Edible mushroom matrix processing device and processing system

A substrate processing and processing device technology, which is applied in the field of edible fungus substrate processing devices and processing systems, can solve the problems of easy pollution costs, long time, cumbersome and complicated processes, etc., to solve incomplete sterilization, save energy and cost, The effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

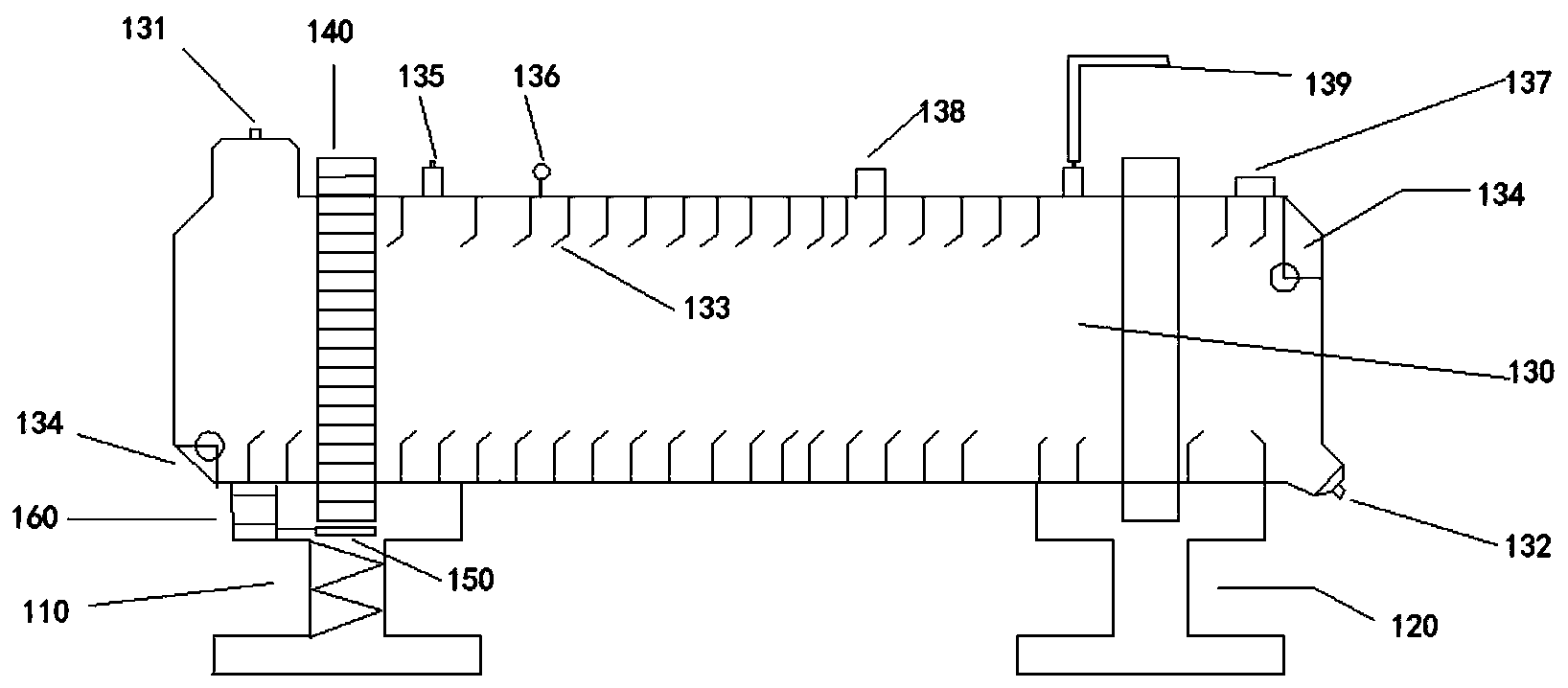

[0044] according to figure 1 The shown edible fungus substrate treatment device of the present invention comprises: a first support frame 110; a second support frame 120; a cylinder 130, which is a sealed cylindrical cylinder, and the cylinder 130 is horizontally installed on the first On the support frame 110 and the second support frame 120, the first support frame 110 is located below the first end of the cylinder body 130, and the second support frame 120 is located below the second end of the cylinder body 130; the cylinder body 130 includes: a feed inlet 131 and an outlet The material inlet 132 and the material inlet 131 are arranged above the first end of the cylinder body 130, and the material outlet 132 is arranged below the first end of the cylinder body 130; the cylinder body 130 further includes a frying plate 133, and the first end of the frying plate 133 is fixed On the inner wall of the cylinder 130, the second end points to the central axis of the cylinder 130;...

