Double power head derrick and full hydraulic double power head casing drilling rig

A dual power head and power head technology, applied in the field of drilling machinery, can solve the problems of low drilling efficiency and prone to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

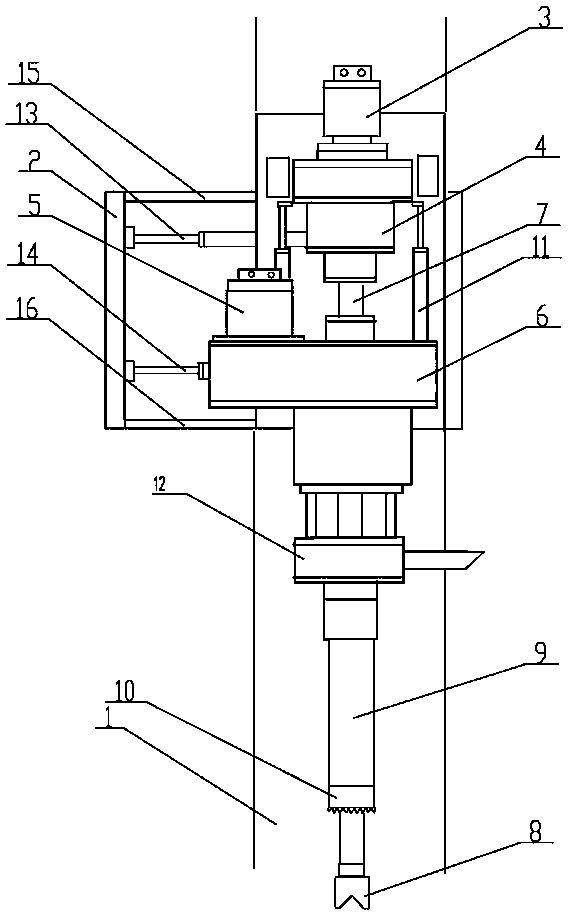

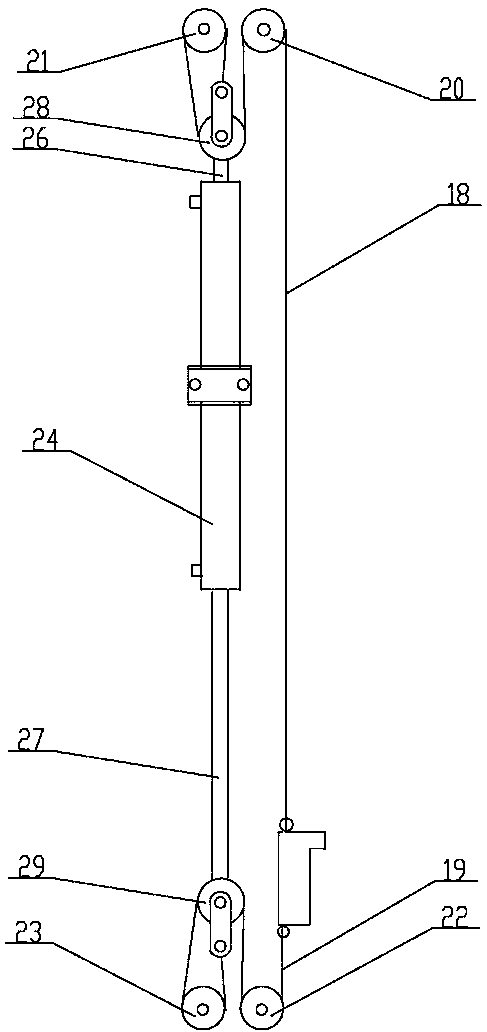

[0023] Embodiment one: as attached figure 1 , 2 As shown, the double power head derrick includes a column 1, a carriage 2 that can slide along the column 1, and the carriage 2 is provided with a first hydraulic motor 3, a first power head 4, a second hydraulic motor 5 and a second power head 6. The output shaft of the first hydraulic motor 3 is connected to the input shaft of the first power head 4, the inner drill rod 7 is installed on the first power head 4, and the inner drill bit 8 is installed at the lower end of the inner drill rod 7; the second hydraulic motor The output shaft of 5 is connected with the input shaft of the second power head 6, and an outer casing 9 is installed on the second power head 6, and a casing drill bit 10 is installed at the lower end of the outer casing 9, and the outer casing 9 is positioned at the outside of the inner drill rod 7. as attached figure 1 , 2 As shown, the above-mentioned double power head derrick also includes a mobile cylind...

Embodiment 2

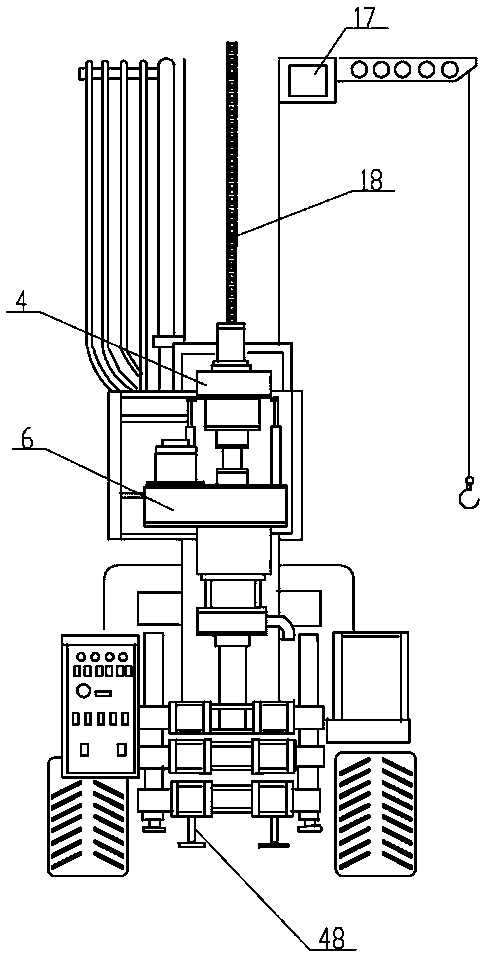

[0028] Embodiment two: as attached image 3 , 4 , 5, the present invention also provides a fully hydraulic double power head casing drilling rig, including the double power head derrick in Embodiment 1, and also includes a chassis 30, which is provided with a power transmission system and a hydraulic system, and the dual power The lower end of the head derrick is hinged on the chassis 30, and the derrick lifting and lowering cylinder 32 is hinged on the chassis 30. The other end of the derrick lifting and lowering cylinder 32 is hinged to the lower part of the double power head derrick, and the output end of the power transmission system is connected to the input end of the hydraulic system. Connection, the output end of the hydraulic system is connected with the double power head derrick.

[0029] as attached image 3 , 4 , 5, above-mentioned power transmission system comprises engine 33, speed changer 34, power take-off 35, transfer case 36, transfer case 37, the output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com