Anti-blocking grouting nozzle

An anti-clogging and sprinkler technology, applied in construction, infrastructure engineering and other directions, can solve the problems of project progress and quality impact, grouting pipe clogging accident, unsatisfactory effect and other problems, and achieve good construction quality, good anti-clogging performance and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

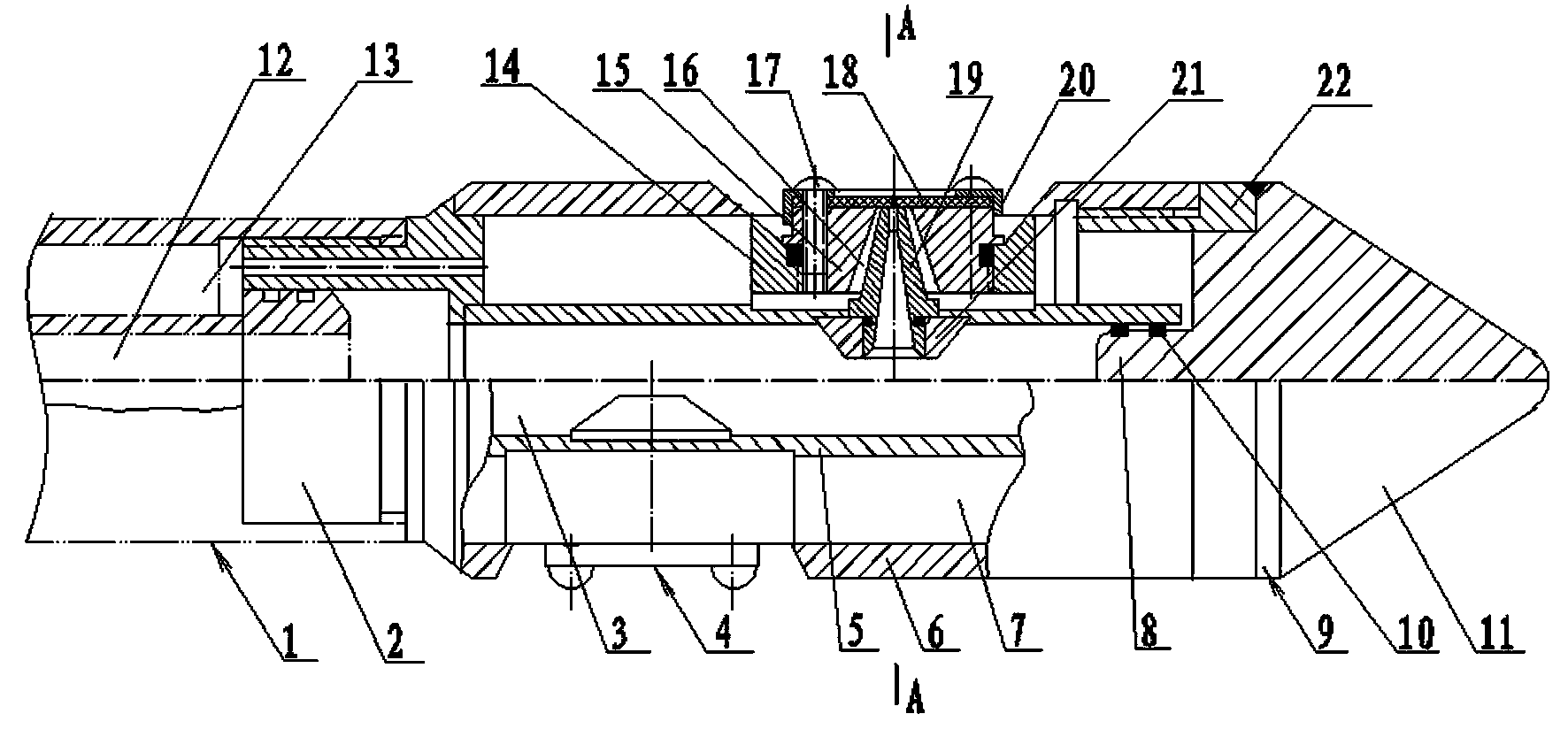

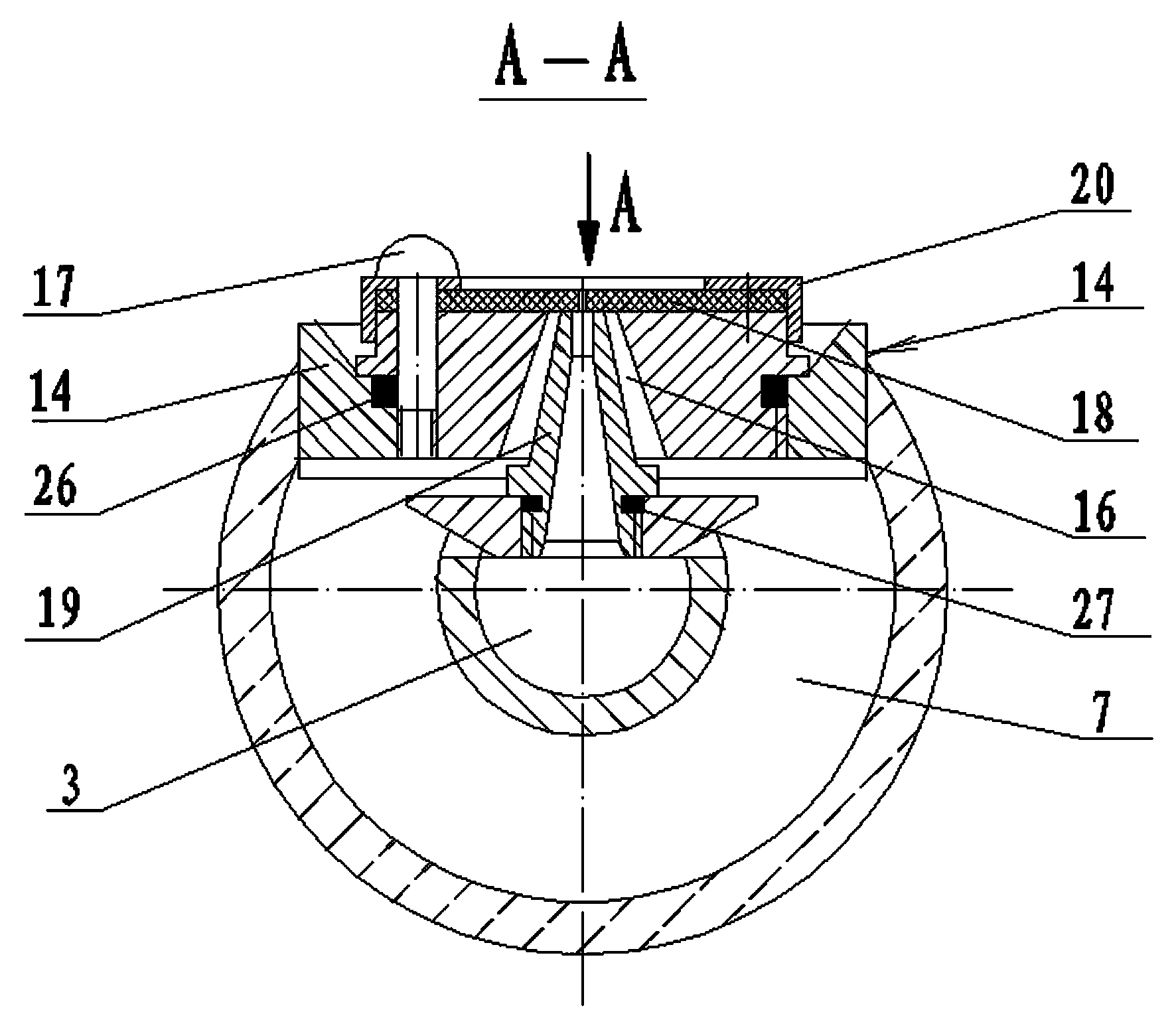

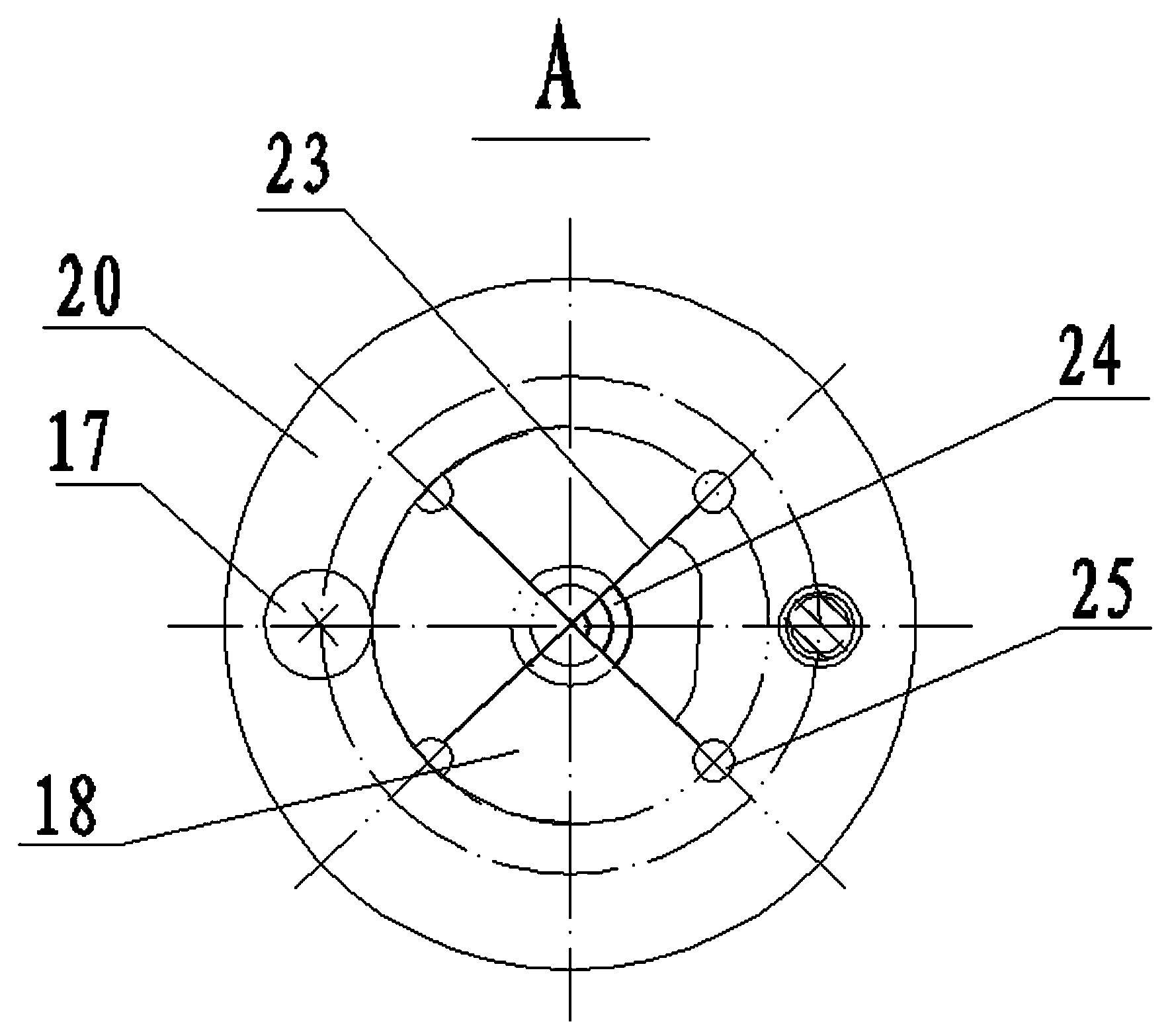

[0012] The anti-clogging grouting nozzle includes a nozzle assembly 4, an inner pipe 5, an outer pipe 6, a cone head 9, and a handle 2. The handle 2 is connected to the grouting pipe 1 through an external thread at one end, and the other end is welded with the inner pipe 5 and the outer pipe 6 of the same longitudinal axis. The air passage 13 communicates with the annular air passage 7 between the inner and outer pipes. The cone head 9 is welded by a cone body 11 with a mandrel 8 at one end and a 60° cone at the other end and a threaded sleeve 22. Seal with the mandrel sealing ring 10. The nozzle assembly 4 is composed of a nozzle 19 , a nozzle seat 21 , an air nozzle 15 , an air nozzle seat 14 , a valve 18 and a gland 20 . The nozzle 19 is an injection nozzle with a tapered passage inside. The nozzle 19 is connected with the nozzle seat 21 by coaxial threads and sealed with the nozzle sealing ring 27. The interior of the gas nozzle 15 matches the tapered outer circle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com