Colored Photosensitive Resin Composition

A technology of photosensitive resin and composition, which is applied in optics, optical filters, optical mechanical equipment, etc., can solve problems that have not been raised, and achieve delamination suppression, high contrast ratio and light transmittance, suppression of impurities and Effect of Change in Viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

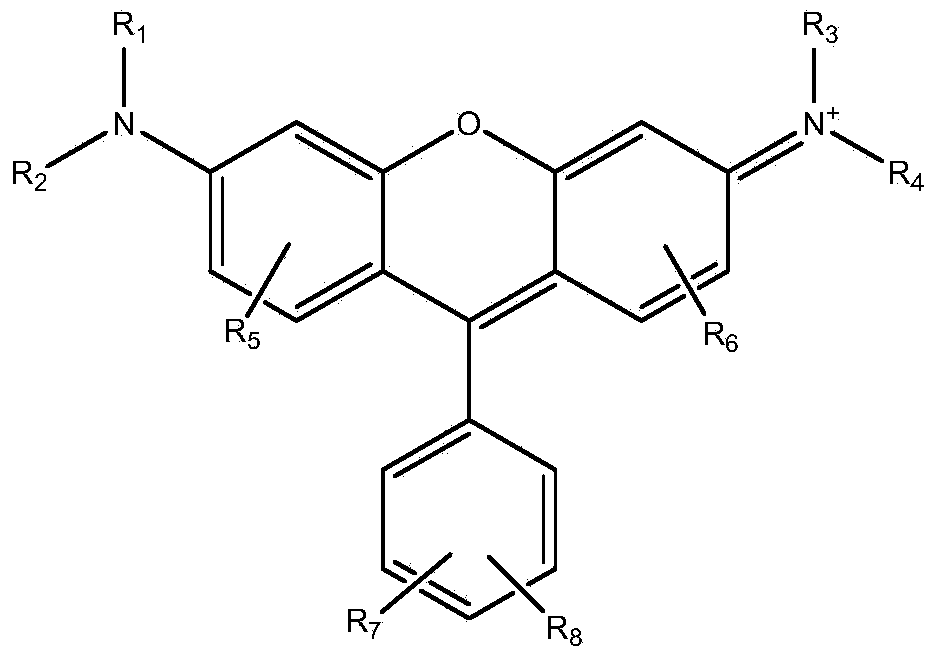

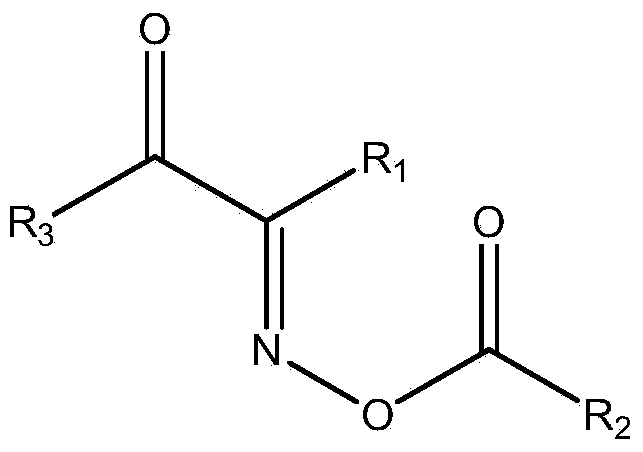

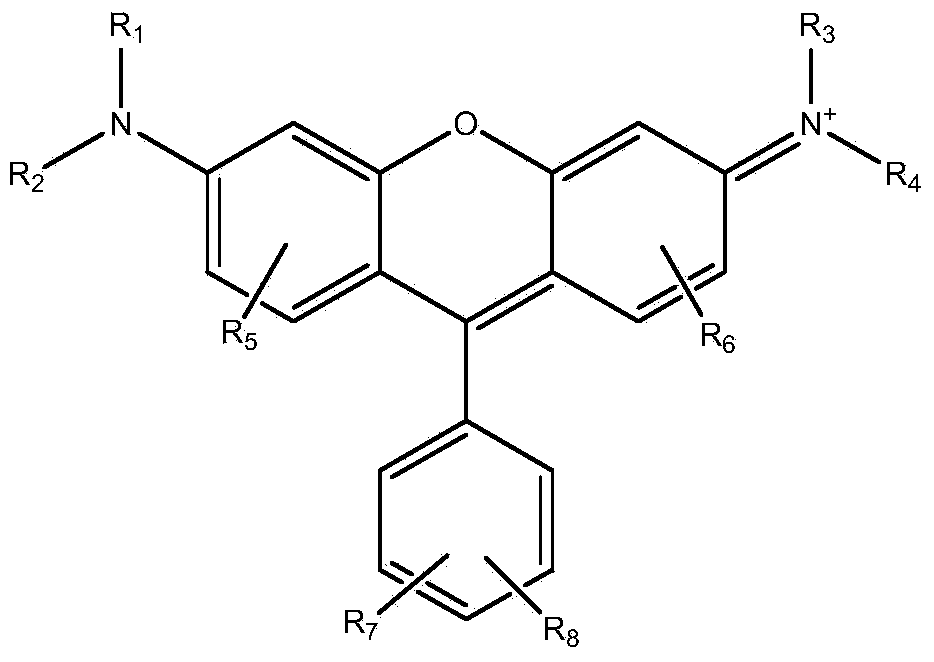

Method used

Image

Examples

preparation example Construction

[0064] An embodiment of the production method of the alkali-soluble resin will be described below.

[0065] Add the aforementioned monomer, the solvent relative to the monomer content of 0.5 to 20 times, and the polymerization initiator relative to the molar amount of the monomer of 0.1% to 10% to be equipped with a stirrer, a thermometer, a reflux cooling pipe, a titration device and Nitrogen was introduced into the flask in line and subsequently replaced with nitrogen. Then, it was stirred at 40°C to 140°C for 1 hour to 10 hours.

[0066] The above-mentioned solvent used herein can be any common solvent used for free radical polymerization, for example, it includes: selected from tetrahydrofuran, dioxane, dimethyl ethyl glycol, dimethyl ethyl diethylene glycol Alcohol, acetone, methyl ethyl ketone, methyl isobutyl ketone, cyclohexanone, ethyl acetate, butyl acetate, propylene glycol monomethyl ethyl acetate, 3-methoxybutyl acetate, methanol, Any of ethanol, propanol, n-but...

Embodiment 1

[0143] The colored photosensitive resin composition was prepared as follows: 39.8 parts of the colorant dispersion in Preparation Example 1, 11.1 parts of the synthetic resin in Synthesis Example 1, 3.7 parts of KAYARAD DPHA (manufactured by Nippon Chemical Co.), 0.8 parts of TR-PBG-305 (manufactured by TRONLY company), 34.6 parts of propylene glycol monomethyl ether acetate, and 10.0 parts of 4-hydroxy-4-methyl-2-pentanone.

Embodiment 2

[0145] The colored photosensitive resin composition was prepared as follows: 39.8 parts of the colorant dispersion in Preparation Example 1, 11.1 parts of the synthetic resin in Synthesis Example 1, 3.7 parts of KAYARAD DPHA (manufactured by Nippon Chemical Co.), 0.8 parts Parts of TR-PBG-305 (manufactured by TRONLY Corporation), 19.6 parts of propylene glycol monomethyl ether acetate, and 25 parts of 4-hydroxy-4-methyl-2-pentanone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com