Polyvinyl alcohol composite foam material and preparation method thereof

A polyvinyl alcohol and composite foam technology, applied in the field of nanomaterials, can solve the problems of volume reduction, disappearance, and no foam, and achieve the effects of reducing water absorption, improving mechanical properties, and strong compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of Nanofiber Suspension

[0027] method one

[0028] (1) Shearing and boiling: Take 5g of paper (the composition is cellulose) and use medical scissors to cut the raw material into pieces (with a diameter less than 1mm) and put it into a three-neck flask, add 95mL of deionized water, and boil for 1 hour to obtain a slurry.

[0029] (2) Grinding: After cooling the slurry, pour it into a wet mill and grind it once (gear spacing: 0.5 μm), 2 minutes each time.

[0030] (3) Soaking and ultrasonic dispersion: Add deionized water to the milled slurry to make the mass fraction of nanofibers 5%, soak for 1 hour, and ultrasonicate twice (ultrasonic frequency 2000H z ), 2 minutes each time.

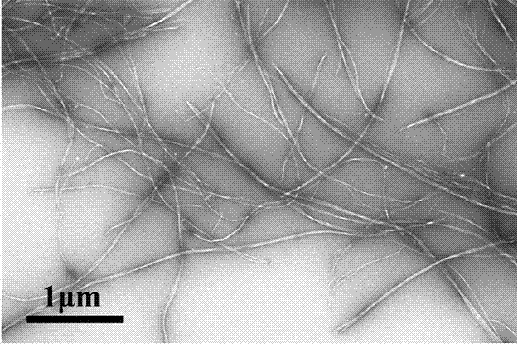

[0031] (4) High-pressure homogenization: The slurry obtained after the treatment in step (3) passes through the high-pressure homogenizer 20 times at a rate of 50ml / min at 150MPa to obtain a suspension of nanofibers, wherein the length of the nanofibers is 12- 20μm, ...

Embodiment 2

[0042] The preparation of embodiment 2 polyvinyl alcohol solution

[0043] Weigh 5g of polyvinyl alcohol (PVA) powder and place it in a three-neck flask, add 45-495mL of deionized water, and stir at 80-100°C for 0.5-3 hours at a stirring speed of 60-500r / min until completely dissolved to obtain the mass The PVA solution with a fraction of 1%-10% should be cooled and stored at low temperature (1-4°C).

Embodiment 3

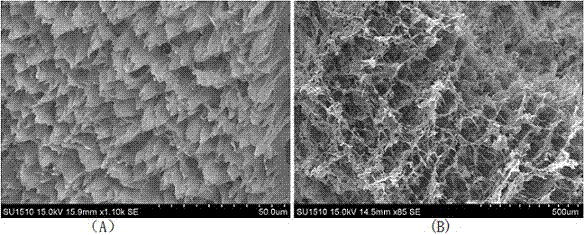

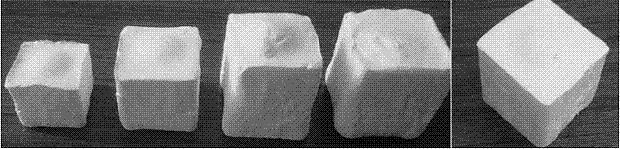

[0045] Weigh the PVA solution (containing 0.8g polyvinyl alcohol) in Example 2, place it in a three-necked flask, and add the nanofiber suspension (containing 1.2g nanofibers) in Example 1 to the three-necked flask under the condition of mechanical stirring. While stirring, the temperature was raised to 80° C., and the water was evaporated until the mass of the remaining part was 40 g. Then pour the remaining part into a petri dish to cool, place it at 1-4°C for 2 days, then freeze it in a low-temperature refrigerator at -78°C for 1 day, take it out and freeze-dry it in a freeze dryer for 24 hours to obtain foam material 3. The mass percentage of nanofibers in the foam material 3 is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com