Embodiment 2

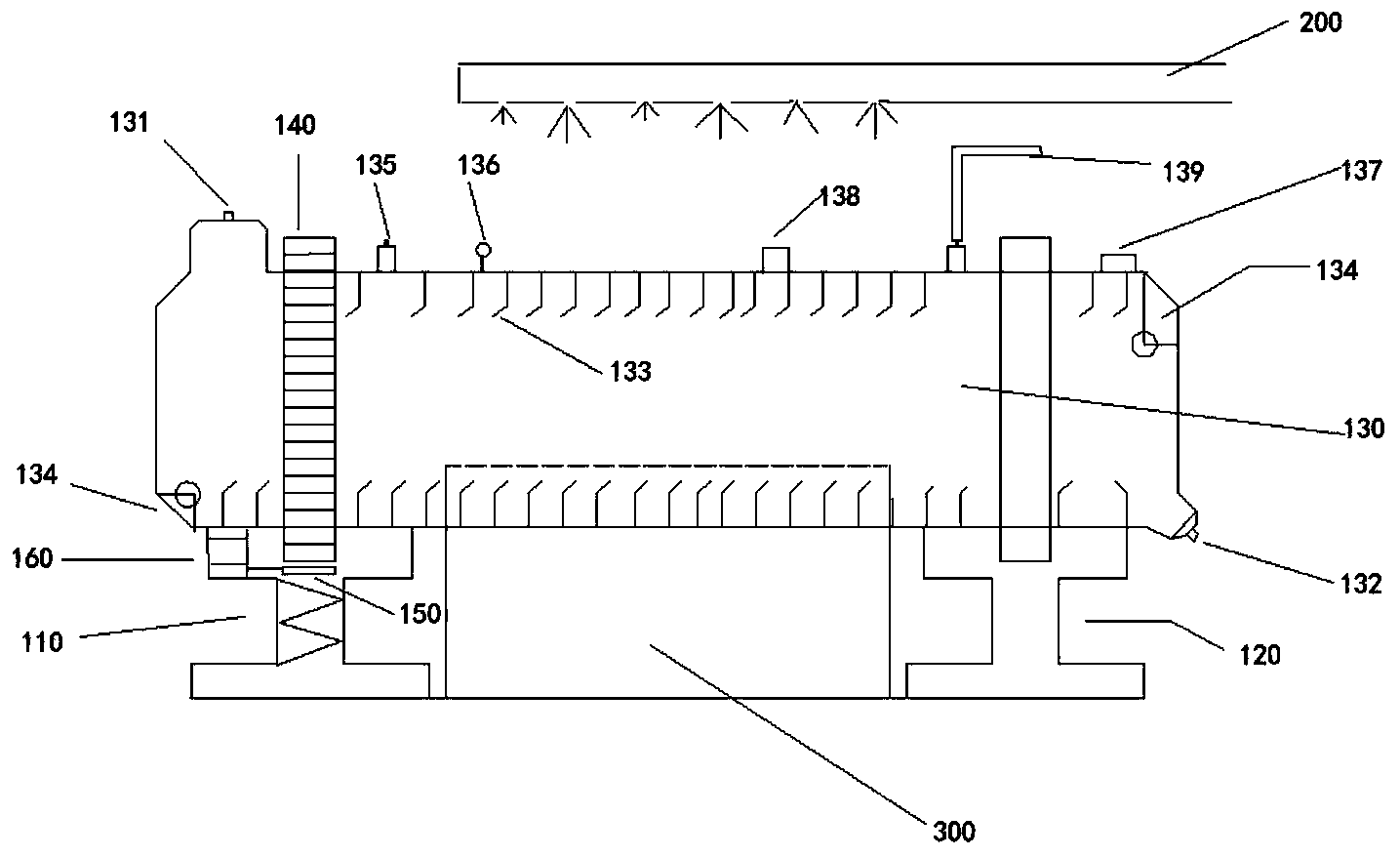

[0047] according to figure 2 The processing system of the shown edible fungus matrix includes: the edible fungus matrix processing device 100, the cooling water spray pipe 200 arranged in parallel with the cylinder 130 on the top of the edible fungus substrate processing device and the The tank body 300 at the lower part of the cylinder body 130 .

[0048] Wherein the edible fungus substrate treatment device comprises: a first support frame 110; a second support frame 120; a cylinder body 130, the cylinder body 130 is a sealed cylindrical drum, and the cylinder body 130 is horizontally installed on the first support frame 110 and the second support frame 120, the first support frame 110 is located below the first end of the cylinder 130, and the second support frame 120 is located below the second end of the cylinder 130; the cylinder 130 includes: a feed port 131 and a discharge port 132, and the feed port 131 It is arranged above the first end of the cylinder 130, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com