Gas diffusion layer with water retaining property for fuel cell, preparation method of gas diffusion layer, membrane electrode assembly and application

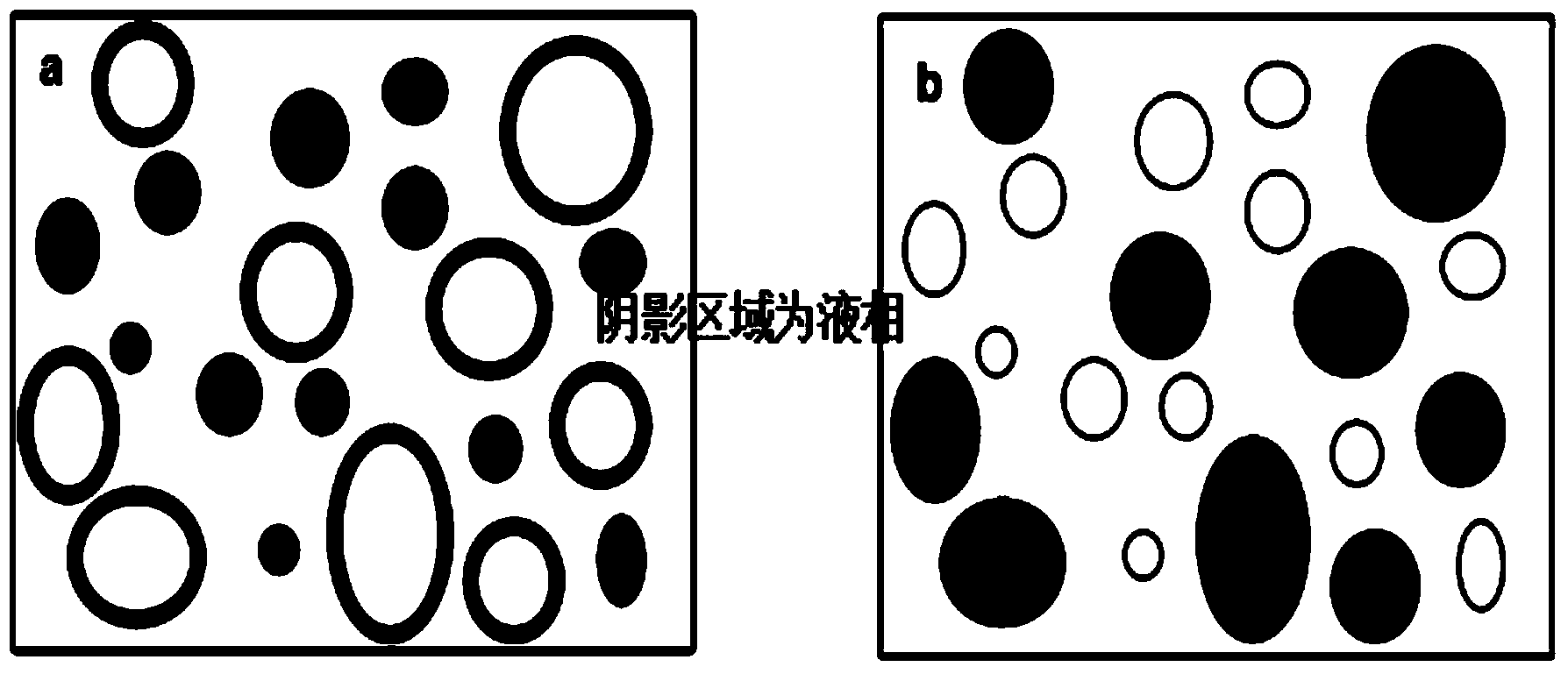

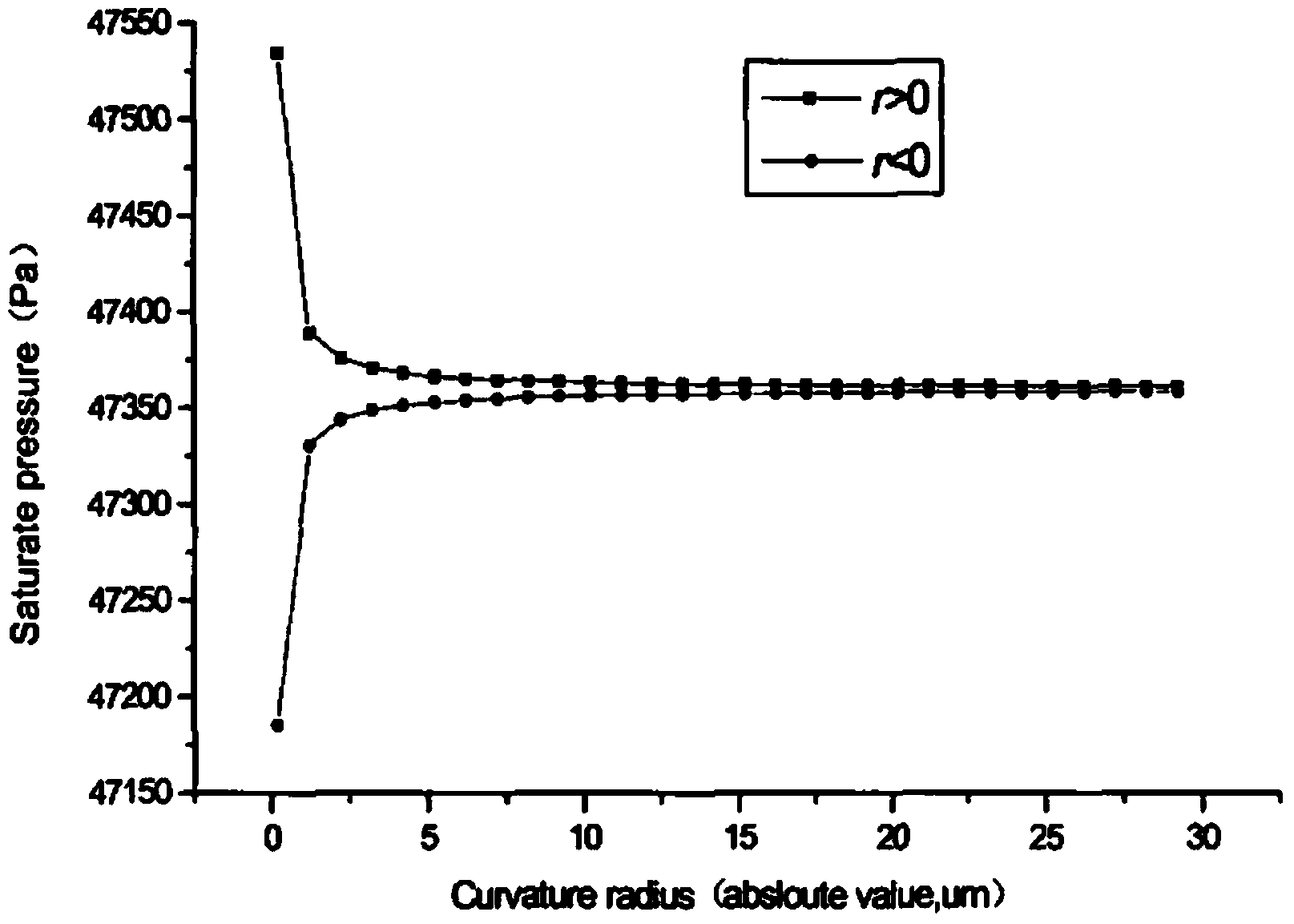

A gas diffusion layer and fuel cell technology, which is applied to fuel cell components, fuel cells, battery electrodes, etc., to achieve the effects of good water retention, reduced volatilization, and improved water retention and self-humidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

