Method for preparing super capacitor carbon electrode material by using pistachio nut shell as raw materials

A technology of supercapacitors and pistachio shells, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of no discovery, achieve large micropore specific surface area, good application prospects, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

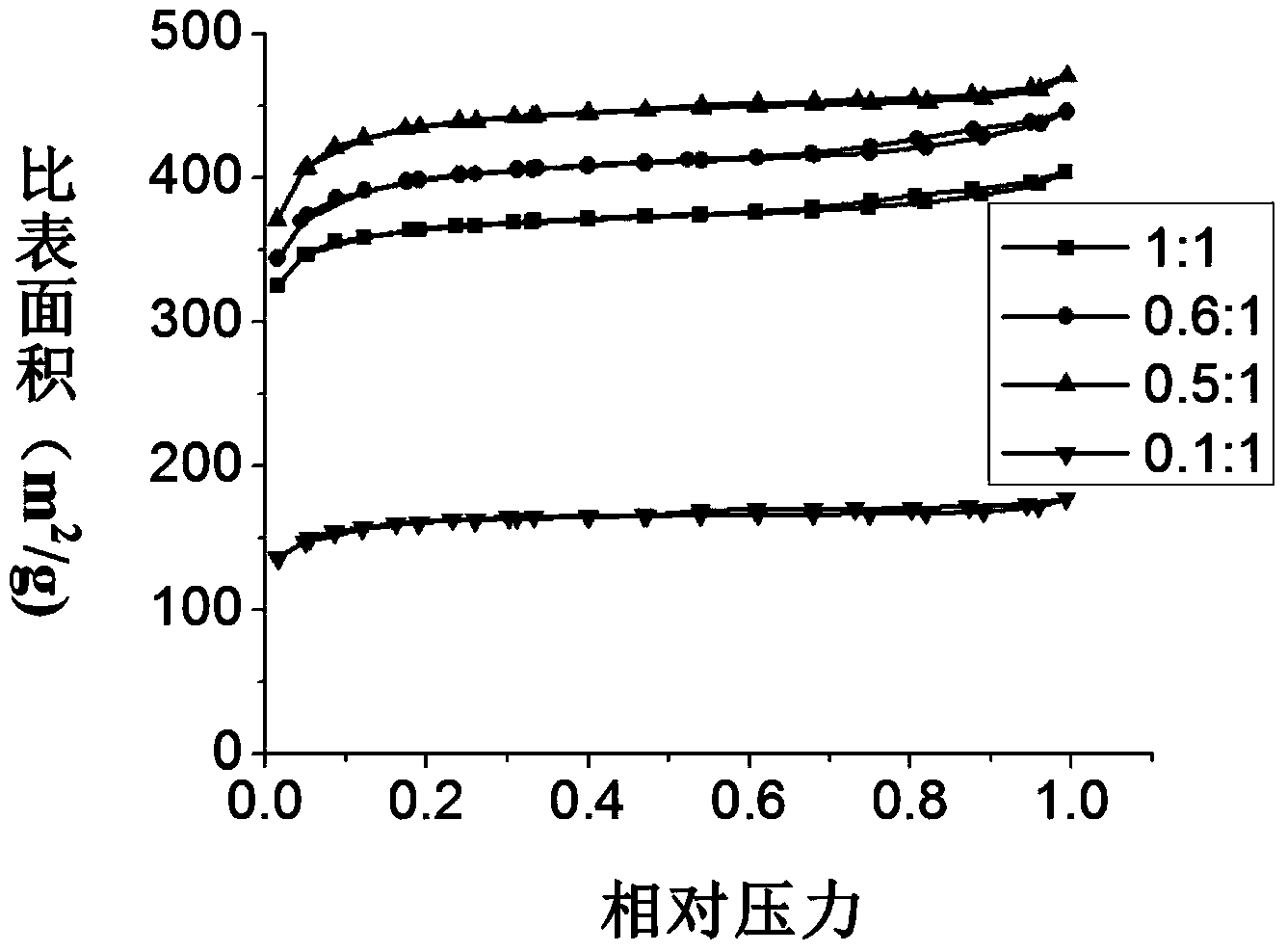

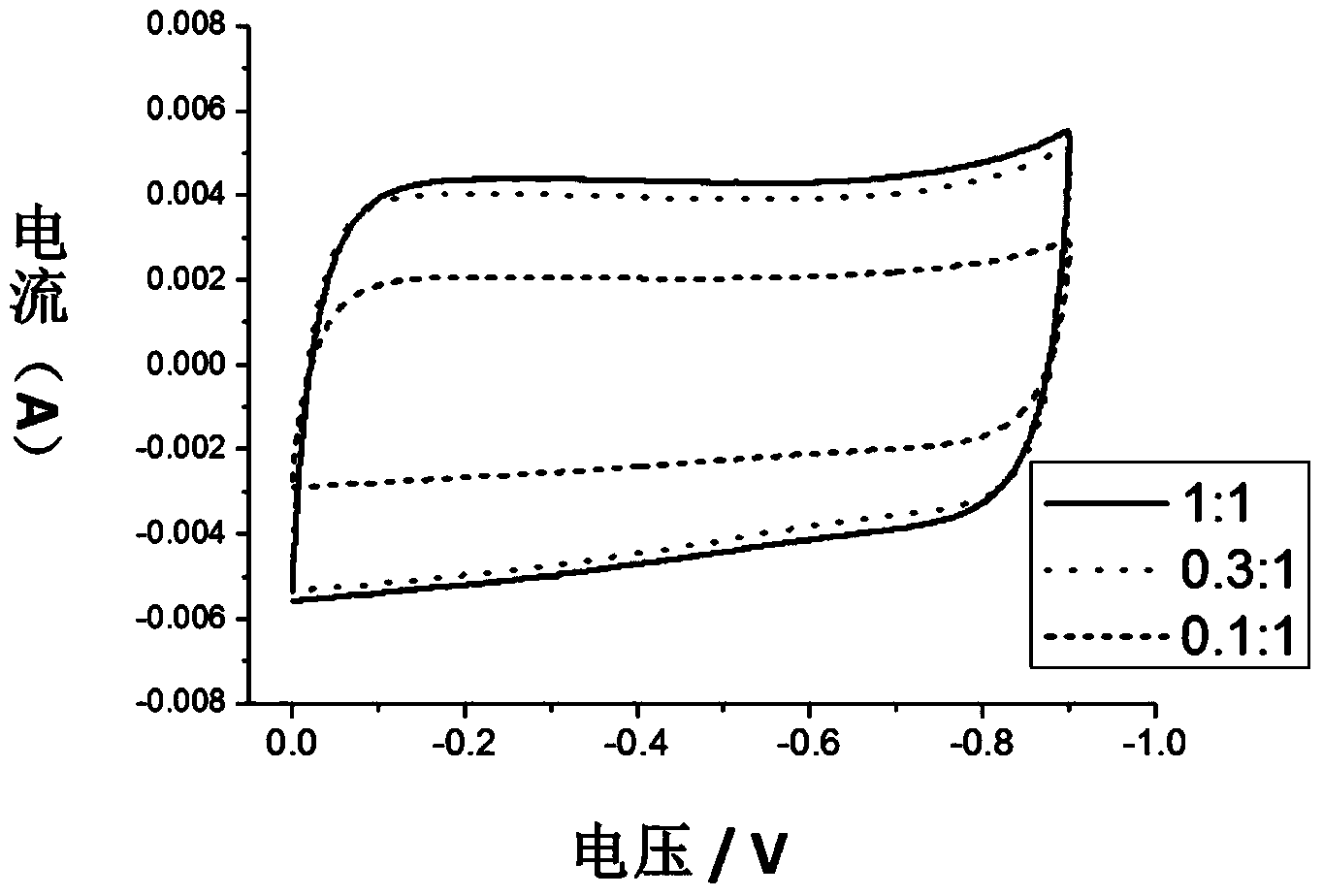

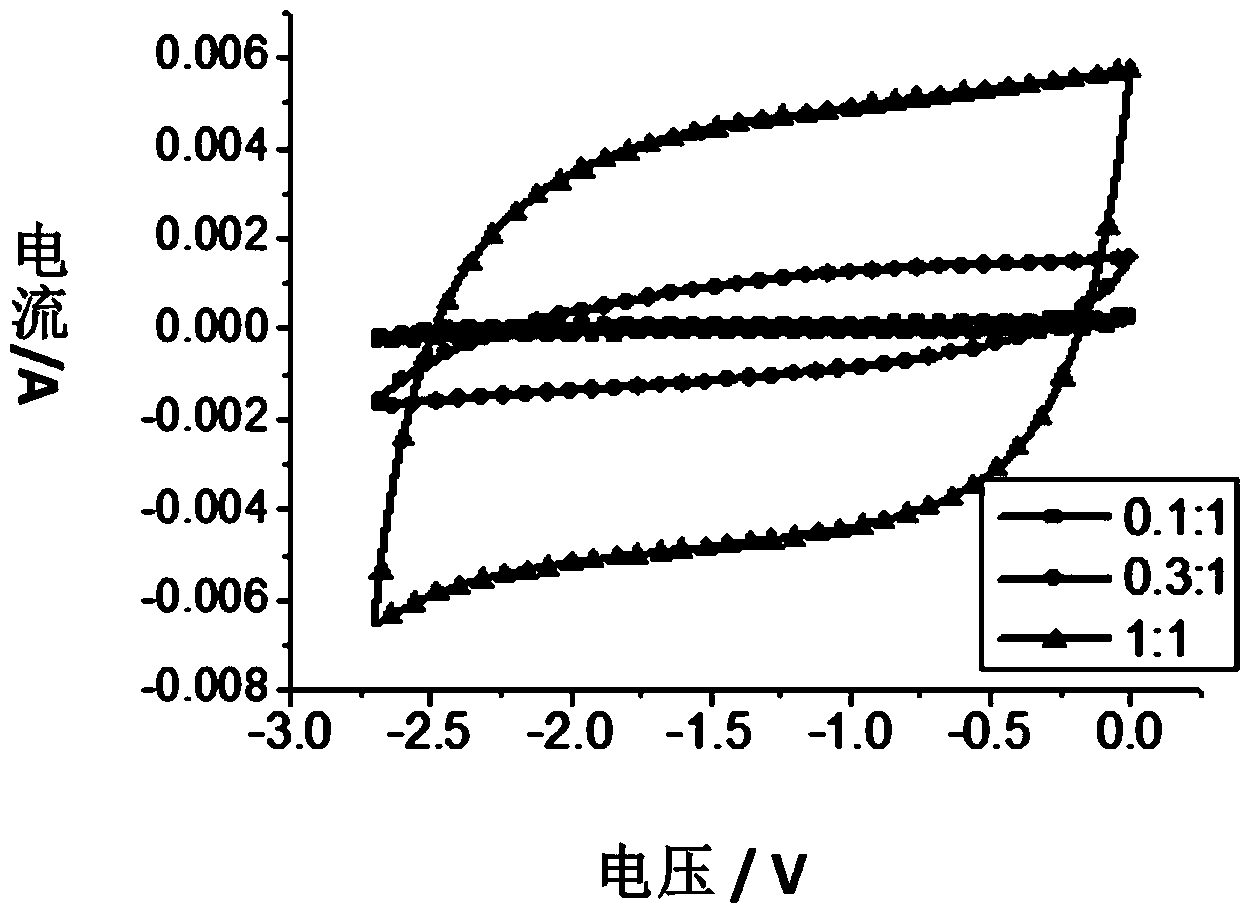

Embodiment 1

[0021] Mix 10 g dried and crushed pistachio shells, 1 g KOH, and 10 mL water evenly, place in a tube furnace, and then 2 Under protection, the temperature was raised to 600°C for carbonization for 4 hours. Subsequently, the obtained carbonized product is washed once with dilute hydrochloric acid, then washed with distilled water until neutral, and finally dried to obtain a carbon electrode material. N 2 