Nanocrystalline metal oxide with p-n composite structure, preparation method and application of nanocrystalline metal oxide

A composite structure, nano-metal technology, applied in the direction of textiles and papermaking, fiber chemical characteristics, artificial filaments of inorganic raw materials, etc., can solve the problems of long reaction time, achieve high sensitivity, improve low sensitivity, and be easy to promote.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Accurately weigh 2.6080g of cobalt acetate and dissolve it in 10mL of DMF, stir for 2 hours, then add 0.500g of stannous chloride, continue to stir until completely dissolved, slowly add 1.5g of PVP, continue to stir for 4 hours, pour the obtained dark blue solution into In the syringe, the static voltage is 20kV, and the advancing speed is 0.0006mm·s- 1 , The spinning was carried out under the condition that the plate spacing was 20 cm. Dry the tin foil paper with the product at room temperature for 12 hours, then collect the product and place the product in a muffle furnace, heat up at a rate of 5°C / min, and bake at 500°C for 2 hours to obtain n-SnO 2 p-Co 3 o 4 product.

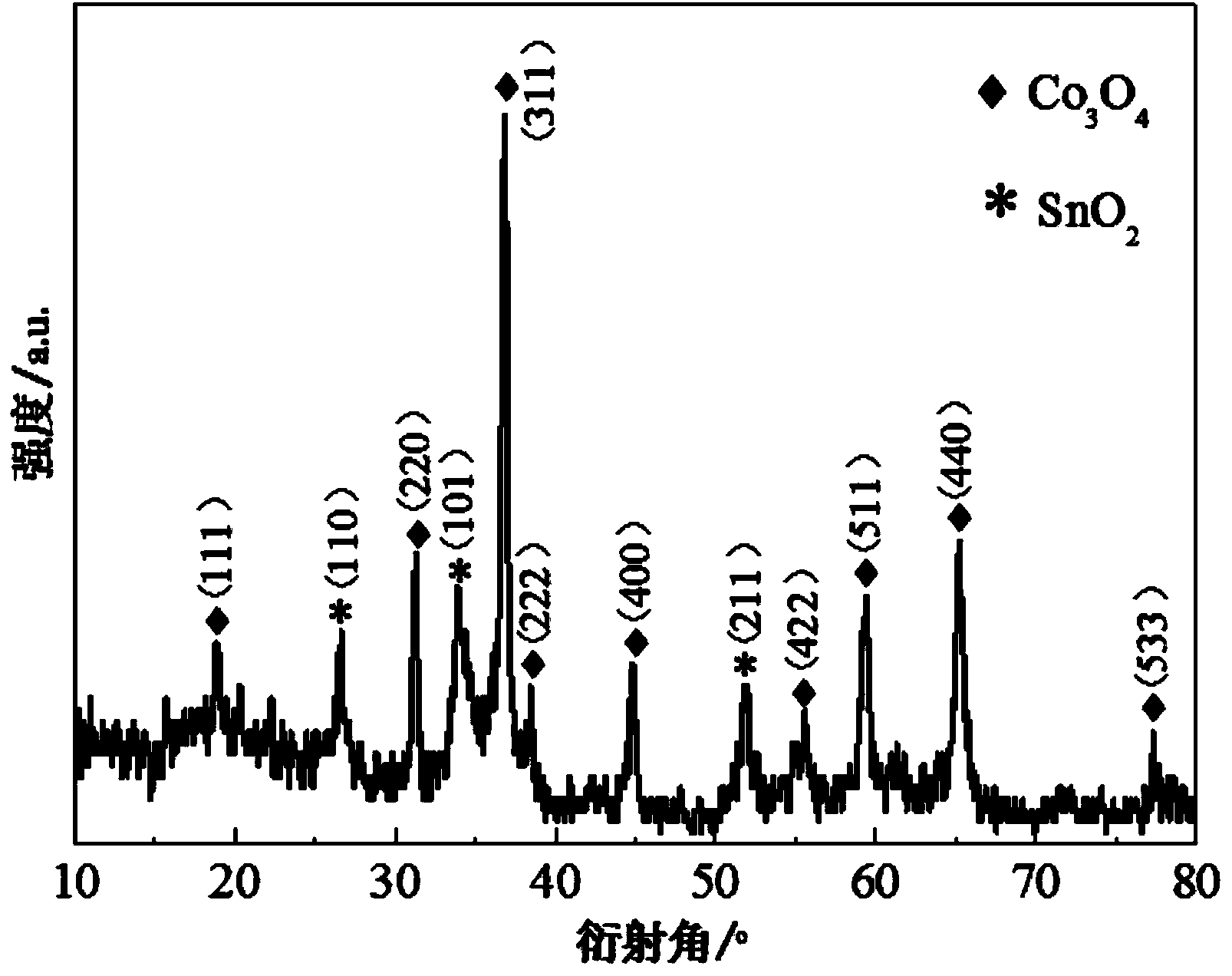

[0026] The scanning electron microscopy results of the figure 1 and figure 2 , n-SnO before calcination 2 p-Co 3 o 4 The diameter of the nanofiber is 200-300nm, and the diameter of the n-SnO2p-Co3O4 nanofiber is shortened to about 150nm after calcination, and it is composed of nanoparticles...

Embodiment 2

[0028] Accurately weigh 1.3040g of cobalt nitrate and dissolve it in 7mL of DMF, stir for 4 hours, then add 0.100g of tin chloride, continue stirring until completely dissolved, then slowly add 0.8g of PVA, continue stirring for 6 hours, then pour the obtained dark blue solution into a syringe , at a static voltage of 18kV and a propulsion speed of 0.0006mm·s -1 , Spinning was carried out under the condition that the plate spacing was 18 cm. Dry the tinfoil paper with the product at room temperature for 24 hours, then collect the product and place it in a muffle furnace, heat up at a rate of 10°C / min, and bake at 500°C for 4 hours to obtain the n-SnO2p-Co3O4 product.

Embodiment 3

[0030] Accurately weigh 1.3040g of cobalt sulfate and dissolve it in 7mL of DMF, stir for 6 hours, then add 0.300g of tin chloride, continue stirring until completely dissolved, then slowly add 1.0g of PAM, continue stirring for 8 hours, then pour the obtained dark blue solution into a syringe , at a static voltage of 18kV and a propulsion speed of 0.0010mm·s -1 , The spinning was carried out under the condition that the plate spacing was 20 cm. Dry the tinfoil paper with the product at room temperature for 36 hours, then collect the product and place it in a muffle furnace, heat up at a rate of 5°C / min, and bake at 600°C for 2 hours to obtain the n-SnO2p-Co3O4 product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com