Nano needle-like nickel-coated graphite compound particle and preparation method and application thereof

A technology of nickel-coated graphite and composite particles is applied in the field of synthesizing nano-acicular nickel-coated graphite composite particles for p-aminophenol and its preparation, which can solve the problems of difficult recovery, small particle size and the like, achieves low cost, prevents agglomeration, and is convenient for The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

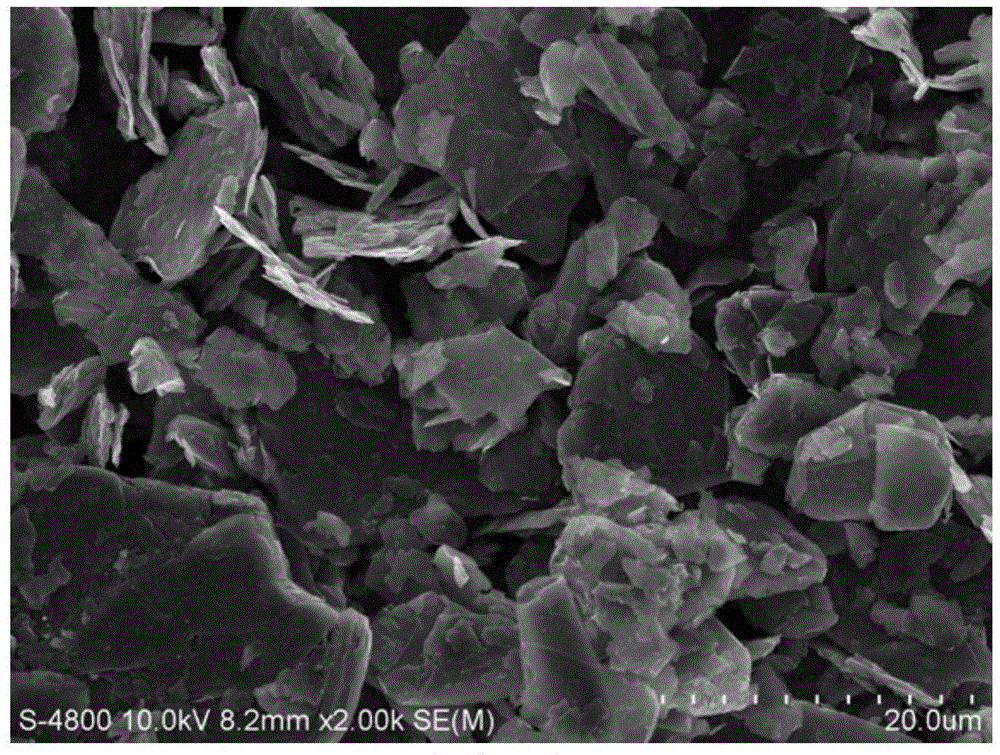

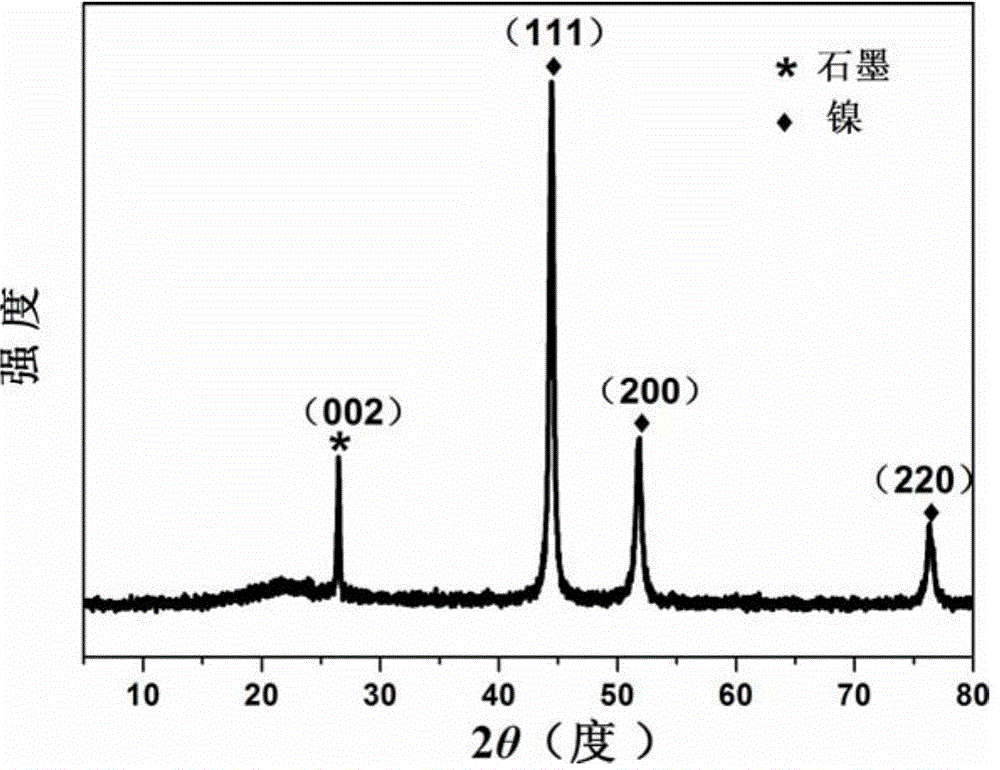

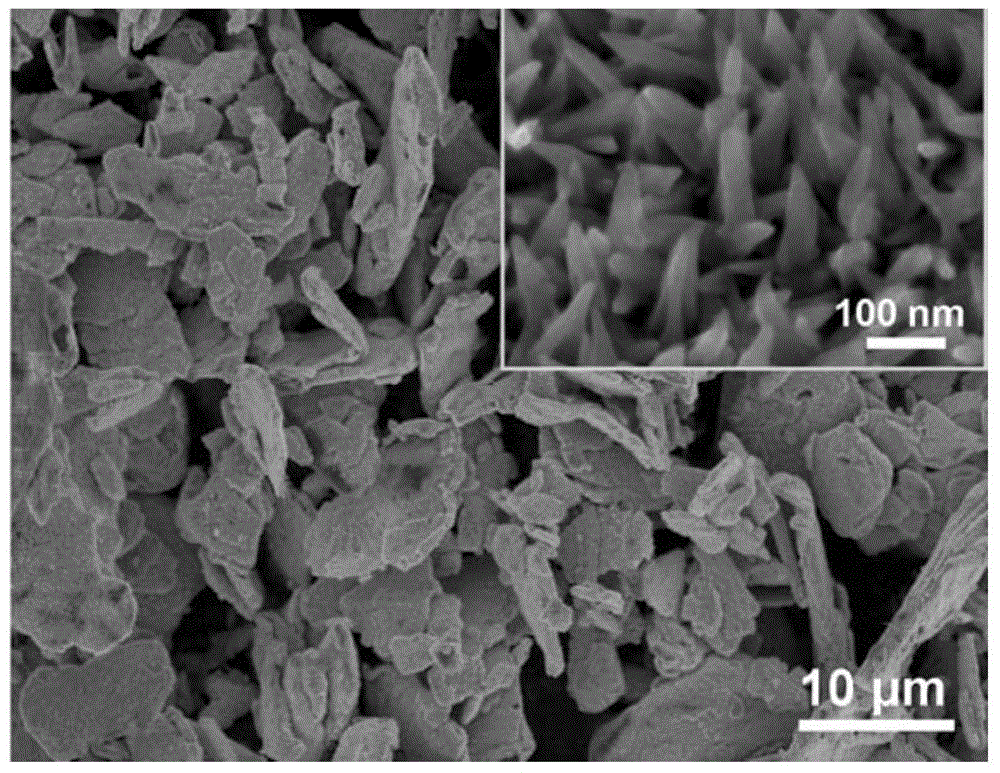

Embodiment 1

[0033] Using 200 mL of absolute ethanol as a solvent, 10 g of flake graphite particles were added to a 250 mL Soxhlet extractor and refluxed for 8 hours, filtered and dried in vacuum until use. Put the cleaned and dried graphite particles into the nickel sulfate solution to absorb for 12h, filter and dry for later use; then take the above graphite particles and put them in the ethanol solution of sodium borohydride and let stand, after the graphite particles and the ethanol solution are separated, filter and dry for later use . Separately prepare a solution, take 2.63g nickel sulfate hexahydrate, 25.4g potassium sodium tartrate tetrahydrate, 0.27g sodium hydroxide, 5.2mL 85% hydrazine hydrate solution to make 100mL solution; put 100mL solution into a three-necked flask and heat to 90 At ℃, add 0.5g of pre-treated graphite and react for 0.5h. Filter by suction, wash with deionized water twice, dry completely in a vacuum drying oven, and get image 3 The nano-shaped needle nicke...

Embodiment 2

