Wall coating and preparation method

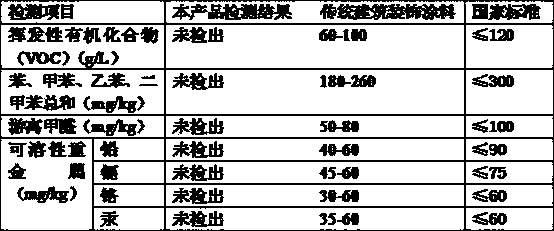

A paint and wall technology, applied in the field of wall paint and preparation, can solve the problems of poor environmental performance, high production cost, easy mold on the wall, etc., and achieve the effect of low production cost, low cost and good covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

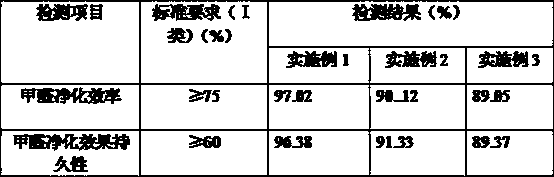

Embodiment 1

[0025] It is characterized in that the coating is composed of the following parts by weight:

[0026] Weigh 15kg of bamboo pulp, 30kg of rice straw pulp, and 15kg of rag pulp, mix them evenly, break them with a beating machine, add 300kg of water, dilute them into the reactor, add 1.5kg of defoamer, and rotate at 700-900 rpm Stir for 15 minutes under the conditions of, then add 100kg of titanium dioxide, 230kg of pure acrylic emulsion, and stir for 20-30 minutes under the condition of rotation speed of 500-1200 rpm, and then sand to the material fineness below 50um; Put 35kg vegetable gum composition, 1.5kg defoamer, 4kg plant extract into the reactor, stir for 15-30 minutes at 400-800 revolutions per minute; finally adjust with 1.5kg high alkalinity complex alkali The PH value is 6-7, and it is qualified product after passing through 200 mesh sieve, and it is packaged and stored.

[0027] Preparation of vegetable gum composition: weigh 35 kg of couma gum and 35 kg of stone gum an...

Embodiment 2

[0030] Weigh 15kg of bamboo pulp, 30kg of rice straw pulp, and 15kg of rag pulp, mix them evenly, break them with a beating machine, add 300kg of water, dilute them into the reactor, add 1.5kg of defoamer, and rotate at 700-900 rpm Stir for 15 minutes under the condition of, then add 100kg of titanium dioxide, 230kg of polyvinyl acetate latex liquid, stir for 20-30 minutes under the condition of rotation speed of 500-1200 revolutions per minute, and then sand to the material fineness below 50um ; 35kg of vegetable gum composition, 1.5kg of defoamer, 4kg of plant extract into the reactor, stirring at 400-800 revolutions per minute for 15-30 minutes; finally 1.5kg of high alkalinity complex alkali Adjust the PH value to 6-7 and pass the 200-mesh sieve to be a qualified product, which is packaged and stored.

[0031] Preparation of vegetable gum composition: weigh 35 kg of couma gum and 35 kg of stone gum and mix the two to obtain the vegetable gum composition. Among them, couma gu...

Embodiment 3

[0034] Weigh 10kg of bamboo pulp, 20kg of rice straw pulp, and 10kg of rag pulp, mix them evenly, break them with a beating machine, add 200kg of water and dilute them into the reactor, add 1kg of defoamer, and rotate at 700-900 rpm. Stir for 15 minutes; then add 70kg of titanium dioxide, 180kg of pure acrylic emulsion, and stir for 20-30 minutes at a speed of 500-1200 revolutions per minute, and then sand to the material fineness below 50um; 30kg of plant Put the glue composition, 1kg defoamer, 2kg plant extract into the reaction kettle, stir for 15-30 minutes under the condition of 400-800 revolutions per minute; finally adjust the PH value to 6 with 1kg high alkalinity compound alkali -7. After passing through a 200-mesh sieve, it is a qualified product, which is packaged and stored.

[0035] Preparation of the vegetable gum composition: weigh 30 kg of couma gum and 30 kg of stone gum, and mix the two to obtain the vegetable gum composition. Among them, couma gum and stone fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com