Preparation method of intermediate strength aluminum alloy monofilament

A medium-strength aluminum alloy and aluminum alloy monofilament technology, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, power cables, etc., can solve the problems of high cost, complex production process of medium-strength aluminum alloy, product mechanical properties and electrical conductivity Poor problems, to achieve the effect of improving conductivity, increasing work intensity, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

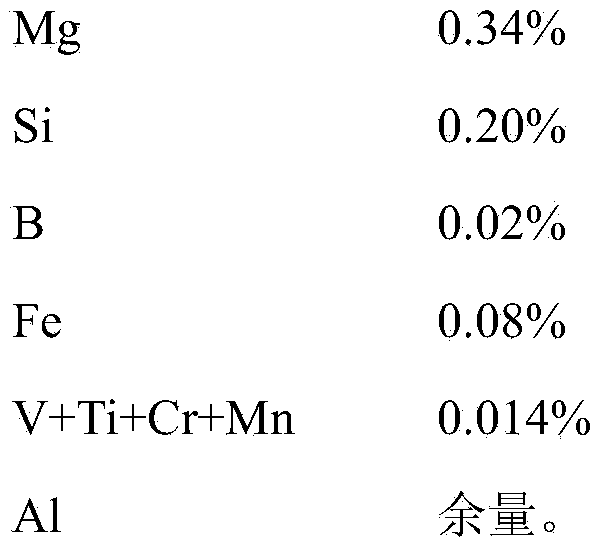

[0028] The composition and weight percentage of the aluminum alloy material are:

[0029]

[0030] The specific preparation method is:

[0031] (1) Smelting: select industrial pure aluminum ingots with a purity of 99.7% and add them to the melting furnace at a melting temperature of 730°C; after the pure aluminum is completely melted, add Al-B, Al-Mg and Al-Si master alloys at 740°C to make Their final contents are shown above,

[0032] (2) Refining: use a mixer to fully stir the molten aluminum, use a refining agent for the molten aluminum to degas and remove slag, the refining temperature of the molten aluminum alloy is 740°C, and stand for 40 minutes.

[0033] (3) Casting: put the aluminum liquid obtained in step 2) at 715°C, put the low-carbon steel mold into a box furnace and heat it to 220°C, pour the aluminum liquid into the cylindrical mold, and prepare a Ф80 × 100mm long cylindrical aluminum ingot.

[0034](4) Rod making: the round aluminum ingot is extruded int...

Embodiment 2

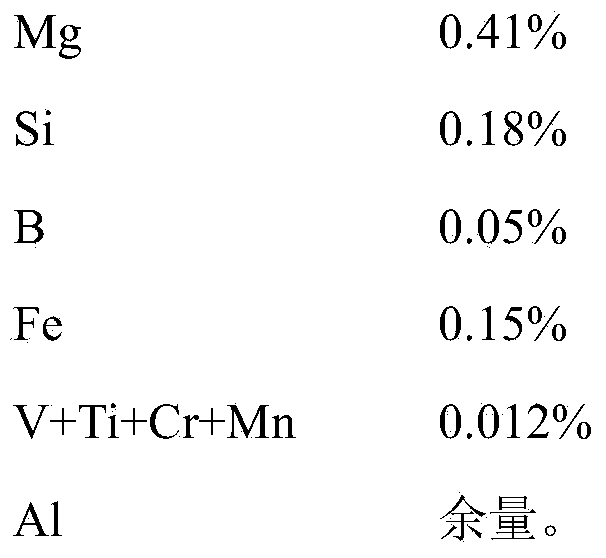

[0038] A medium-strength aluminum alloy material with an electrical conductivity of 59%IACS, the components and their weight percentages are:

[0039]

[0040] The specific preparation method is:

[0041] (1) Smelting: select industrial pure aluminum ingots with a purity of 99.7% and add them to the melting furnace at a melting temperature of 750°C; after the pure aluminum is completely melted, add Al-B, Al-Mg and Al-Si master alloys at 750°C to make Their final contents are shown above,

[0042] (2) Refining: use a mixer to fully stir the aluminum liquid, use aluminum liquid refining agent to degas and remove slag, the aluminum alloy liquid refining temperature is 730°C, and stand for 40 minutes.

[0043] (3) Casting: put the aluminum liquid obtained in step 2) at 720°C, put the low-carbon steel mold into a box furnace and heat it to 200°C, pour the aluminum liquid into the cylindrical mold, and prepare a Ф80 × 100mm long cylindrical aluminum ingot.

[0044] (4) Rod mak...

Embodiment 3

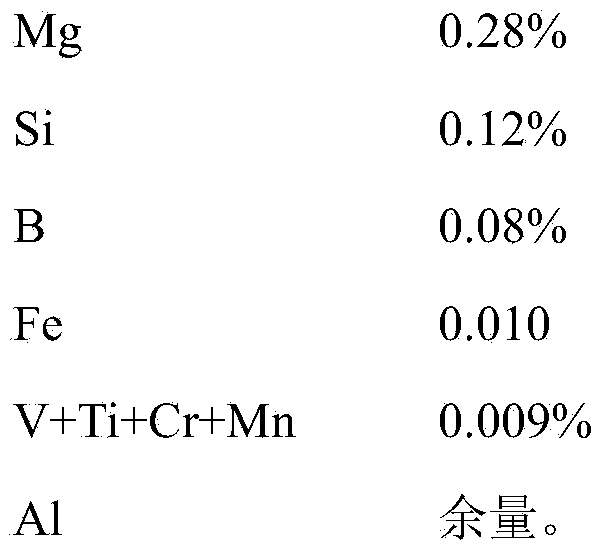

[0048] A medium-strength aluminum alloy material with an electrical conductivity of 59%IACS, the components and their weight percentages are:

[0049]

[0050] The specific preparation method is:

[0051] (1) Smelting: select industrial pure aluminum ingots with a purity of 99.7% and add them to the melting furnace at a melting temperature of 720°C; after the pure aluminum is completely melted, add Al-B, Al-Mg and Al-Si master alloys at 730°C to make Their final contents are shown above,

[0052] (2) Refining: use a mixer to fully stir the aluminum liquid, use aluminum liquid refining agent to degas and remove slag, the aluminum alloy liquid refining temperature is 730°C, and stand for 40 minutes.

[0053] (3) Casting: put the aluminum liquid obtained in step 2) at 715°C, put the low-carbon steel mold into a box furnace and heat it to 220°C, pour the aluminum liquid into the cylindrical mold, and prepare a Ф80 × 100mm long cylindrical aluminum ingot.

[0054] (4) Rod mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com