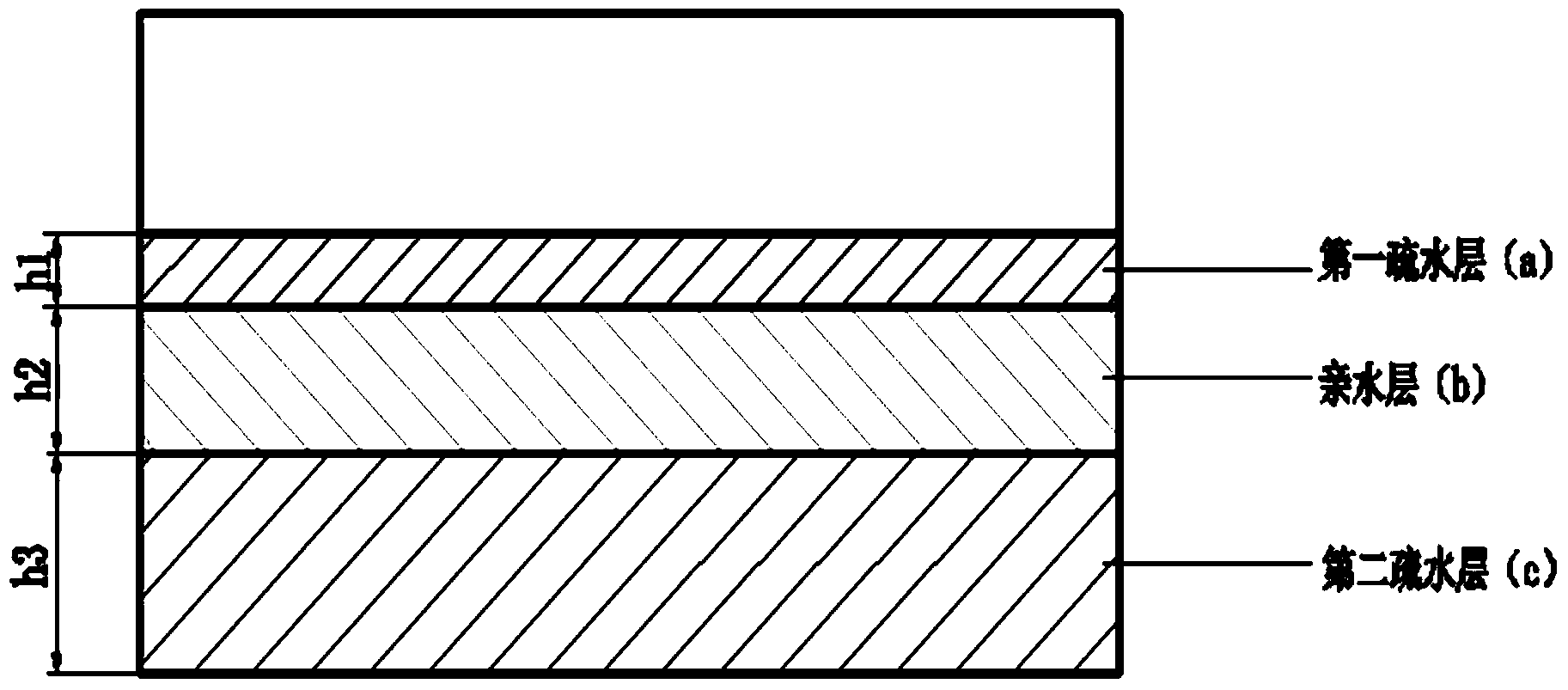

[0039] This embodiment provides a method for preparing a fuel cell gas diffusion layer with water retention, which includes the following steps:

[0040] 1) Dilute the polytetrafluoroethylene emulsion (mass concentration is 80%) to 15%, then put the carbon paper 0.35mm thick into the prepared polytetrafluoroethylene (PTFE) emulsion for 8 minutes, take it out, and let it air in the air 10min, then put it into an oven at 100°C and dry it for 20min to obtain a pretreated hydrophobic carbon paper with a degree of hydrophobicity of 30%, which is set aside;

[0041] 2) 18.00 g of perfluorosulfonic acid resin (Nafion PFSA5% Dispersions D520 of Dupond Company) solution with a solid content of 10%, carbon powder 2.7 g, and deionized water 3.6 g are made into a hydrophilic layer solution for subsequent use; The mass percentage of perfluorosulfonic acid resin is 40%;

[0042] 3) Dilute the polytetrafluoroethylene emulsion to a mass fraction of 20%, take 6.88g graphitized carbon powder, ...

Embodiment 2

[0046] This embodiment provides a method for preparing a fuel cell gas diffusion layer with water retention, which includes the following steps:

[0047] 1) Dilute the polytetrafluoroethylene emulsion (mass concentration is 80%) to 15%, then put the carbon paper 0.35mm thick into the prepared polytetrafluoroethylene (PTFE) emulsion for 8 minutes, take it out, and let it air in the air 10min, then put it into an oven at 100°C and dry it for 20min to obtain a pretreated hydrophobic carbon paper with a degree of hydrophobicity of 30%, which is set aside;

[0048] 2) 18.00 g of perfluorosulfonic acid resin (Nafion PFSA5% Dispersions D520 of Dupond Company) solution with a solid content of 10%, carbon powder 7.2 g, and deionized water 3.6 g are made into a hydrophilic layer solution for subsequent use; The mass percentage of perfluorosulfonic acid resin is 20%;

[0049] 3) Dilute the polytetrafluoroethylene emulsion to a mass fraction of 20%, take 6.88g of graphitized carbon powde...

Embodiment 3

[0053] This embodiment provides a method for preparing a fuel cell gas diffusion layer with water retention, which includes the following steps:

[0054] 1) Dilute the polytetrafluoroethylene emulsion (mass concentration is 80%) to 15%, then put the carbon paper 0.35mm thick into the prepared polytetrafluoroethylene (PTFE) emulsion for 8 minutes, take it out, and let it air in the air 10min, then put it into an oven at 100°C and dry it for 20min to obtain a pretreated hydrophobic carbon paper with a degree of hydrophobicity of 30%, which is set aside;

[0055]2) 18.00 g of perfluorosulfonic acid resin (Nafion PFSA5% Dispersions D520 of Dupond Company) solution with a solid content of 10%, carbon powder 2.7 g, and deionized water 3.6 g are made into a hydrophilic layer solution for subsequent use; The mass percentage of perfluorosulfonic acid resin is 40%;

[0056] 3) Dilute the polytetrafluoroethylene emulsion to a mass fraction of 20%, take 6.88g of graphitized carbon powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com