[0039] Using 200 mL of absolute ethanol as a solvent, 10 g of flake graphite particles were added to a 250 mL Soxhlet extractor and refluxed for 8 hours, filtered and dried in vacuum until use. Put the cleaned and dried graphite particles into the nickel sulfate solution to absorb for 12h, filter and dry for later use; then take the above graphite particles and put them in the ethanol solution of sodium borohydride and let stand, after the graphite particles and the ethanol solution are separated, filter and dry for later use . Prepare another solution, take 5.25g nickel sulfate hexahydrate, 28.2g sodium potassium tartrate tetrahydrate, 0.4g sodium hydroxide, 22mL 85% hydrazine hydrate solution to make 200mL solution; put 200mL solution into a three-necked flask and heat to 80℃ , Add 0.5g of pre-treated graphite and react for 0.5h. Filter by suction, wash with deionized water twice, dry completely in a vacuum drying oven, and get image 3 The nano-shaped needle nickel-coated g...

Embodiment 3

[0042] Using 200 mL of absolute ethanol as a solvent, 10 g of flake graphite particles were added to a 250 mL Soxhlet extractor and refluxed for 8 hours, filtered and dried in vacuum until use. Put the cleaned and dried graphite particles into the nickel sulfate solution to absorb for 12h, filter and dry for later use; then take the above graphite particles and put them in the ethanol solution of sodium borohydride and let stand, after the graphite particles and the ethanol solution are separated, filter and dry for later use . Prepare a solution separately, take 7.88g nickel sulfate hexahydrate, 98.5g potassium sodium tartrate tetrahydrate, 1.8g sodium hydroxide, 21mL 85% hydrazine hydrate solution to make 300mL solution; put 300mL solution into a three-necked flask and heat to 70℃ , Add 0.5g of pre-treated graphite and react for 0.5h. Filter by suction, wash with deionized water twice, dry completely in a vacuum drying oven, and get Figure 4 The nano-shaped needle nickel-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com