A kind of manufacturing method of ultra-thick copper circuit board BGA

A manufacturing method and circuit board technology, applied in the direction of electrical connection formation of printed components, etc., can solve problems such as easy-to-break drill bits, excessive total copper thickness, and small drill hole diameter, so as to avoid easy-to-break drill bits and solve drilling processing problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiment of the present invention provides a method for manufacturing an ultra-thick copper circuit board BGA, adopting the design idea of local copper reduction, which can avoid drill breakage and solve the problem of drilling processing for ultra-thick copper circuit board BGA in the prior art. A detailed description will be given below in conjunction with the accompanying drawings.

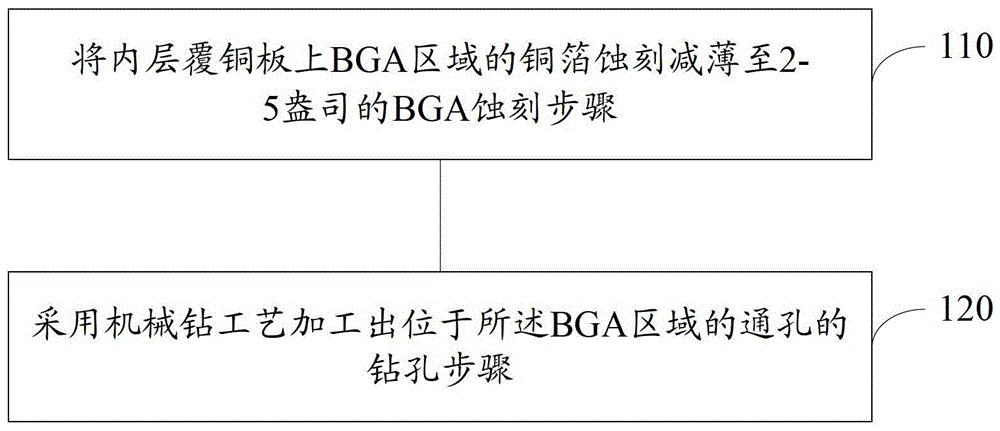

[0010] Please refer to figure 1 , the embodiment of the present invention provides a method for manufacturing an ultra-thick copper circuit board BGA, comprising:

[0011] 110. A BGA etching step for thinning the copper foil in the BGA area on the inner layer copper clad board to 2-5 ounces.

[0012] Generally, the copper thickness of each layer of the so-called ultra-thick copper circuit board BGA is ≥ 10 ounces. In the PCB manufacturing process of this embodiment, before the lamination step, the inner copper clad laminate is firstly processed, and the copper foil in the BGA a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com