Hot rolling workshop roof heat preservation structure and method

A technology for workshops and insulation boards, applied in the direction of roof coverings, building roofs, roof insulation materials, etc., can solve the problems of reducing strength, hidden dangers, aging of extruded boards, etc., to avoid equipment accidents, prolong service life, The effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The construction of this project needs to be started in spring and autumn when there is little rain to avoid adverse impacts caused by rain.

[0032] 1) First remove the damaged SBS waterproof coiled material and thermal insulation extruded board, and remove the damaged extruded board and waterproof coiled material in high temperature areas such as rolling steel, air-drying platform, cooling bed, etc.;

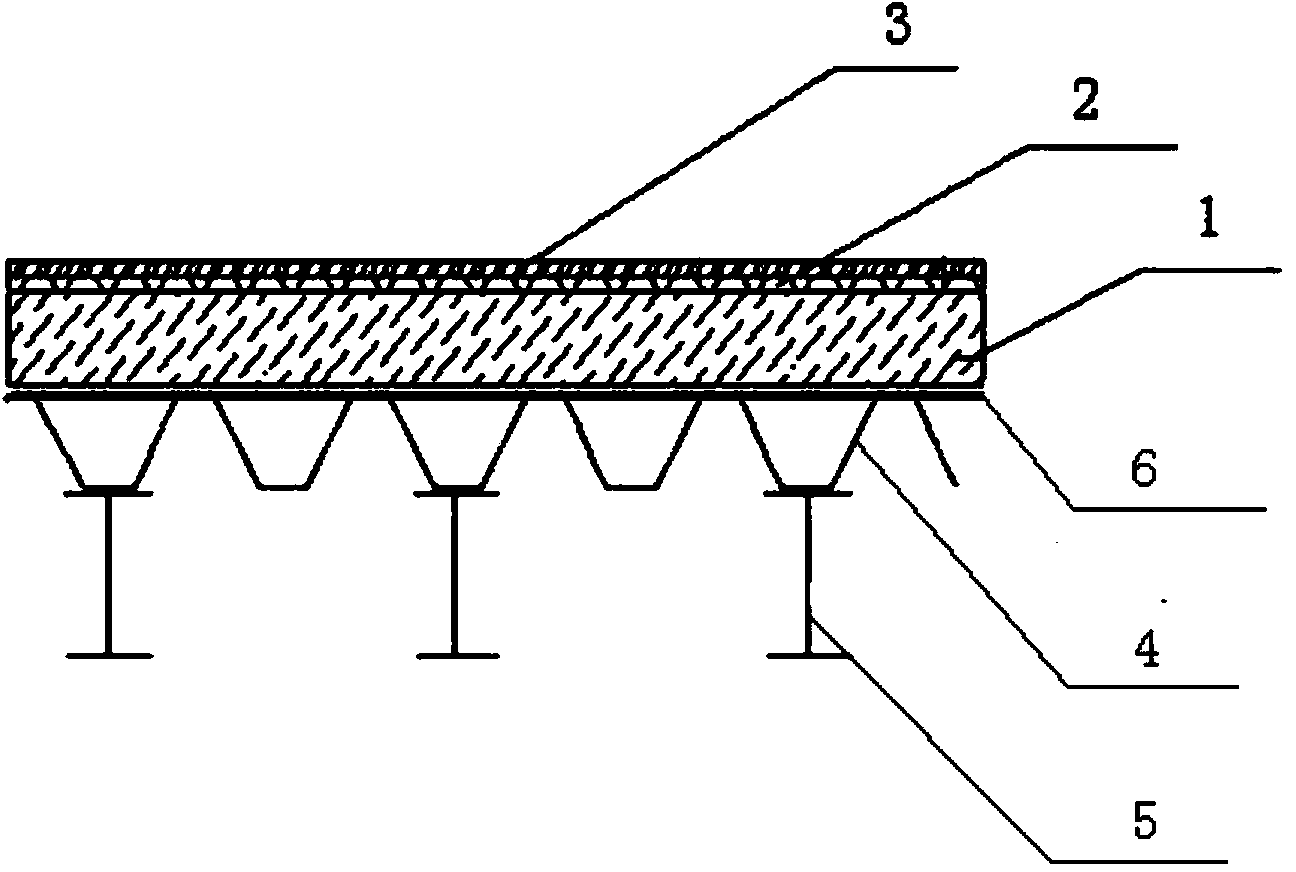

[0033] 2) The diamond-shaped steel mesh is fully paved on the color steel profiled plate, the thickness of the wire stem is 1.5mm, the width is 2.5mm, and the pitch is 40mm, which plays a supporting role and improves the compressive strength;

[0034] 3) The diamond-shaped steel mesh is covered with special rock wool with a thickness of 80mm. The upper and lower layers are overlapped with staggered seams. The edge of the rock wool board is placed in the middle of the rock wool board below. The size of the rock wool board is about 1200X500, so as to avoid the overlap bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com