Hot air circulating system of textile drying room

A circulation system and drying room technology, applied in drying, drying machines, lighting and heating equipment, etc., can solve the problems of hot air not being able to be recycled, low thermal efficiency, high energy consumption, etc., to achieve improved uniformity, improved thermal efficiency, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

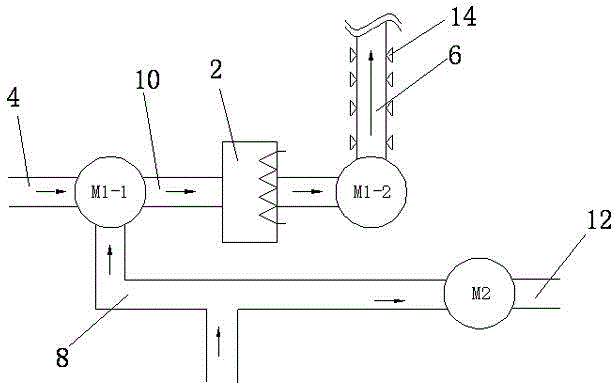

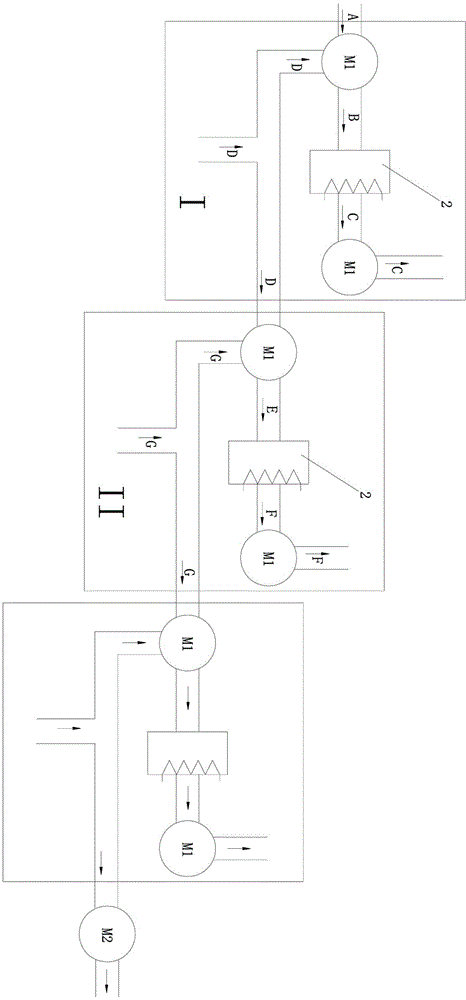

[0016] Such as figure 1 As shown, a hot air circulation system of a fabric drying room includes an air supply pipe with air inlets and air outlets at both ends, a circulation fan M1 and an exhaust fan M2 for guiding the air in the air supply pipe, and The heater 2 that heats the air in the air duct, and the air supply duct includes an air inlet duct 4 communicated with the air outside the drying room, an air outlet duct 6 and a return air duct 8 communicated with the air in the oven room, and an air inlet duct connected with the air. The air guide pipe 10 of the pipe 4 and the air outlet pipe 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com