Adsorption / desorption tests found that the product had a specific surface area of 300 m 2 / g, total pore volume 0.3 cm 3 / g. When the discharge current was 0.1 A / g, the specific capacitance value of the obtained carbon electrode material was 120 F / g in KOH electrolyte and 20 F / g in organic electrolyte.

Embodiment 2

[0023] Mix 10 g dried and crushed pistachio shells, 3 g KOH, and 10 mL water evenly, place in a tube furnace, and then 2 Under protection, the temperature was raised to 700°C for carbonization for 4 hours. Subsequently, the obtained carbonized product is washed once with dilute hydrochloric acid, then washed with distilled water until neutral, and finally dried to obtain a carbon electrode material. N 2 Adsorption / desorption tests found that the product had a specific surface area of 1000 m 2 / g, total pore volume 1.1 cm 3 / g. When the discharge current was 0.1 A / g, the specific capacitance value of the obtained carbon electrode material was 200 F / g in KOH electrolyte and 80 F / g in organic electrolyte.

Embodiment 3

[0025] Mix 10 g dried and crushed pistachio shells, 3 g NaOH, and 10 mL water evenly, place in a tube furnace, and then 2 Under protection, the temperature was raised to 600°C for carbonization for 4 hours. Subsequently, the obtained carbonized product is washed once with dilute hydrochloric acid, then washed with distilled water until neutral, and finally dried to obtain a carbon electrode material. N 2 Adsorption / desorption tests found that the product had a specific surface area of 700 m 2 / g, total pore volume 0.8 cm 3 / g. When the discharge current was 0.1 A / g, the specific capacitance of the obtained carbon electrode material was 180 F / g in KOH electrolyte and 53 F / g in organic electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com