Method for fitting material loss angle

A technology for fitting materials and loss angles, which is applied in the field of electronics, can solve the problems of such parameter changes, and achieve the effects of small error, strong practicability, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method for fitting the material loss angle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The specific implementation process of this method for fitting material loss angle is as follows:

[0015] First, a small test board needs to be added to the designed single board.

[0016] Then test the test board to get the impedance diagram and loss diagram and the results.

[0017] Then physically slice the test board to obtain real board layer information.

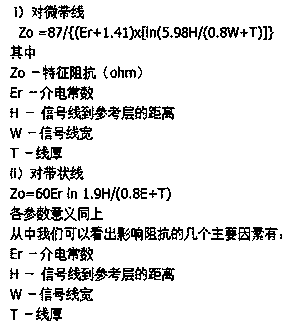

[0018] The dielectric constant of the material is calculated by the formula, the calculation formula is as attached figure 1 shown.

[0019] The loss angle is obtained by the simulation method, the transmission line model is established using the data of the physical slice, and the loss angle of the test is fitted, and the simulation data and the test data are fitted by continuously changing the loss angle until they are completely consistent, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com