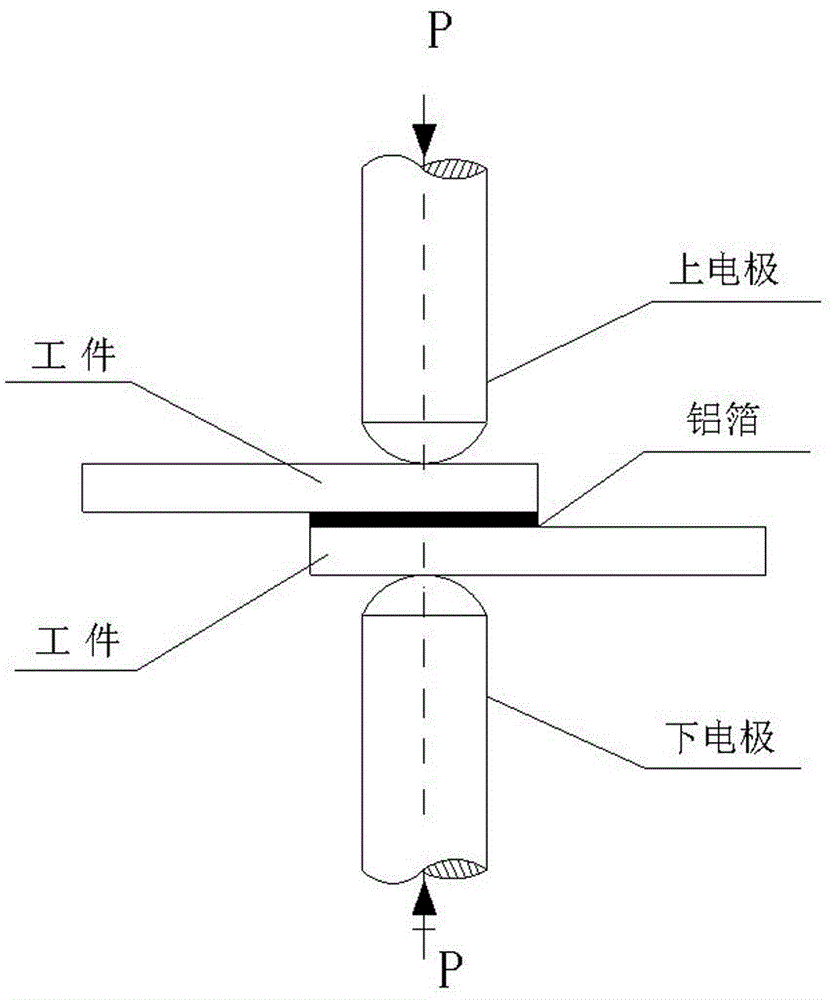

[0056] The matrix of the aluminum-based composite material used in the present invention is 2A12 (LY12), and the reinforcing phase is silicon carbide particles; the aluminum-based composite material is used as a plate with equal thickness on both sides, and is processed into a workpiece with a specification of 45×25×1.5mm. The lap length of the aluminum matrix composite material sample is 15mm when welding; the surface and back of the aluminum matrix composite material are sanded with sandpaper before resistance spot welding, the surface oxide film is removed, and then cleaned with acetone and air-dried; the pure aluminum foil used Smooth and flat, and cleaned with acetone and allowed to air dry before resistance spot welding.

[0057] When resistance spot welding is performed on an aluminum matrix composite material whose matrix is 2A12 (LY12) and the reinforcing phase is silicon carbide particles, a pure aluminum foil with a thickness of 6 μm is added between the processed ...

Embodiment 2

[0059] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0060] When resistance spot welding is performed on an aluminum matrix composite material with a matrix of 2A12 (LY12) and a reinforcing phase of silicon carbide particles, a pure aluminum foil with a thickness of 5 μm is added between the processed samples of the aluminum matrix composite material. When a pure aluminum foil is added between the materials for spot welding connection, the preload time is 1.5 seconds, the holding time is 1.8 seconds, the electrode pressure is 3200 Newton, the welding time is 0.5 seconds, and the welding current is 19.0 kA.

[0061] The shape of the electrode tip of the spot welder used in the above embodiments is a flat electrode.

Embodiment 3

[0062] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0063] When resistance spot welding is performed on an aluminum matrix composite material with a matrix of 2A12 (LY12) and a reinforcing phase of silicon carbide particles, a pure aluminum foil with a thickness of 7 μm is added between the processed samples of the aluminum matrix composite material. When a pure aluminum foil is added between the materials for spot welding connection, the preload time is 1.0 seconds, the holding time is 1.2 seconds, the electrode pressure is 2800 Newton, the welding time is 0.4 seconds, and the welding current is 17.5 kA.

[0064] The electrode tip shape of the spot welder used in the above embodiments is a dome surface electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com