Flaky structure layered composite hydroxide and preparation method thereof

A sheet-like structure, hydroxide technology, applied in the field of layered composite hydroxide and its preparation, can solve the problems of inconvenient industrial production, complicated post-processing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

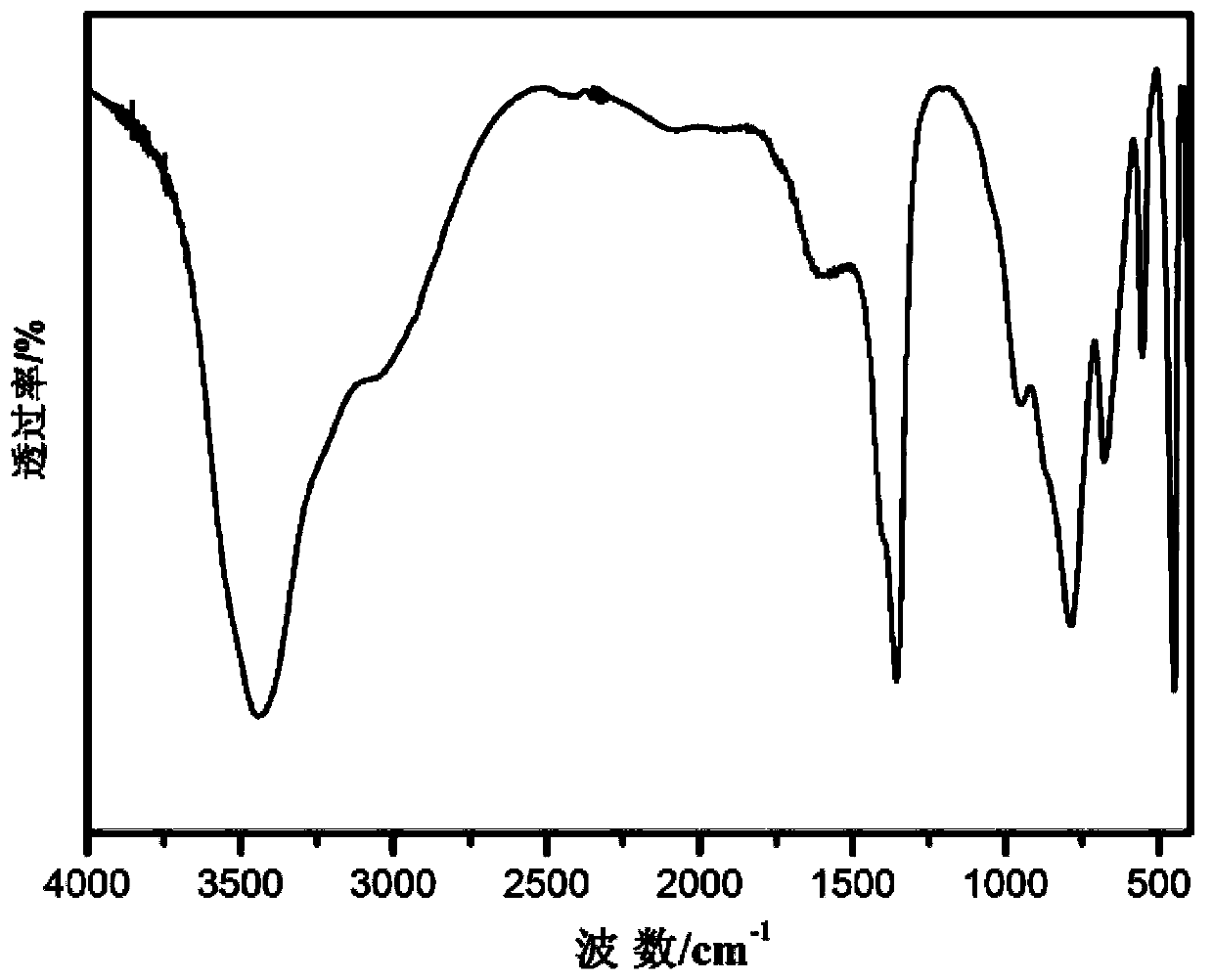

Image

Examples

Embodiment 1

[0030] Step A: Weigh 0.78g Al(OH) 3 Add it into 50ml of deionized water, grind it in a colloid mill for 15 minutes, and prepare a 15.6g / L slurry.

[0031] Step B: take by weighing 5.128g Mg(NO 3 ) 2 ·6H 2 O was added to the slurry prepared in step A, and mixed uniformly to obtain Mg(NO 3 ) 2 and Al(OH) 3 of the mixture.

[0032] Step C: Weigh 4.8g of urea and 0.2g of NaOH into 40ml of deionized water to prepare a solution.

[0033] Step D: Add the solution prepared in step C to the mixed solution in step B at 90°C with stirring, then continue to stir and react at 100°C for 24 hours, cool the slurry to room temperature after the reaction, and centrifugally wash the precipitate When the pH value is less than 8, dry the sample in an oven at 100°C for 12 hours to obtain the LDH product. Elemental analysis shows that the chemical composition formula of the product is: Mg 0.66 al 0.34 (OH) 2 (CO 3 ) 0.17 0.74H 2 O, using the BET specific surface area test method to mea...

Embodiment 2

[0035] Step A: Weigh 1.16g Mg(OH) 2 Add it into 100ml of deionized water, grind the slurry in a colloid mill for 10min, and prepare a slurry of 11.6g / L.

[0036] Step B: take by weighing 3.75g Al(NO 3 ) 3 9H 2 O is added to the slurry prepared in step A, and mixed evenly to obtain Mg(OH) 2 and Al(NO 3 ) 3 of the mixture.

[0037] Step C: Weigh 0.8g NaOH and 2.12g Na 2 CO 3 Add to 40ml deionized water to prepare a solution.

[0038] Step D: Add the solution prepared in step C dropwise to the mixture prepared in step B within 6 hours under stirring at 100°C, continue to stir and react at 100°C for 12 hours after the dropwise addition, and cool the slurry after the reaction After reaching room temperature, the precipitate was centrifuged, washed with water until the pH value was less than 8, filtered and dried. Elemental analysis shows that the chemical composition formula of the product is: Mg 0.66 al 0.34 (OH) 2 (CO 3 ) 0.17 0.59H 2 O, BET analysis shows that it...

Embodiment 3

[0040] Step A: take by weighing 1.2g pseudo-boehmite (Al 2 o 3 ·H 2 O) Add it into 100ml deionized water, grind the slurry in a ball mill for 5min, and prepare a 6g / L slurry.

[0041] Step B: Weigh 0.6894g LiNO 3 Add to the slurry prepared in step A, mix well to obtain LiNO 3 and Al 2 o 3 ·H 2 O mixture.

[0042] Step C: Weigh 4.8g of urea and add it into 20ml of deionized water to prepare a solution.

[0043] Step D: Add the solution prepared in step C to the mixture prepared in step B at 90°C with stirring, then continue to stir and react at 100°C for 24 hours, cool the slurry to room temperature after the reaction, centrifuge the precipitate, Wash with water until the pH value is less than 8, filter and dry to obtain the LDH product. Elemental analysis shows that the chemical composition formula of the product is: Li 0.34 al 0.66 (OH) 2 (CO 3 ) 0.17 0.57H 2 O, BET analysis shows that its specific surface area is 145.5m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com