Electrostatic salt fog removal device

A salt spray and electrostatic technology, applied in the field of electrostatic salt spray, can solve the problem of not causing domestic production enterprises, and achieve the effects of avoiding spark discharge damage, low failure rate and large capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

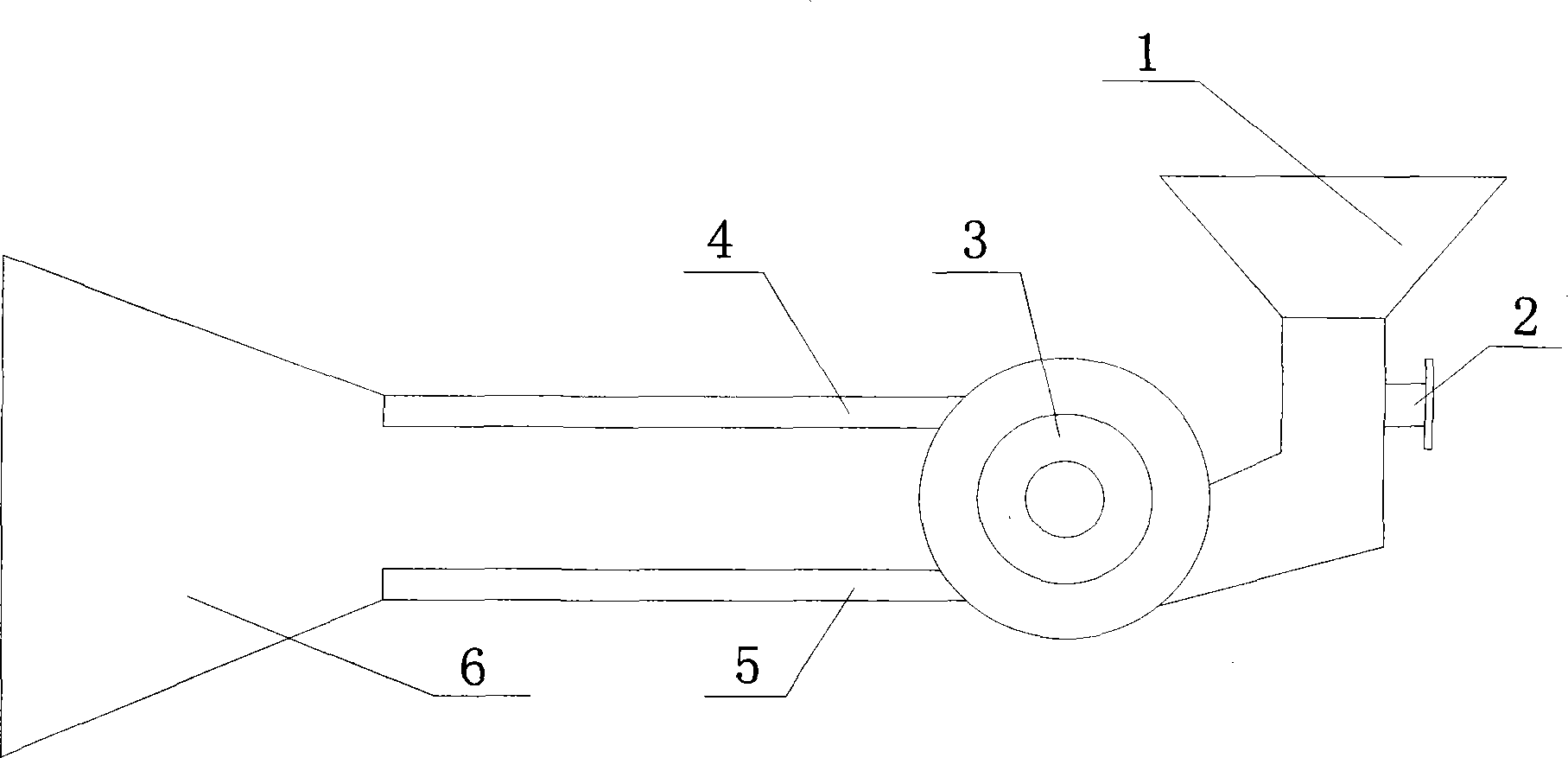

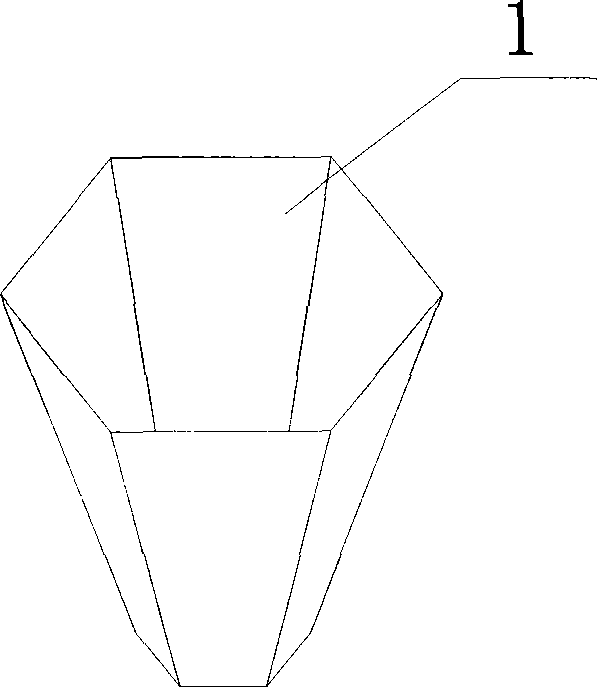

[0021] Such as figure 1 with figure 2 As shown, the electrostatic mist remover of the present invention includes a power supply, a plastic pipe, a discharge electrode and a fog collector, the fog collector is connected to the air inlet of the plastic pipe, and the discharge electrode includes a positive discharge electrode 4 and Discharge negative pole 5, the discharge positive pole 4 and the discharge negative pole 5 are all installed in the plastic pipe, and the discharge positive pole 4 and the discharge negative pole 5 are stainless steel tubes of hexagonal star teeth. The positive discharge electrode 4 and the negative discharge electrode 5 are stainless steel tubes with hexagonal star teeth, so that the discharge electrodes have better discharge performance, large capacitance, strong rigidity, and corrosion resistance. The fog collector includes an air inlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com