a transmission cable

A transmission cable and steel wire rope technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor oil resistance, large change rate of tensile strength and elongation at break, etc., and achieve good resistance, tensile strength and elongation at break The elongation change rate is small and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

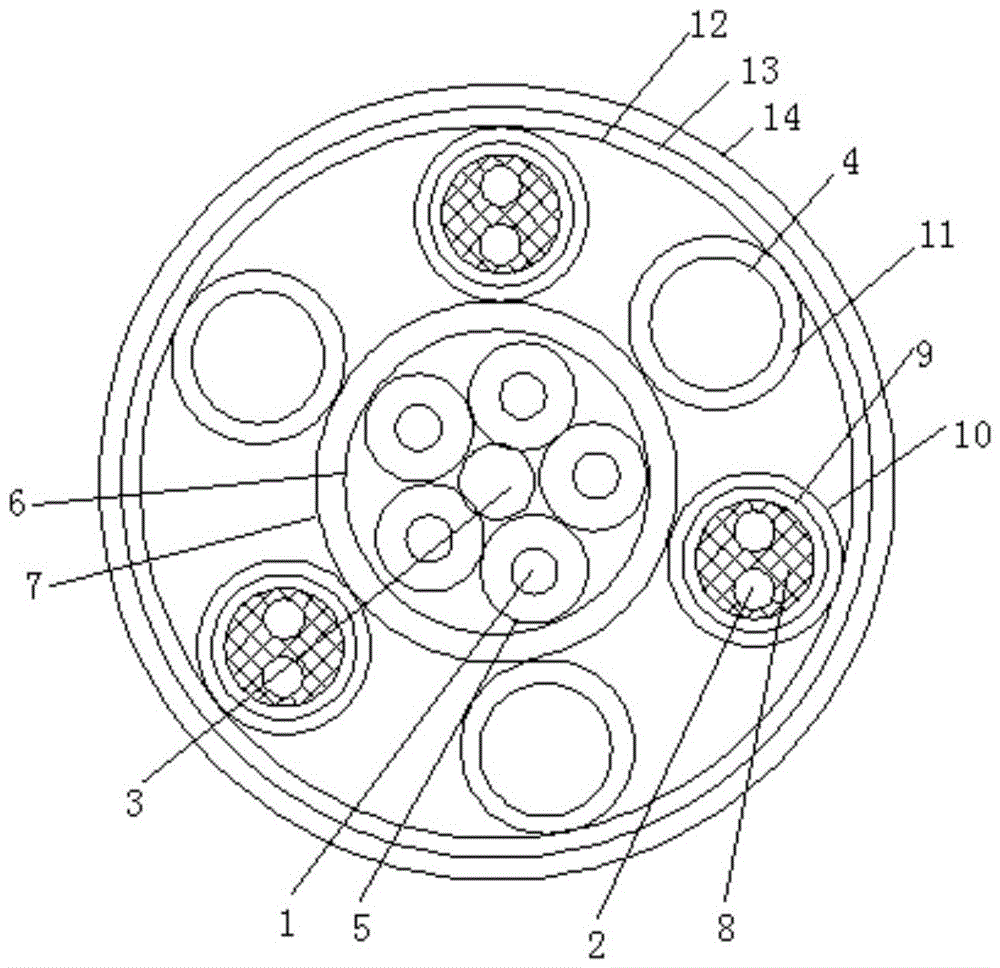

[0013] Such as figure 1 As shown, a transmission cable includes a main conductor 1, a control conductor 2, an elastic tube 3 and a steel wire rope 4, and a polyperfluoroethylene insulating layer 5 is coated on the outside of the main conductor 1, surrounding a plurality of main conductors 1 The outer side of the elastic tube 3 is covered successively with an aluminum foil wrapping layer 6 and a galvanized steel wire braided shielding layer 7 to form the main core. Coated with calcined mica tape wrapping layer 9 and tinned annealed copper wire plus polyester wire braided insulation shielding layer 10 to form the control wire core in turn, coated with waterproof glue 11 on the outside of the steel wire rope 4, the multiple steel wire ropes 4 and the control wire core are uniformly Distributed on the outer side of the main wire core and covered with a waterproof canvas wrapping layer 12, a glass fiber fireproof layer 13 and an outer sheath 14 in sequence on the outer side.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com