A low-loss large effective area single-mode optical fiber and its manufacturing method

A single-mode fiber, effective area technology, used in cladding fibers, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of increasing process complexity and manufacturing cost, and achieve the effect of low loss and large effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

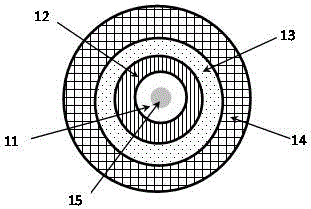

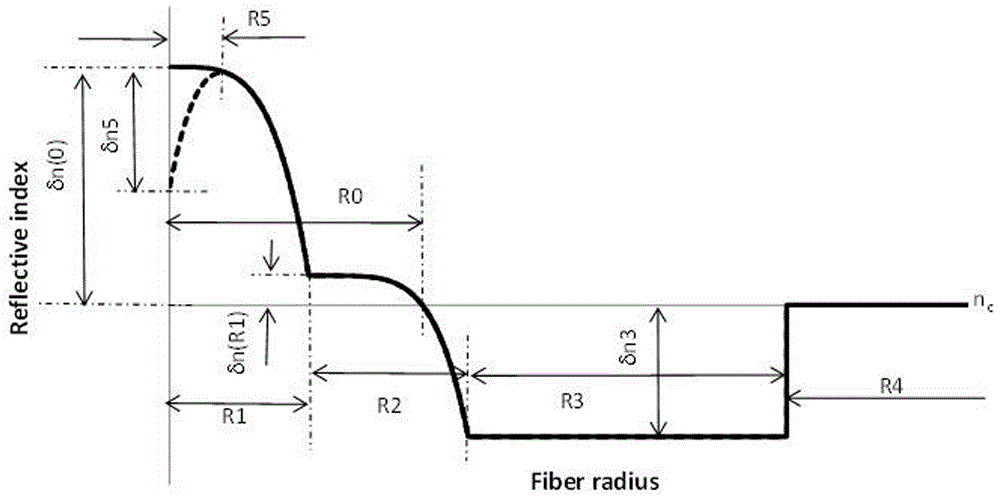

[0062] refer to Figure 1A and Figure 1B , the fiber consists of 4 parts from the center to the outside:

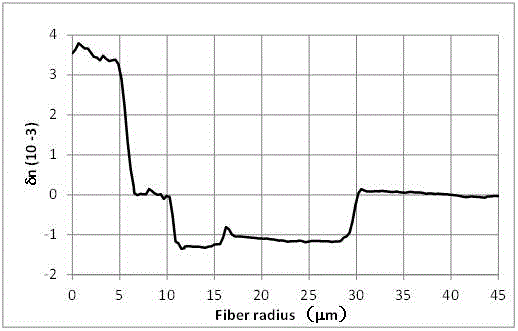

[0063] 1) Core region 11: the radius extending outward from the center is R 1 . The main doping component is germanium, and there may also be a small amount of fluorine. R 1 The range is 4μm~9μm; its typical value is 5.7μm~8.2μm. The refractive index difference in the core area and the fiber radius r have the following relationship:

[0064] . (0≤r1 )

[0065] where δn(0) is the refractive index difference at the center of the fiber, and its range is 2.2x10 -3 ~5.8x10 -3 , the typical value is 2.6x10 -3 ~5.3x10 -3 . In order to make the fiber attenuation below 0.185dB / km at 1550nm, δn(0) must be below 4.5x10 -3 , preferably need to be lower than 4.0x10 -3 . δn(R 1 ) is the refractive index difference at the edge of the core region, δn(R 1 )-3 ~-0.5x10 -3. α is the distribution power of the fiber core, and its range is α≥1.5.

[0066] Central depress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| dispersion value | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com