A special coating for interior walls and its preparation method

A technology for coatings and interior walls, applied in the direction of coatings, etc., can solve the problems of special mold growth on interior walls, unfavorable human health, and no clear instructions, etc., and achieve the goals of shortening the pigment dispersion system, good environmental protection functions, and improving leveling performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

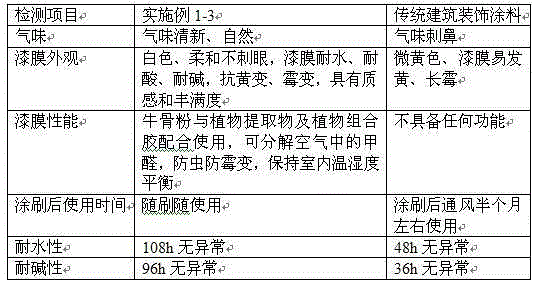

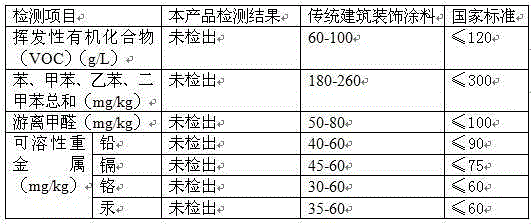

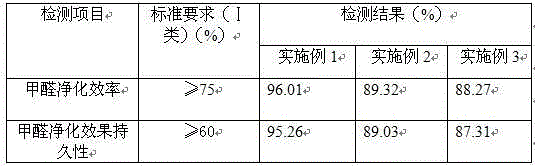

Examples

Embodiment 1

[0025] Add 180kg of water, 2kg of berberine, 2kg of D-504 wetting agent, 4kg of dispersant, and 1.5kg of defoamer into the reactor, and disperse for 30 minutes at a speed of 700-900 rpm; then add 200kg of titanium dioxide, 80kg of calcium carbonate powder, and 70kg of bovine bone powder are stirred for 20-30 minutes at a speed of 500-1200 rpm, and sand-milled until the fineness of the material is below 50um; then add 200kg of pure acrylic acid Emulsion, 30kg vegetable gum composition, 3kg75% ethanol, 1.5kg defoamer, 4kg plant extract are put into the reaction kettle, and stirred for 15-30 minutes under the condition of rotating speed of 400-800 rpm; finally, 10kg of The vegetable gum composition and 70kg of water adjust the viscosity so that the viscosity at room temperature is (90-110) KU, and after passing through a 200-mesh sieve, it is a qualified product, which is packaged and preserved.

[0026] Preparation of the vegetable gum composition: weigh 20 kg of flax gum and 20...

Embodiment 2

[0029] Add 200kg of water, 3kg of berberine, 2.5kg of D-504 wetting agent, 3.8kg of dispersant, and 2kg of defoamer into the reactor, and disperse for 30 minutes at a speed of 700-900 rpm; Add 150.6kg of titanium dioxide, 50.2kg of calcium carbonate powder, and 98.5kg of bovine bone powder, stir for 20-30 minutes at a speed of 500-1200 rpm, and grind until the fineness of the material is below 50um; then add Put 151.2kg of pure acrylic emulsion, 34kg of vegetable gum composition, 2.1kg of 75% ethanol, 2kg of defoamer, and 5kg of plant extract into the reactor, and stir for 15-30 minutes at a speed of 400-800 rpm ; Finally, adjust the viscosity with 10kg of vegetable gum composition and 80kg of water, so that the viscosity at normal temperature is (90-110) KU, after passing through a 200-mesh sieve, it is a qualified product, and it is packaged and preserved.

[0030] Preparation of the vegetable gum composition: weigh 22 kg of flax gum and 22 kg of carrageenan, and mix the two...

Embodiment 3

[0033] Add 150kg of water, 1kg of berberine, 1kg of D-504 wetting agent, 2kg of dispersant, and 1kg of defoamer into the reactor, and disperse for 30 minutes at a speed of 700-900 rpm; then add 250kg Titanium dioxide, 100kg of calcium carbonate powder, 50.1kg of bovine bone powder, stirring for 20-30 minutes under the condition of rotating speed of 500-1200 rpm, and sand milling until the fineness of the material is below 50um; then add 248.9kg of pure Acrylic emulsion, 15kg plant gum composition, 4kg75% ethanol, 1kg defoamer, 3kg plant extract are put into the reaction kettle, and stirred for 15-30 minutes under the condition that the rotation speed is 400-800 rpm; The vegetable gum composition and 50kg of water adjust the viscosity so that the viscosity at room temperature is (90-110) KU, and after passing through a 200-mesh sieve, it is a qualified product, which is packaged and preserved.

[0034] Preparation of the vegetable gum composition: weigh 10 kg of flax gum and 10 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com